To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

In cities like Dubai and Abu Dhabi, snap lock roofing is increasingly popular in contemporary constructions due to its sleek appearance and ability to withstand the region's intense heat and frequent sandstorms. This guide provides a detailed overview of the Snap Lock Roofing Roll Forming Machine, specifications, benefits, and answers to common questions about its application in the UAE.

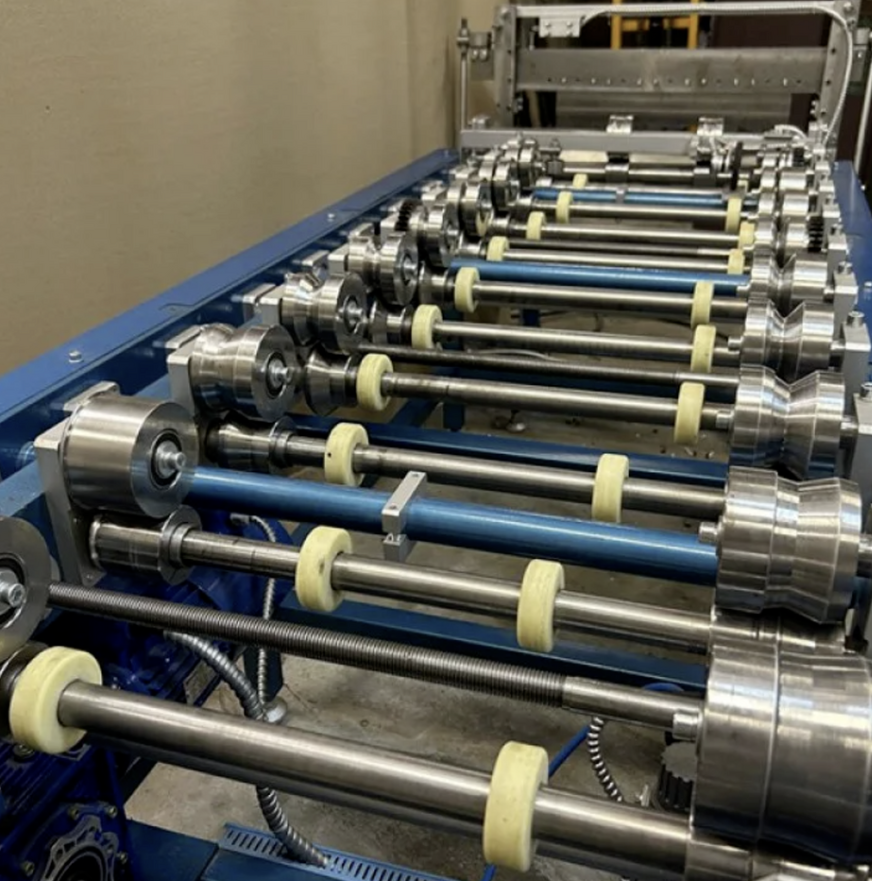

The Snap Lock Roofing Roll Forming Machine is a specialized equipment designed to produce high-quality snap lock roofing panels. These panels are widely used in modern architectural projects due to their interlocking design, which eliminates the need for additional fasteners, providing a clean and sophisticated look. The machine’s advanced technology ensures precise panel dimensions, making it ideal for the demanding conditions of the UAE.

Key Features:

Q1. What materials can the Snap Lock Roofing Roll Forming Machine process?

A1. The machine can process galvanized steel, aluminum, and zinc-coated sheets, which are commonly used in UAE construction due to their resistance to rust and corrosion.

Q2. Is the machine suitable for the UAE's power supply?

A2. Yes, the machine can be customized to operate on the UAE's standard power supply (380V, 50Hz, 3-phase).

Q3. How does the machine ensure panel durability?

A3. The machine uses precision rollers and hydraulic cutting systems, ensuring consistent quality and precise profiles that enhance panel durability.

Q4. Can it handle large-scale projects?

A4. Absolutely. The machine’s production speed and automation features make it suitable for large-scale projects like residential communities and commercial complexes in the UAE.

Q5. What are the setup and installation requirements?

A5. The machine requires a stable foundation, standard electrical connections, and a compressed air system for hydraulic operations. Installation services can be provided locally.

Q6. How is the machine maintained?

A6. Regular lubrication of moving parts, periodic cleaning of rollers, and inspection of the PLC system are recommended. Local service teams can assist with maintenance in the UAE.

The Snap Lock Roofing Roll Forming Machine is a game-changer for the UAE construction industry, providing high-quality roofing solutions tailored to withstand the region's extreme climate. Whether for a sleek urban skyscraper in Dubai or a luxurious villa in Abu Dhabi, this machine delivers unparalleled performance and aesthetics. Its advanced features, robust design, and suitability for large-scale projects make it an essential investment for manufacturers in the UAE.

Copyright 2026 © Machine Matcher.