To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Snap Lock roofing has become a popular choice in the UK, particularly in rural and suburban areas, due to its sleek appearance, durability, and ease of installation. This guide provides a comprehensive look at the Snap Lock Roofing Roll Forming Machine, its specifications, benefits, and FAQs to help buyers in the UK make an informed decision.

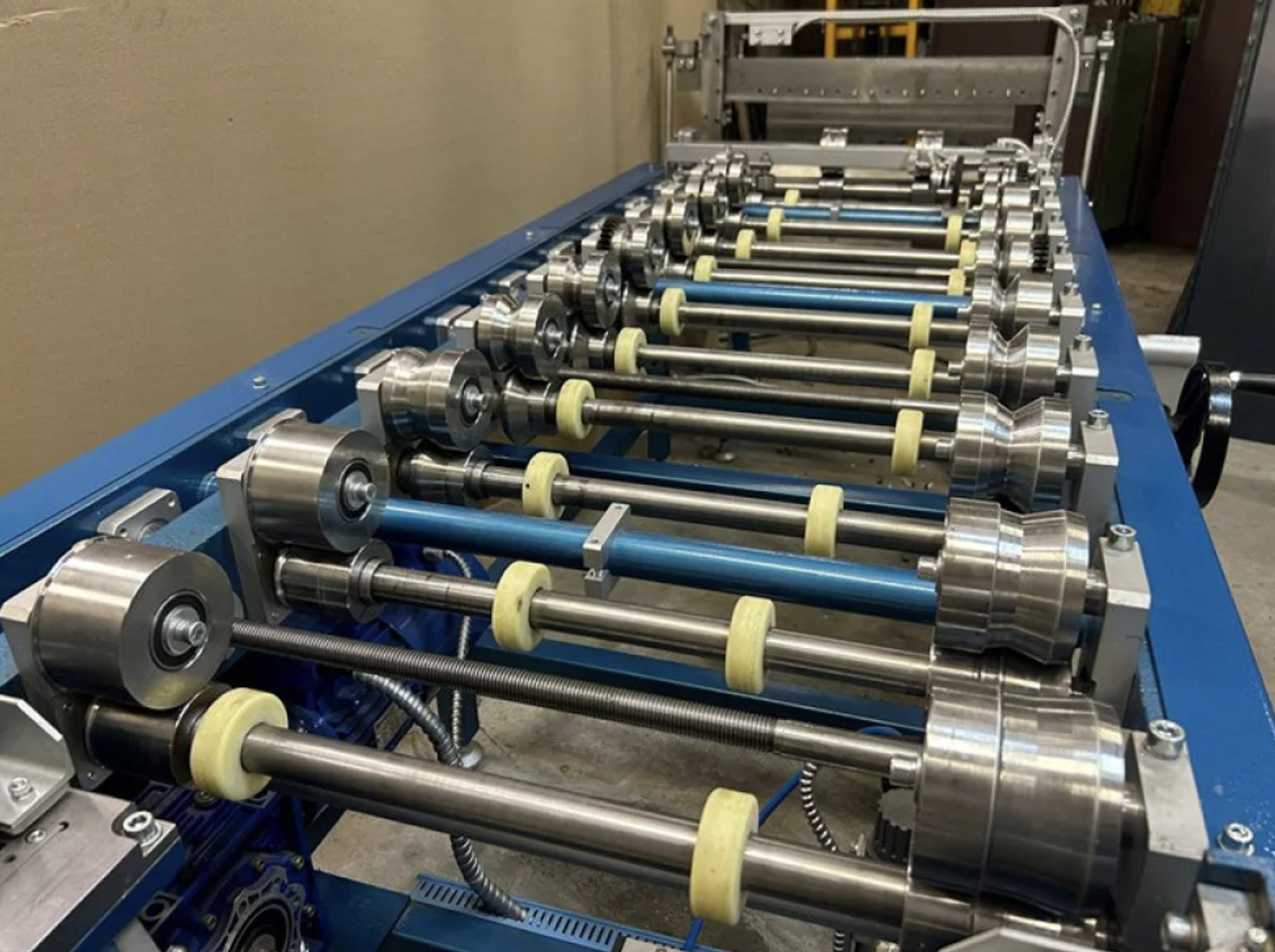

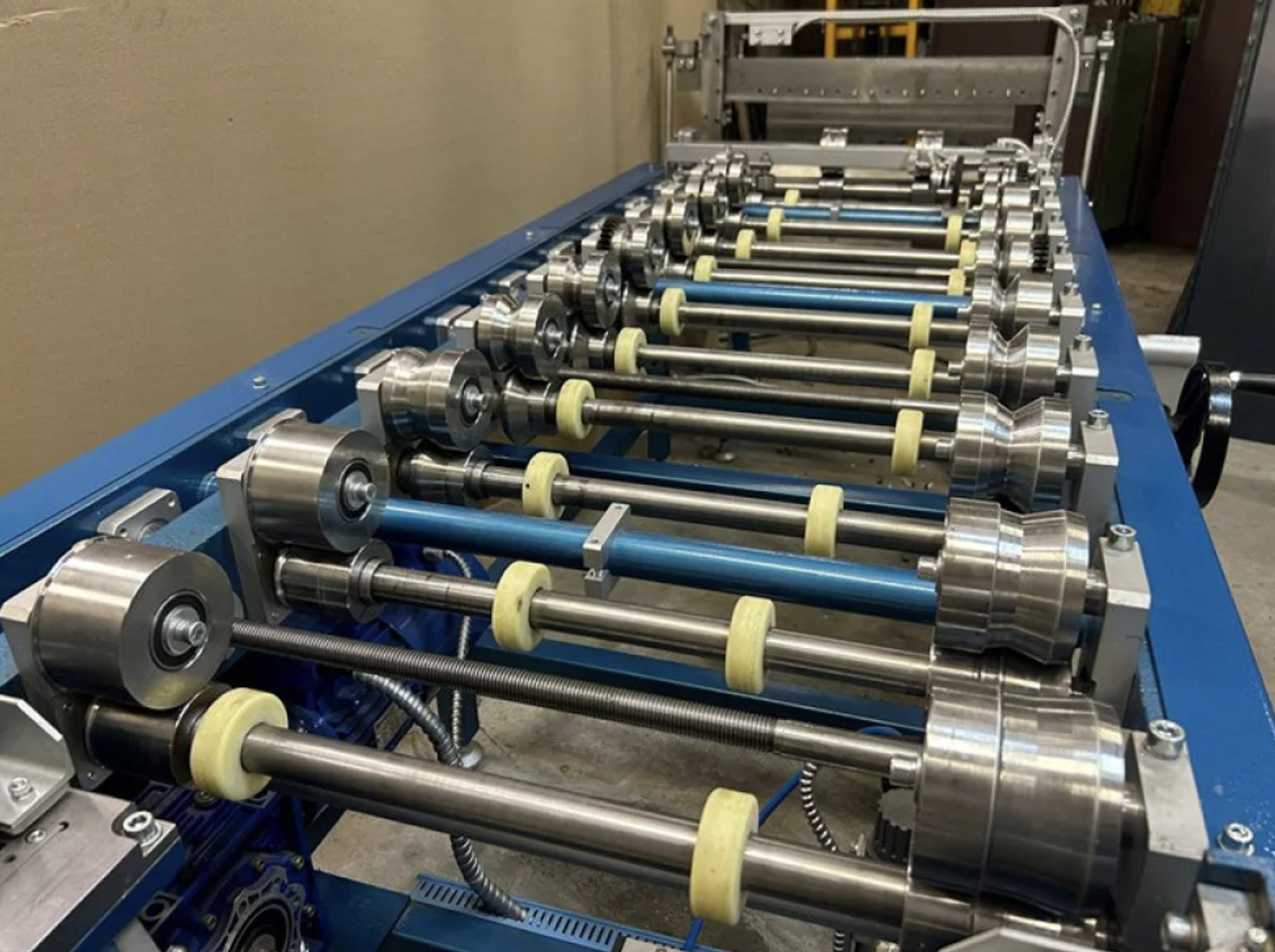

The Snap Lock Roofing Roll Forming Machine is designed to produce high-quality Snap Lock panels with precision and efficiency. These panels feature interlocking seams that snap together without requiring special tools or fasteners, making them ideal for residential, commercial, and agricultural buildings in the UK.

This machine is built for performance and longevity, ensuring consistent production while meeting the UK's construction standards.

Q1: What is the advantage of Snap Lock roofing over traditional standing seam roofing?

A1: Snap Lock roofing panels are easier to install as they snap together without requiring mechanical seaming tools. This makes them ideal for smaller or DIY projects, reducing installation time and costs.

Q2: Can this machine handle different materials used in the UK?

A2: Yes, the machine is designed to process a variety of materials, including galvanized steel, aluminum, and copper, commonly used in UK construction.

Q3: Is the machine energy-efficient?

A3: Absolutely. The high-efficiency motors and PLC system minimize energy consumption, aligning with the UK's focus on sustainable manufacturing.

Q4: Can this machine produce custom widths for UK-specific requirements?

A4: Yes, the machine can be customized to produce panels in specific widths to meet architectural and building code requirements in the UK.

Q5: What kind of maintenance is required?

A5: Regular lubrication, roller inspection, and periodic PLC updates are recommended to keep the machine running efficiently.

Q6: How does the machine ensure compliance with UK safety standards?

A6: The Snap Lock Roll Forming Machine is equipped with CE-certified safety features, including emergency stop buttons, full enclosures, and operator training manuals to ensure compliance with UK regulations.

Q7: What is the lead time for machine delivery to the UK?

A7: The standard lead time is 6–8 weeks, including shipping and customs clearance.

The Snap Lock Roofing Roll Forming Machine is an excellent investment for UK businesses seeking to produce high-quality, aesthetically pleasing roofing panels. Its precision engineering, ease of use, and adaptability to UK standards make it a valuable addition to any roll forming operation.

For further details or a personalized quote, please contact us at Machine Matcher, your trusted partner for roll forming machines worldwide.

Copyright 2026 © Machine Matcher.