To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

|

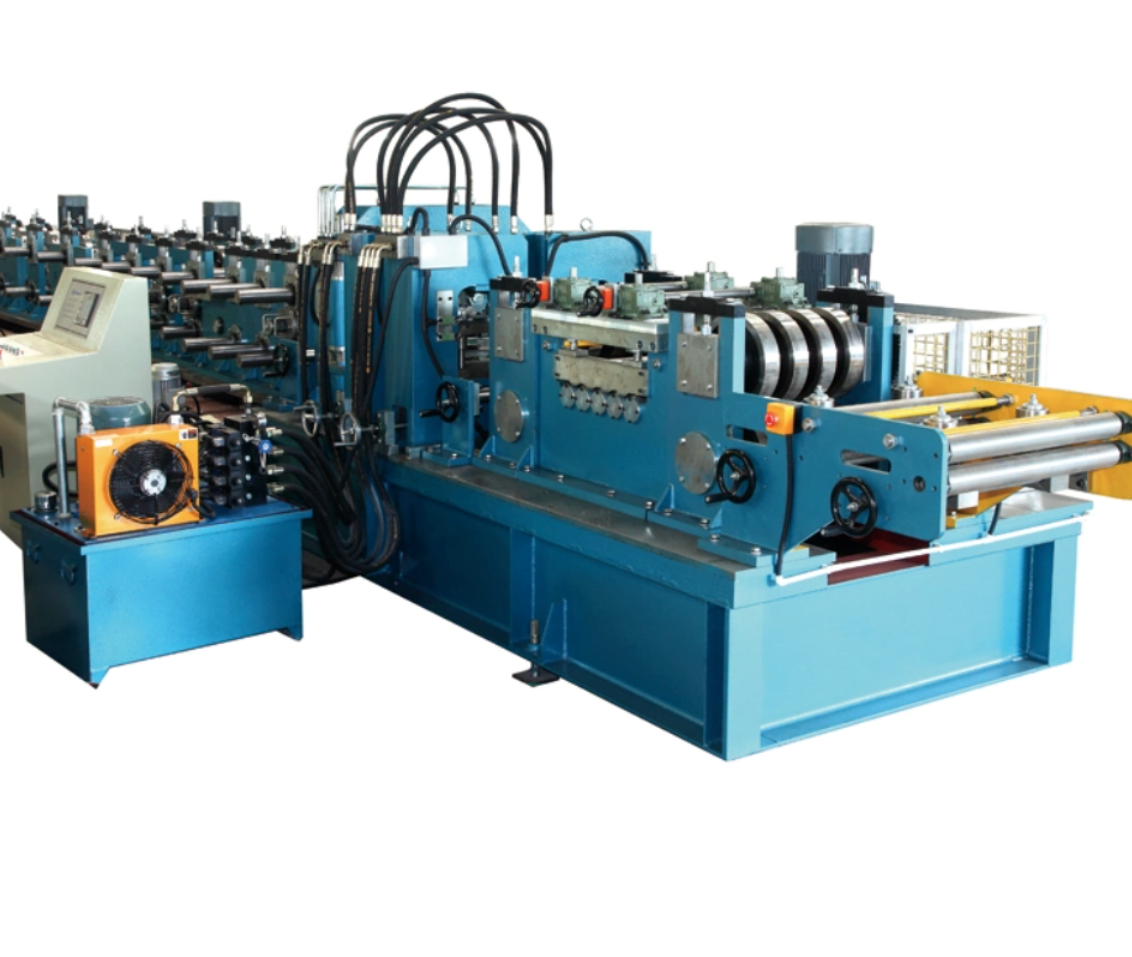

Material thickness |

1.5-3.0 or 2.0-4.0mm |

|

Suiting material |

Galvanized coils |

|

Main motor |

5.5kw*3 |

|

Shafts diameter |

82 or 90 mm |

|

Machine frame |

H450 |

|

Cutting material |

Cr12MOV.,Hardness 58-60HRC |

|

Forming rollers qty. |

15 stations |

|

Roller Material |

Cr12MOV.,Hardness 58-60HRC |

|

Wall thickness |

45mm |

Overview: A Steel Frame Roll Forming Machine is specifically designed to produce steel frames used in construction, including residential, commercial, and industrial buildings. These machines utilize a continuous process to convert flat steel coils into various frame profiles, ensuring efficiency and high precision in manufacturing.

Key Features:

Applications:

Advantages:

Conclusion: Investing in a Steel Frame Roll Forming Machine offers significant advantages in the construction industry, including enhanced production efficiency, cost savings, and flexibility in design. These machines are essential for manufacturers looking to meet the growing demand for steel framing solutions.

Copyright 2026 © Machine Matcher.