To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

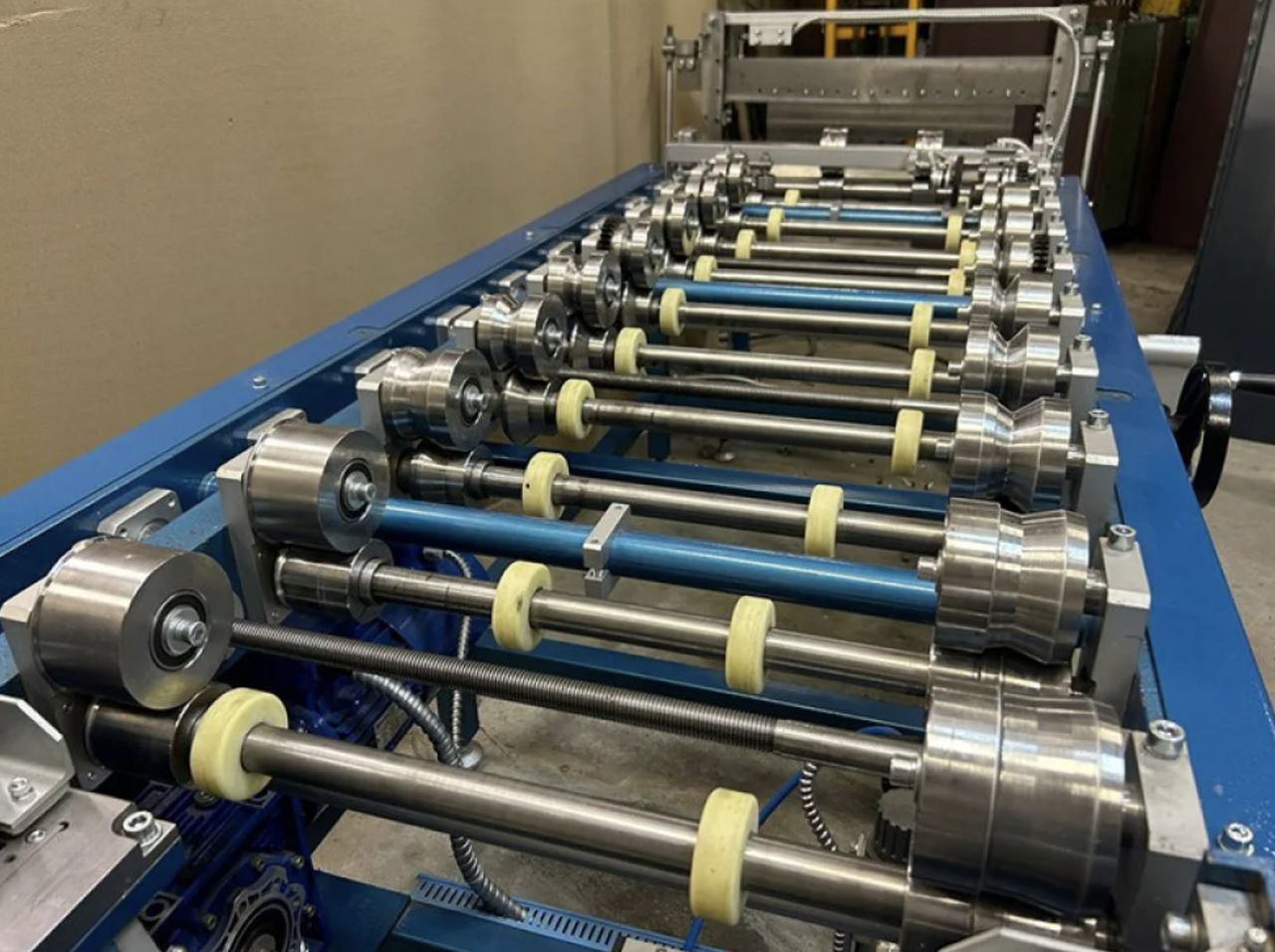

The Snap Lock Roofing Roll Forming Machine is designed to produce high-quality Snap Lock standing seam panels, a popular choice for modern roofing systems in Canada. These panels feature a concealed fastening system, offering superior durability, weather resistance, and a sleek appearance. This machine ensures efficient production, precision, and adaptability to meet the diverse demands of the Canadian roofing industry, including cold weather durability and aesthetic appeal for residential, commercial, and industrial applications.

1. Structural Features:

2. Driving and Control System:

3. Panel Production Capabilities:

4. Safety Features:

5. Optional Add-Ons:

Snap Lock roofing panels are particularly popular in the Canadian market due to their resistance to extreme weather conditions and aesthetic appeal. Applications include:

Q1: What is the primary advantage of Snap Lock roofing panels in the Canadian climate?

A: Snap Lock panels provide exceptional weather resistance, making them ideal for heavy snow loads, rain, and freezing temperatures common in Canada. The concealed fastening system prevents leaks and enhances durability.

Q2: What materials are compatible with this machine?

A: The Snap Lock Roll Forming Machine works with galvanized steel, aluminum, copper, and pre-painted steel, making it versatile for various Canadian roofing projects.

Q3: Can the machine be customized for specific panel sizes?

A: Yes, the machine is highly customizable. It can produce panels of different widths and heights to match specific project requirements.

Q4: How easy is it to operate and maintain the machine?

A: The machine features an advanced PLC system with a touchscreen interface for intuitive operation. Maintenance is straightforward, requiring regular lubrication and inspection of rollers and hydraulic systems.

Q5: Are there financing options available for Canadian buyers?

A: Many manufacturers and distributors offer flexible financing plans tailored to Canadian businesses. Check with your supplier for specific options.

Q6: What safety features are included?

A: The machine includes full safety enclosures, emergency stop systems, and overload protection to ensure operator safety and protect the equipment.

Q7: How does this machine handle energy efficiency?

A: The servo motors and PLC control system optimize energy usage, making the machine cost-effective for long-term operation.

This Snap Lock Roofing Roll Forming Machine is an ideal choice for Canadian manufacturers and contractors seeking efficiency, precision, and durability in roofing panel production. Its adaptability to the Canadian market ensures it meets local standards and project demands.

Copyright 2026 © Machine Matcher.