To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

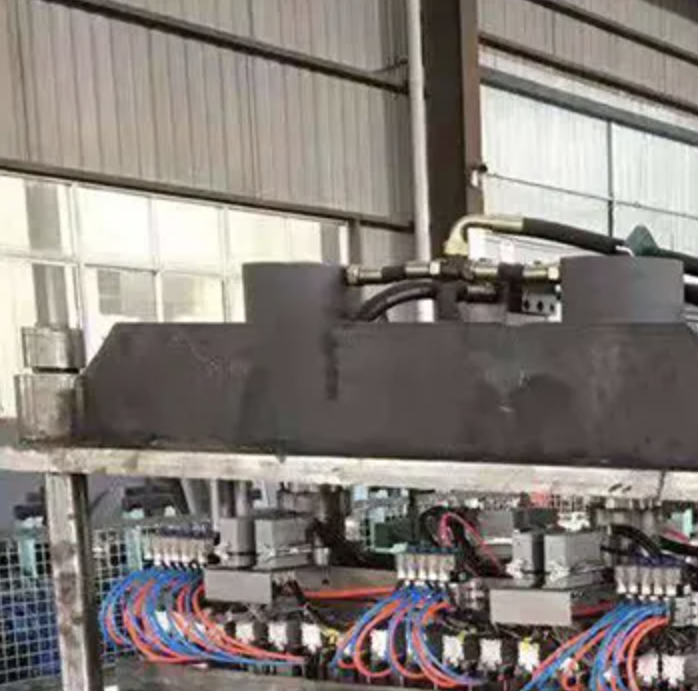

A silo roll forming machine is specialized equipment designed to produce metal sheets or panels for constructing silos used for storage in agriculture, industrial, and other applications. Here’s a breakdown of its specifications and description:

Silo roll forming machines produce the cylindrical metal panels and roof panels essential for constructing silos. These panels must be sturdy, weather-resistant, and capable of supporting heavy loads over time. Due to the heavy-duty nature of silos, these machines are equipped to handle thicker metals, ensuring that each panel meets the specific requirements for storage units, particularly in agriculture (grain storage) and industrial sectors (cement, chemical storage).

Copyright 2026 © Machine Matcher.