To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

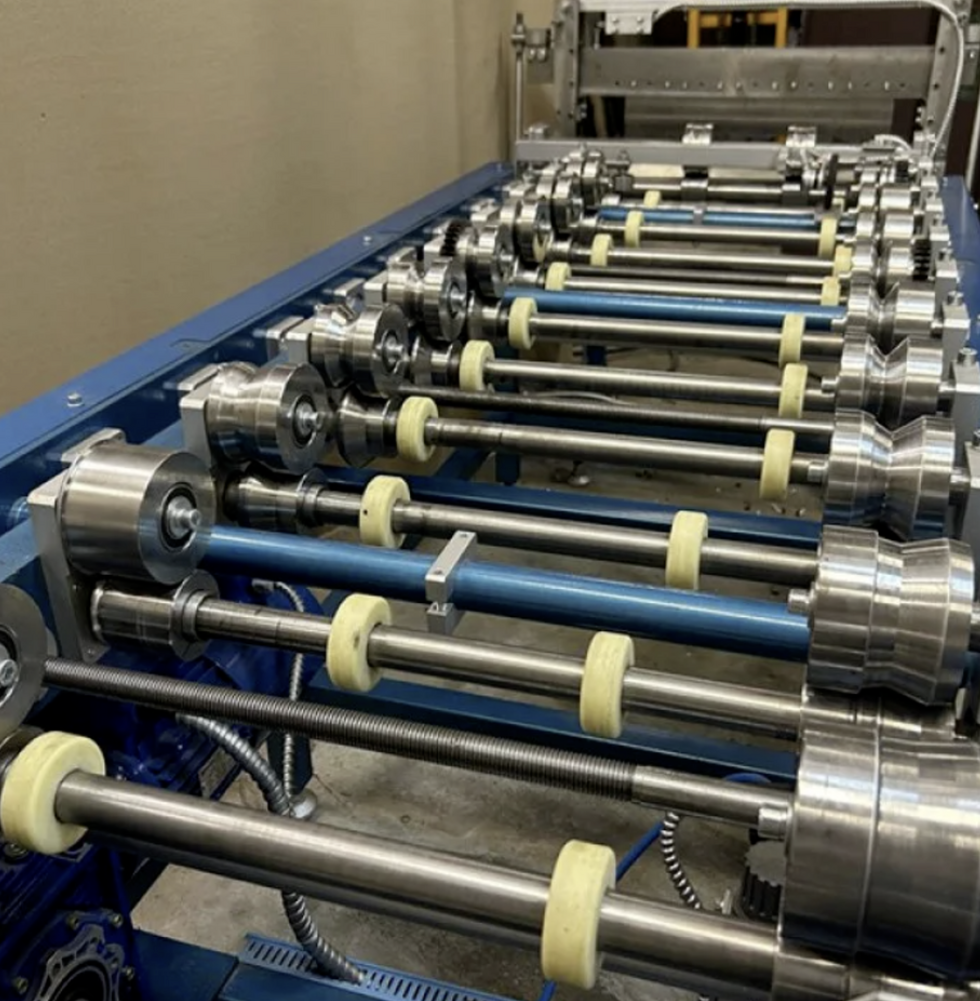

The standing seam roll forming machine operates by feeding metal coils into the machine, where they pass through a series of rollers that shape the metal into the desired standing seam profile. The machine includes various cutting, punching, and profiling components, ensuring high-quality and consistent panel production.

| Specification | Details |

|---|---|

| Roller Material | High-grade steel with chrome plating for durability and precision |

| Frame Size | Heavy-duty steel frame to minimize vibration and improve stability |

| Material Thickness | 0.4mm to 1.0mm |

| Material Width | 300mm - 600mm (adjustable based on requirements) |

| Cutting System | Hydraulic cutting system for smooth and burr-free cuts |

| Motor Power | 5kW to 10kW (varies based on machine size and requirements) |

| Control System | PLC control with touchscreen interface |

| Machine Speed | 15-30 meters per minute |

| Power Supply | Customized to Colombian standards (110V/220V/380V, 50Hz or 60Hz) |

| Safety Features | Enclosures, emergency stop buttons, and safety guards |

| Optional Features | Remote PLC control, automatic stacker, and coil handling systems |

Standing Seam Profile:

Q1: What materials can the standing seam roll forming machine handle?

A: It can process galvanized steel, aluminum, and pre-painted steel, commonly used in Colombia's roofing industry.

Q2: Is the machine suitable for Colombia's power supply?

A: Yes, the machine can be customized for Colombia's power standards, whether 110V, 220V, or 380V.

Q3: How fast can the machine produce panels?

A: The production speed ranges from 15 to 30 meters per minute, depending on material thickness and profile.

Q4: Are spare parts available locally in Colombia?

A: Many parts, such as cutters and rollers, are available globally and can be shipped to Colombia.

Q5: Does the machine support profile customization?

A: Yes, the machine can be adjusted to produce custom widths and profiles as per customer requirements.

Q6: What industries in Colombia commonly use standing seam panels?

A: Construction, agriculture, and commercial real estate sectors use these panels extensively for durable and weather-resistant roofing.

A standing seam roll forming machine is an essential investment for Colombian industries that demand high-quality and efficient roofing solutions. With customizable features and robust construction, these machines cater to the diverse needs of Colombia's construction market, ensuring long-term reliability and performance.

Copyright 2025 © Machine Matcher.