To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Snap lock roofing has become a favored roofing style in Ghana, especially in Accra, due to its weather resistance, modern aesthetic, and suitability for residential and commercial buildings. This roofing profile is known for its seamless installation process and long-term durability, making it an ideal choice for the country's tropical climate. To meet the growing demand for snap lock roofs, Snap Lock Roofing Roll Forming Machines are essential for producing high-quality roofing sheets efficiently and cost-effectively.

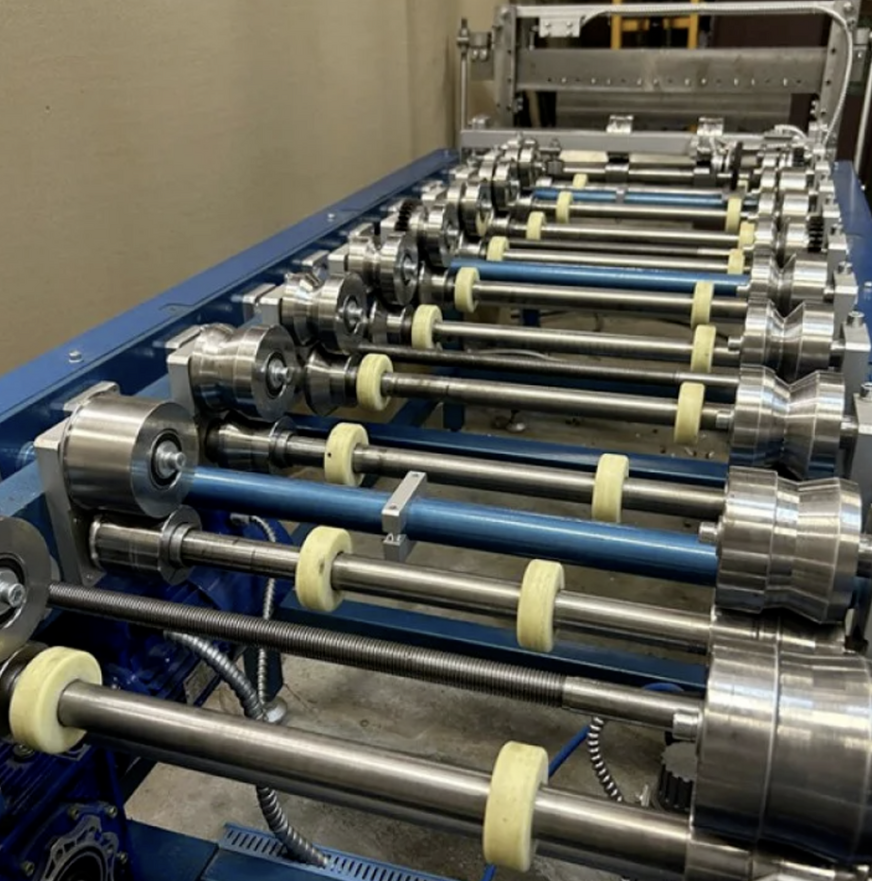

A Snap Lock Roofing Roll Forming Machine is an advanced industrial equipment designed to produce snap lock roofing panels from metal coils. These machines automate the manufacturing process, ensuring precision, consistency, and high production speeds. Snap lock panels are characterized by their interlocking design, which eliminates the need for mechanical fasteners, enhancing durability and aesthetics.

The Snap Lock Roofing Roll Forming Machine is delivered with complete installation services. The process includes:

Regular maintenance ensures longevity and consistent performance:

Q1: Why is snap lock roofing popular in Ghana?

A1: Snap lock roofing is popular in Ghana, particularly in Accra, because of its ability to withstand heavy rainfall and intense sunlight, providing durability and a sleek, modern appearance.

Q2: Can the machine accommodate different power supply standards?

A2: Yes, the machine can be customized for Ghana's 230V or 400V power supply.

Q3: What materials are suitable for use in this machine?

A3: The machine works with galvanized steel, aluminum, and pre-painted steel, with thicknesses ranging from 0.3 mm to 0.7 mm.

Q4: How many panels can this machine produce in a day?

A4: With a speed of up to 25 meters per minute, the machine can produce approximately 12,000 meters of panels in an 8-hour shift.

Q5: Is training provided for operating the machine?

A5: Yes, comprehensive training is included to ensure operators can use the machine efficiently and safely.

Q6: What are the shipping options for Ghana?

A6: Machines are shipped via sea freight to major ports like Tema, with delivery and installation services in Accra and other regions.

Conclusion

For Ghana’s fast-growing construction market, investing in a Snap Lock Roofing Roll Forming Machine is a strategic choice for manufacturers aiming to meet the demand for high-quality roofing solutions. The machine's efficiency, precision, and adaptability to local requirements make it an invaluable asset in the roofing industry.

Copyright 2026 © Machine Matcher.