To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Our SHUTTER MAKING Roll Forming Machine is a high-performance, fully automated solution designed for the production of rolling shutter slats. Tailored for the UAE market, it accommodates various materials and profiles, ensuring versatility and efficiency in manufacturing operations.

Machine Type: Fully Automatic Rolling Shutter Slat Roll Forming Machine

Production Speed: Up to 30 meters per minute

Material Thickness Range: 0.4 mm – 1.6 mm

Material Width Range: 135 mm – 215 mm

Material Types: Galvanized Steel (GI), Pre-painted Galvanized Iron (PPGI), Galvalume (GL), Aluminum

Material Yield Strength: 250 – 550 MPa

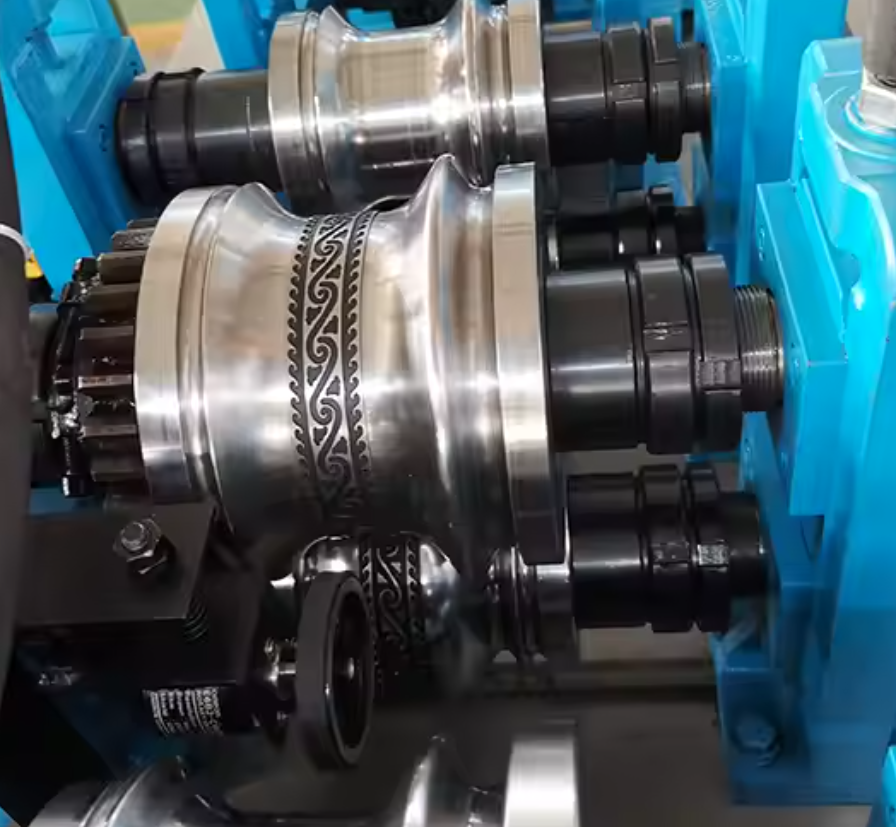

Roller Material: 45# Steel, quenched and hard chrome plated

Roller Surface Treatment: Hard chrome coating with HRC58–62 hardness

Number of Forming Stations: 12 – 22 stations

Roller Shaft Diameter: 65 mm – 90 mm

Shaft Material: 45# Steel, precision machined

Main Drive Type: Chain or Gearbox Drive

Power Supply: 380V, 50Hz, 3-phase (customizable)

Motor Power: 5.5 kW – 11 kW

Cutting Method: Hydraulic Post-Cutting

Blade Material: Cr12MoV, heat-treated

Control Type: PLC Control with HMI Touchscreen

Operating Mode: Fully Automatic

De-coiling System: Manual or Hydraulic Decoiler (optional)

Punching/Notching System: Hydraulic Punching Station (optional)

Machine Frame: Welded Steel Frame with 16 mm – 30 mm Thickness

Thickness of Frame Steel: 16 mm – 30 mm

Profile Shape: Customizable according to client requirements

Profile Width and Depth: As per client's profile drawings

Length Tolerance: ±1 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Our roll forming machines cater to a diverse range of industries, including:

Construction: Manufacturing of rolling shutters for commercial and residential buildings.

Industrial Manufacturing: Production of industrial doors and partitions.

Automotive: Fabrication of vehicle rolling doors and security shutters.

Warehousing & Logistics: Creation of storage facility doors and enclosures.

The SHUTTER MAKING Roll Forming Machine is designed for high-speed, continuous production of rolling shutter slats. It offers

High Precision: Ensures consistent quality and dimensions.

Versatility: Capable of producing various profiles and accommodating different materials.

Efficiency: Reduces manual labor and increases production rates.

We offer extensive customization to meet specific client needs:

Profile Design: Machines can be tailored to produce specific slat profiles as per provided drawings.

Material Compatibility: Adjustments for different material types and thicknesses.

Automation Level: Options for semi-automatic or fully automatic operation.

Additional Features: Integration of punching, embossing, or notching systems.

Starting Price: Approximately USD 37,000 per unit.

Factors Affecting Price: Customization level, optional features, and specific client requirements.

Lead Time: Production typically takes 30–60 days. Shipping time depends on the destination port.

Delivery: Machines can be delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

Q: Can the machine be customized for our profile?

A: Yes, we offer customization based on your specific profile drawings and requirements.

Q: What type of material is normally used with this machine?

A: Common materials include Galvanized Steel (GI), Pre-painted Galvanized Iron (PPGI), Galvalume (GL), and Aluminum, with thicknesses ranging from 0.4 mm to 1.6 mm and yield strengths between 250 – 550 MPa.

Q: Is remote installation support available?

A: Yes, we offer remote video guidance, and on-site installation is available upon request.

Q: What is the lead time for manufacturing and shipping?

A: Production typically takes 30–60 days, and shipping time depends on the destination port.

High Efficiency: Achieves production speeds up to 30 meters per minute, enhancing productivity.

Robust Construction: Built with high-quality materials ensuring durability and long service life.

Advanced Automation: Equipped with PLC control and HMI touchscreen for easy operation.

Comprehensive Safety Features: Includes protective covers, emergency stop buttons, and overload protection systems.

Customization Flexibility: Tailored solutions to meet specific client requirements.

All machines come with a one-year warranty from the date of dispatch. We provide durable maintenance and repair support to ensure uninterrupted operation.

For a tailored quote or more information, please email your profile drawings and requirements to:

📧 [email protected]

Copyright 2026 © Machine Matcher.