To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

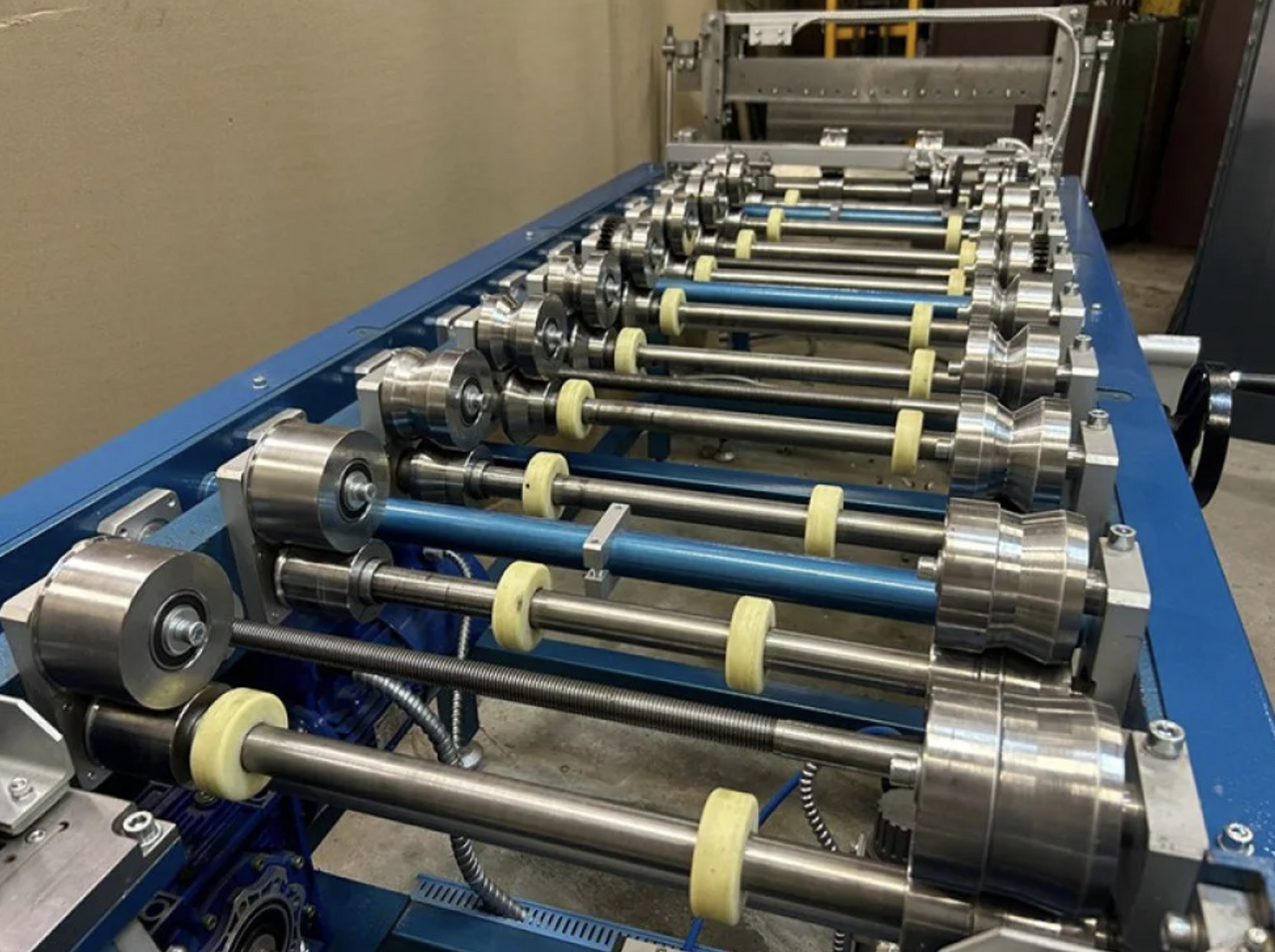

The Snap Lock Roofing Roll Forming Machine is a high-precision piece of equipment designed to produce snap lock roofing panels efficiently and accurately. These panels are popular for their ease of installation, durability, and aesthetic appeal, making them a preferred choice for residential and commercial buildings in Denmark. This blog provides a detailed overview of the machine, its specifications, and answers to common questions.

The Snap Lock Roofing Roll Forming Machine is engineered to manufacture snap lock panels from various metals such as galvanized steel, aluminum, and copper. These panels are known for their interlocking mechanism, eliminating the need for additional fasteners or clips during installation.

This machine integrates advanced features to ensure high productivity and quality, catering to the specific needs of the Danish roofing industry.

Regular maintenance is crucial for optimal machine performance:

The machine can process a variety of materials, including galvanized steel, aluminum, and copper, making it suitable for different roofing needs in Denmark.

The snap lock mechanism features interlocking edges on the roofing panels, allowing them to snap together without fasteners. This ensures a secure fit and a seamless appearance.

The machine can produce panels at speeds of up to 15-20 meters per minute, depending on the material type and profile complexity.

Yes, the rollers and cutting system are adjustable to cater to various panel widths.

Absolutely, the machine is equipped with safety guards, emergency stop functions, and complies with CE marking requirements.

Yes, the Snap Lock panels produced by this machine are ideal for both residential and commercial applications due to their durability, weather resistance, and aesthetic appeal.

The machine operates on a standard Danish power supply of 400V and 50Hz.

The Snap Lock Roofing Roll Forming Machine is a robust, versatile, and efficient solution for producing high-quality roofing panels in Denmark. Its advanced features and compliance with local standards make it an excellent investment for roofing contractors and manufacturers.

For inquiries or to request a quote, feel free to contact us with your specifications and requirements.

Copyright 2026 © Machine Matcher.