To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

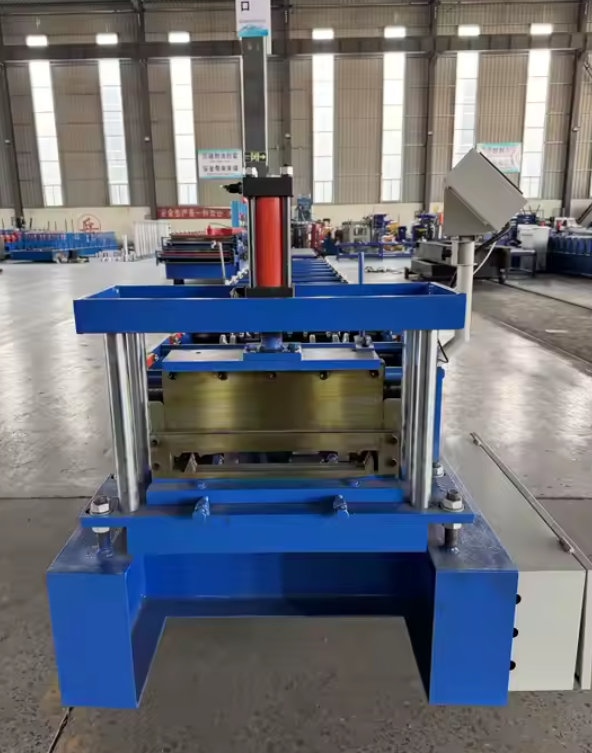

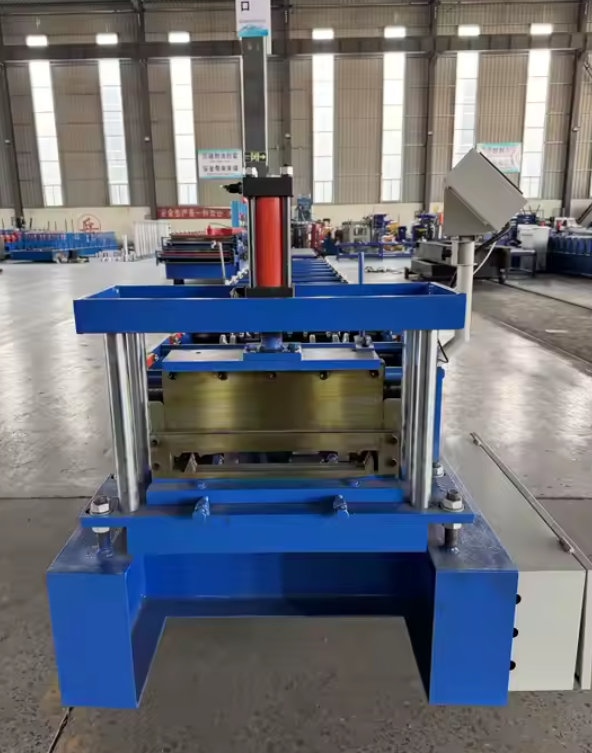

Delivering modern precision and durable quality, our Standing Seam Metal Roof Roll Forming Machine is engineered to meet the highest standards of metal roofing fabrication. Perfect for use across residential, commercial, and industrial roofing projects, this machine is a vital tool for contractors, metal building manufacturers, and specialty roofing companies throughout the UAE.

This standing seam roll forming machine is custom-built for your specific profile and production requirements. Whether you are in Abu Dhabi, Dubai, Sharjah, or any other location in the United Arab Emirates, we deliver powerful and efficient metal forming solutions directly from our trusted manufacturing partners.

All our machines are brand new, come with a one-year warranty, and include full technical support for maintenance and repairs.

Machine Type: Standing Seam Metal Roof Roll Forming Machine

Production Speed: 15–30 meters per minute (adjustable)

Material Thickness Range: 0.3 mm – 0.8 mm

Material Width Range: 300 mm – 600 mm

Material Types: Galvanized Steel (GI), Aluminum, Pre-painted Steel (PPGI), Zinc-Aluminum Alloy-Coated Steel

Material Yield Strength: Up to 550 MPa

Roller Material: High-grade GCr15 steel

Roller Surface Treatment: Hard Chrome Coated for corrosion resistance

Number of Forming Stations: 16–20 stations (customizable based on profile)

Roller Shaft Diameter: 70 mm

Shaft Material: High-tensile steel (solid, heat-treated)

Main Drive Type: Gearbox drive system

Power: 380V, 50Hz, 3 Phase (customized to UAE power supply standards)

Motor Power: 11 kW

Cutting Method: Hydraulic cutting after forming

Blade Material: Cr12MoV precision-ground, heat-treated

Control Type: Fully Automated PLC Control System

Operating Mode: Manual and Automatic modes available

De-coiling System: Manual or hydraulic uncoiler (optional automatic expansion)

Punching/Notching System: Optional hydraulic punching system

Machine Frame: Welded structural steel frame

Thickness of Frame Steel: 20 mm

Profile Shape: Customizable standing seam profiles (including Snap Lock and Mechanical Lock types)

Profile Width and Depth: Based on customer profile (typical seam height 25–50 mm)

Length Tolerance: ±1.5 mm for each 6 meters

Safety Features:

Full protective covers/guards around forming stations

Emergency stop buttons on key points of the machine

Overload protection system for motors and hydraulic units

This Standing Seam Metal Roof Roll Forming Machine is ideal for industries such as:

Residential and Commercial Roofing Contractors

Pre-engineered Metal Building Manufacturers

Industrial Roofing Projects

Architectural Cladding Systems

Government and Infrastructure Building Projects

Solar Energy Roof Structures

In the UAE’s fast-growing construction and infrastructure sector, standing seam metal roofing is increasingly popular for its strength, weather resistance, and aesthetic appeal. Our machine helps you produce high-quality panels with minimal labor and maximum reliability.

Location: Available for delivery anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, Ajman, Ras Al Khaimah, and other emirates.

Production: All machines are newly manufactured, customized for your specific standing seam profile and requirements.

Warranty: 1-year warranty from dispatch date.

Support: Long-term maintenance and repair support available.

Pricing: Based on customization and optional extras. Contact us for a tailored quote.

If you have profile drawings or special specifications, please email them to [email protected] for a detailed quotation.

Q1: Can this machine be customized for different standing seam profiles?

A: Yes. We build every machine based on your required profile drawings or samples. Snap Lock, Mechanical Lock, and Batten Cap types can all be manufactured.

Q2: What materials can the machine handle for the UAE climate?

A: It can process galvanized steel, aluminum, and pre-painted steel, all suited for the UAE’s hot and humid environment. Materials with high corrosion resistance are recommended.

Q3: How long does it take to receive the machine after ordering?

A: Typical production and delivery time ranges from 8–12 weeks depending on customization levels.

Q4: What is included with the machine delivery?

A: The machine comes fully assembled, tested, and packed for transport. A basic operation manual, spare parts list, and remote installation support are included.

Q5: Can the machine be upgraded later (e.g., automatic stacking, punching)?

A: Yes. We offer a range of optional extras such as automatic stackers, coil handling systems, hydraulic punching units, and upgraded control systems.

Q6: Is on-site installation and training available in the UAE?

A: Remote setup support is standard. If required, in-person installation and training services can be arranged at an additional cost.

Q7: What after-sales services are provided?

A: We offer troubleshooting support, spare parts, maintenance guidance, and, if needed, technician visits. Warranty covers parts replacement for manufacturing defects.

For more details or a tailored quote, email your profile drawing and project details to:

📧 [email protected]

Copyright 2026 © Machine Matcher.