To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

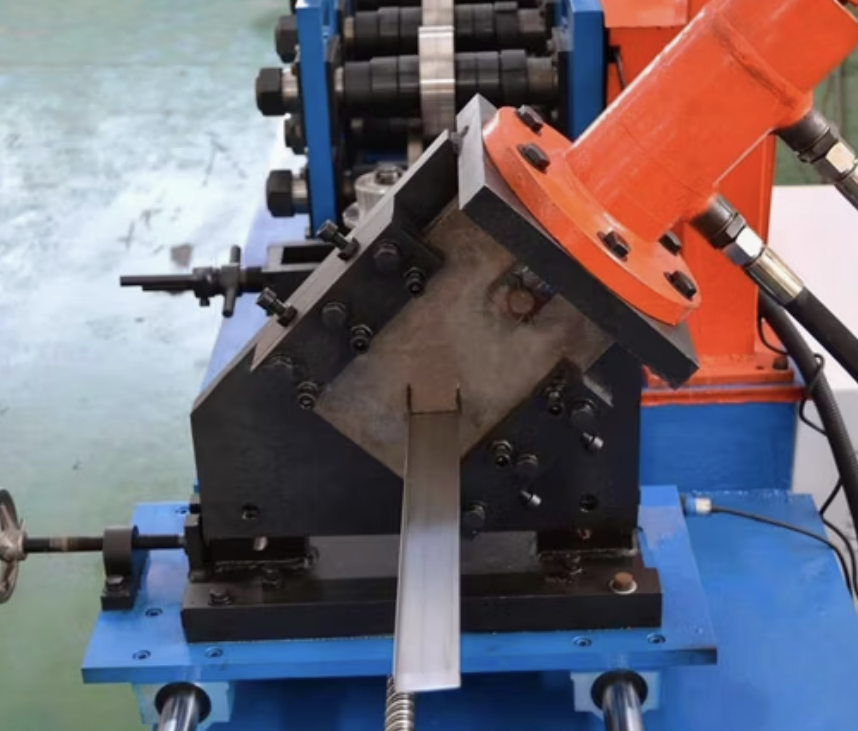

The Slotted Channel Roll Forming Machine is a high-precision, heavy-duty production solution designed to manufacture metal slotted channels used in electrical support systems, cable trays, framing systems, and construction applications. Built for industrial performance and efficiency, this machine delivers consistent quality at high speeds to meet the growing demands of the UAE's dynamic building and infrastructure sectors.

Manufactured with the latest technology and engineered to endure heavy-duty production conditions, our slotted channel roll forming machines are new, custom-built to customer specifications, and can be delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and surrounding areas.

If you need a reliable solution for mass production of slotted channels, this machine offers superior performance, durability, and precision.

Machine Type: Slotted Channel Roll Forming Machine

Production Speed: 10–20 meters per minute (depending on profile complexity)

Material Thickness Range: 1.0 mm – 2.5 mm

Material Width Range: 50 mm – 300 mm

Material Types: Galvanized Steel, Mild Steel, Stainless Steel, Aluminum

Material Yield Strength: Up to 350 MPa

Roller Material: GCr15 bearing steel

Roller Surface Treatment: Hard Chrome Coated (≥0.05mm thickness)

Number of Forming Stations: 12–18 stations (depending on profile design)

Roller Shaft Diameter: 60 mm

Shaft Material: High-Strength 45# Steel, precision-ground

Main Drive Type: Gearbox and Chain Drive System

Power (for UAE voltage 380V/50Hz/3Phase): Fully compliant

Motor Power: 11 kW

Cutting Method: Hydraulic cutting, non-stop flying cut system

Blade Material: Cr12Mov mold steel, heat-treated

Control Type: PLC control system (Mitsubishi, Siemens, or Delta as per customer choice)

Operating Mode: Fully Automatic Operation

De-coiling System: Hydraulic De-coiler (5 tons capacity optional)

Punching/Notching System: Hydraulic punching unit included (with customizable punching dies)

Machine Frame: Heavy-duty H-Beam welded structure

Thickness of Frame Steel: 18 mm

Profile Shape: U-shaped or C-shaped slotted channel with holes

Profile Width and Depth: Customizable per customer drawing (common width: 41mm; depth: 21mm/41mm/62mm)

Length Tolerance: ±2.0 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

The Slotted Channel Roll Forming Machine is ideal for industries such as:

Electrical Support Systems (Cable Tray, Conduit Support)

Construction and Building Material Suppliers

Solar Panel Mounting Structures

HVAC and Mechanical Installations

Retail and Commercial Interior Fit-outs

General Fabrication and Structural Framing

Given the booming construction, renewable energy, and commercial development sectors across the UAE, having a reliable slotted channel production line ensures fast turnaround times, quality assurance, and higher profitability.

All machines are custom-built to meet each customer's specific profile and production requirements.

Delivery is available across all Emirates: Abu Dhabi, Dubai, Sharjah, Ajman, Fujairah, Ras Al Khaimah, and Umm Al Quwain.

Pricing: Pricing varies based on optional features such as automatic stackers, coil cars, customized punching dies, or additional forming stations.

📩 For a tailored quote, email your profile drawing and requirements to [email protected].

Each machine is backed by:

One-Year Warranty (from dispatch date)

Durable Maintenance and After-Sales Support

A: It is capable of processing galvanized steel, mild steel, stainless steel, and aluminum up to 2.5 mm thickness, ideal for the UAE's typical construction materials.

A: Yes, the machine can be customized to produce various widths and depths. Quick-change systems can also be included if multiple sizes are needed frequently.

A: Yes, a hydraulic punching unit is integrated into the line, allowing customizable punching patterns according to customer drawings.

A: The machine typically runs at 10–20 meters per minute, depending on material thickness and punching requirements.

A: Absolutely. The machine is supplied with 380V, 50Hz, 3 Phase system voltage to match UAE industrial standards.

A: Standard production time is 8–12 weeks, plus shipping and installation preparation. Express options may be available on request.

A: We can offer modular tooling or changeable cassettes depending on your future production expansion needs.

A: Simply send your slotted channel profile drawings, material details, production volume expectations, and any special requests to [email protected]. Our team will respond with a detailed quote and machine proposal.

For detailed specifications, quotes, or technical consultations:

Machine Matcher

📧 [email protected]

All machines are brand new, built to the highest industry standards, and supported by experienced technical teams in the UAE and internationally.

Copyright 2026 © Machine Matcher.