To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

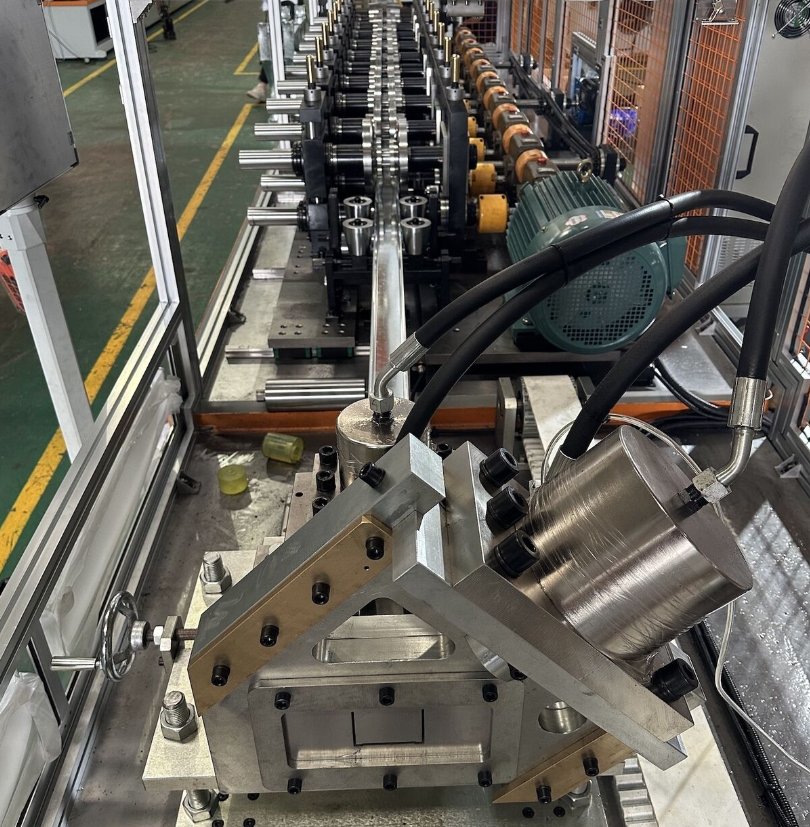

Steel stud roll forming machines are specialized equipment used to produce steel studs and tracks for construction projects. These machines are designed to deliver precision and efficiency, meeting the demands of Canada’s construction industry, particularly for commercial, residential, and industrial building applications.

A steel stud roll forming machine is engineered to fabricate steel studs and tracks from galvanized or stainless steel coils. These machines are highly efficient, automated, and customizable, making them essential for manufacturers in Canada seeking to produce high-quality framing components for drywall and partition systems.

| Feature | Specification |

|---|---|

| Material | Galvanized steel, stainless steel, aluminum |

| Material Thickness | 0.4 mm to 1.5 mm |

| Profile Width | 40 mm to 150 mm |

| Rollers Material | GCr15 steel with hard chrome plating |

| Frame | Welded steel with stress-relief annealing |

| Motor Power | 5 kW to 15 kW |

| Cutting System | Hydraulic cutting with servo control |

| Control System | PLC with touchscreen interface |

| Line Speed | 30-50 m/min |

| Dimensions | 6,000 mm x 1,200 mm x 1,500 mm |

| Weight | 4,500 kg to 7,000 kg |

| Extras | Automatic stackers, pre-punching systems, coil handling |

Q1: What is a steel stud roll forming machine used for?

A1: Steel stud roll forming machines are used to produce steel studs and tracks for framing in construction projects, including walls, ceilings, and partitions.

Q2: Can the machine produce different sizes of steel studs?

A2: Yes, the machine can be adjusted to produce various sizes and profiles to meet specific project requirements.

Q3: What materials can the machine handle?

A3: The machine primarily works with galvanized steel, stainless steel, and aluminum.

Q4: What is the typical production speed?

A4: Production speeds range from 30 to 50 meters per minute, depending on the material and profile size.

Q5: Is the machine suitable for the Canadian market?

A5: Absolutely. The machine complies with Canadian industry standards and is ideal for projects requiring high-quality steel framing components.

Q6: What should I consider when buying a steel stud roll forming machine in Canada?

A6: Consider the machine’s production capacity, customization options, material compatibility, and adherence to Canadian safety and quality standards.

Q7: Are there financing options for purchasing in Canada?

A7: Many suppliers offer financing options or leasing plans tailored to Canadian businesses. Check with local distributors or manufacturers for details.

Steel stud roll forming machines are indispensable for the Canadian construction industry, offering efficiency, precision, and adaptability. Investing in a reliable machine ensures compliance with local standards and supports the growing demand for sustainable and lightweight building materials. Whether you're setting up a new production line or upgrading existing equipment, these machines are a valuable asset for manufacturers in Canada.

Copyright 2026 © Machine Matcher.