To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Steel deck roll forming machines are essential equipment in the construction and building industries, particularly in Canada, where steel decks are widely used for structural support in commercial, industrial, and residential buildings. These machines are designed to produce high-quality steel decking panels that offer superior strength, durability, and easy installation.

This guide covers everything you need to know about Steel Deck Roll Forming Machines in Canada, including machine specifications, how they work, and what to consider before buying one.

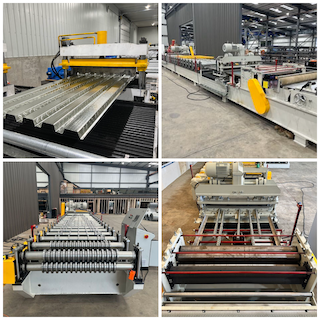

A steel deck roll forming machine is a specialized piece of equipment used to manufacture steel decking panels through a continuous roll forming process. These panels are commonly used for flooring systems, roofing applications, and structural frameworks in construction projects. The machine processes galvanized steel or other coated materials, forming them into precise profiles that meet industry standards.

Steel decking panels provide high strength-to-weight ratio, making them an ideal choice for construction projects that require durable and lightweight materials.

| Specification | Details |

|---|---|

| Material Thickness | 18g - 24g (1.2mm - 0.6mm) |

| Machine Weight | 20 tons |

| Machine Footprint | 85 feet |

| Main Power | 480V - 3 Phase - 60Hz |

| Motor Power | 32 HP |

| Gearbox Type | Chain Drive / Gearbox |

| Roll Forming Stations | 28 stations |

| Cutting System | Hydraulic Shear |

| Safety Features | Safety Covers (Optional), E-Stops |

Canada has a booming construction industry, with ongoing commercial, residential, and infrastructure projects requiring high-quality steel decking solutions. Steel decking is commonly used in:

Steel deck roll forming machines in Canada are built to comply with CSA (Canadian Standards Association) and ASTM (American Society for Testing and Materials) standards, ensuring that the produced panels meet local building codes and safety regulations.

In Canada, industrial machines typically operate on 480V, 3-phase, 60Hz power supply, which matches the power requirements of this roll forming machine, making it an ideal fit for Canadian manufacturers.

A: Steel deck roll forming machines are widely used in the construction, infrastructure, and commercial building industries in Canada. They produce steel decking panels for bridges, warehouses, high-rise buildings, and flooring applications.

A: The production speed depends on the material thickness and profile design, but typically, steel deck roll forming machines can produce 15-30 meters per minute.

A: Yes, the machine can be customized to produce various deck profiles based on project requirements. Multiple sets of rollers can be used to switch between different profiles.

A: Yes, the machine operates at 480V, 3-phase, 60Hz, which matches Canadian industrial power standards.

A: Regular maintenance includes:

A: Yes, training is recommended to ensure safe and efficient operation. Most manufacturers provide training sessions on how to operate and maintain the machine.

A: Yes, roll forming machine manufacturers offer delivery, installation, and after-sales support in Canada. It’s important to work with a supplier who provides on-site installation and operator training.

A Steel Deck Roll Forming Machine in Canada is an essential investment for manufacturers producing high-quality steel decking for the booming construction industry. With advanced roll forming technology, precision cutting, and high-speed production, these machines provide cost-effective solutions for Canadian steel fabricators.

Before purchasing, ensure that the machine meets your power requirements, profile specifications, and safety features. With the right machine, you can increase efficiency, reduce material waste, and meet Canadian building standards effectively.

If you need expert guidance or want a custom quote, contact Machine Matcher today for the best deals on new and used roll forming machines.

Copyright 2026 © Machine Matcher.