To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

With Nigeria's construction sector on a steady rise, the demand for high-quality, durable roofing solutions has grown significantly. Among these, snap lock roofing profiles have become a popular choice for both residential and commercial buildings. Known for their durability, modern aesthetics, and ease of installation, these profiles offer an ideal roofing solution for upscale developments and commercial properties.

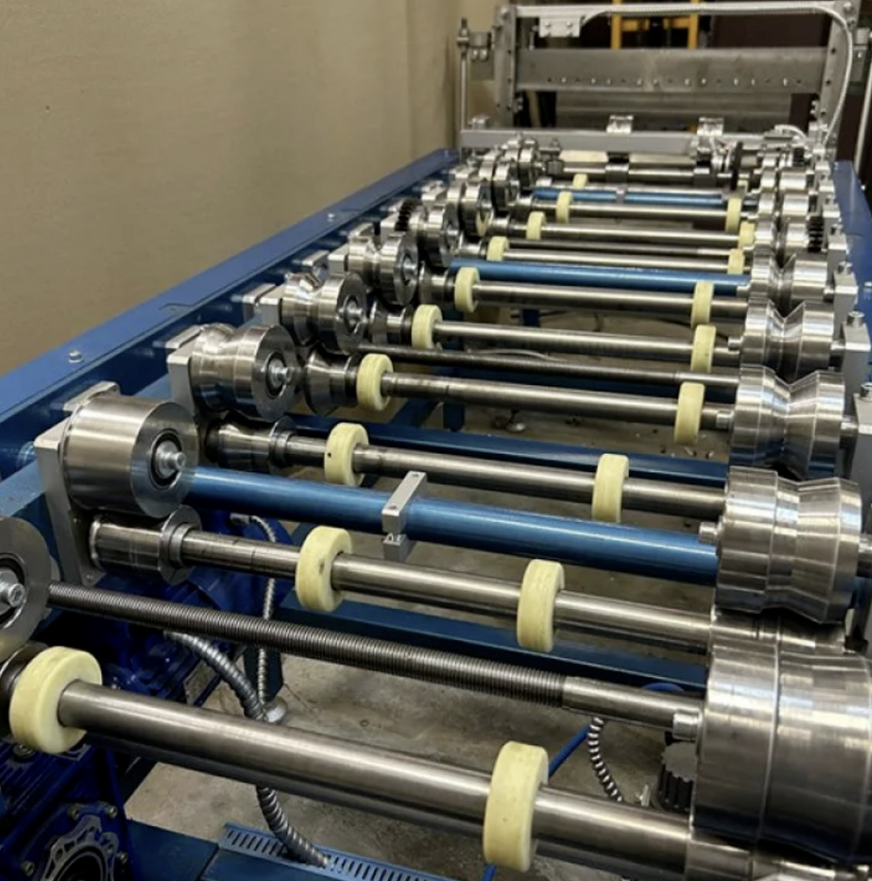

A Snap Lock Roofing Roll Forming Machine is specifically designed to manufacture these profiles efficiently, catering to the needs of the Nigerian market.

A Snap Lock Roofing Roll Forming Machine is an advanced piece of equipment designed to produce roofing panels with precision and speed. These machines are highly automated, ensuring consistent quality and reducing production costs.

Key Features:

This machine is ideal for manufacturers looking to meet the increasing demand for roofing solutions in Nigeria’s rapidly developing construction sector.

The Snap Lock Roofing Roll Forming Machine is perfect for producing roofing solutions for:

1. What are the benefits of using a snap lock roofing roll forming machine in Nigeria?

The machine allows manufacturers to produce durable, high-quality roofing panels with minimal waste, ensuring cost-effective production. Snap lock roofing panels are especially suitable for Nigeria's climate, as they provide excellent protection against rain and heat.

2. Can this machine handle Nigeria’s inconsistent power supply?

Yes, the machine can be equipped with voltage stabilizers and backup power options like generators to adapt to Nigeria's power conditions.

3. What materials are compatible with this machine?

The Snap Lock Roll Forming Machine can work with galvanized steel, aluminum, and pre-painted steel, making it versatile for various roofing needs.

4. How does the machine ensure accuracy?

The PLC control system, servo motors, and hydraulic cutting system ensure precision in both panel dimensions and cuts.

5. Is the machine customizable for Nigerian roofing standards?

Yes, the machine can be tailored to produce profiles that match Nigeria's standard roofing dimensions and styles.

6. What maintenance is required for this machine?

Routine maintenance includes checking lubrication levels, inspecting the rollers for wear, and ensuring the hydraulic system operates smoothly. With proper care, the machine can have a lifespan of 10+ years.

A Snap Lock Roofing Roll Forming Machine is a vital investment for Nigerian manufacturers aiming to cater to the country’s growing demand for high-quality roofing solutions. Its ability to produce durable, stylish, and efficient panels makes it indispensable in Nigeria’s booming construction industry.

Copyright 2026 © Machine Matcher.