To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

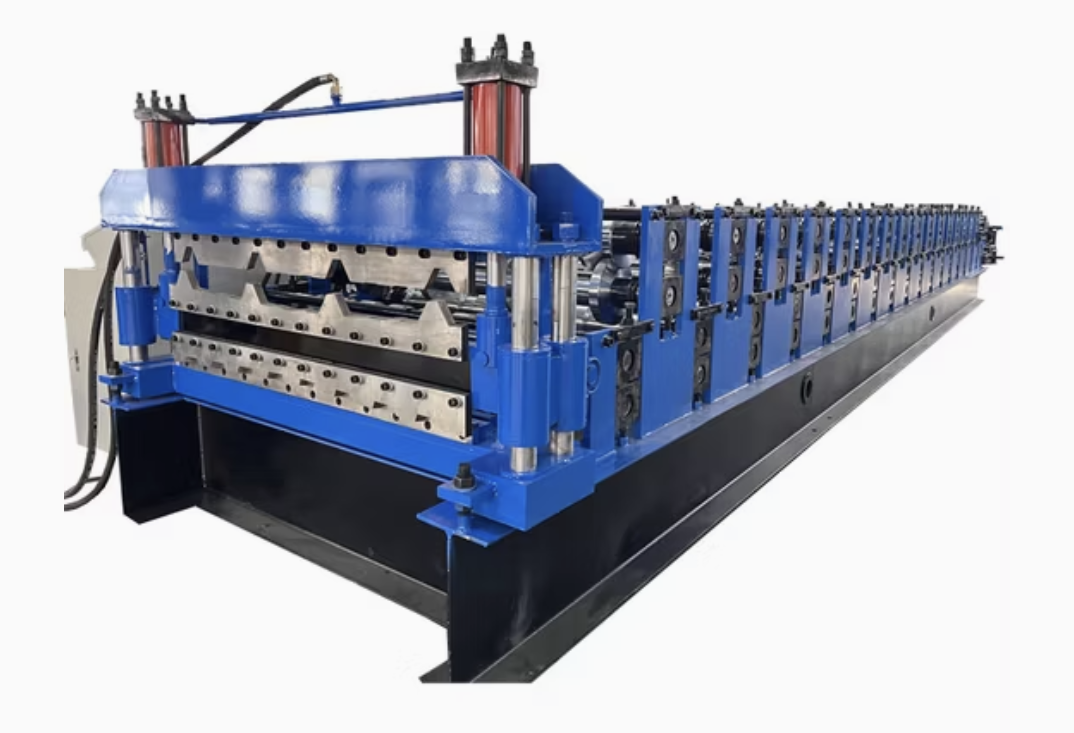

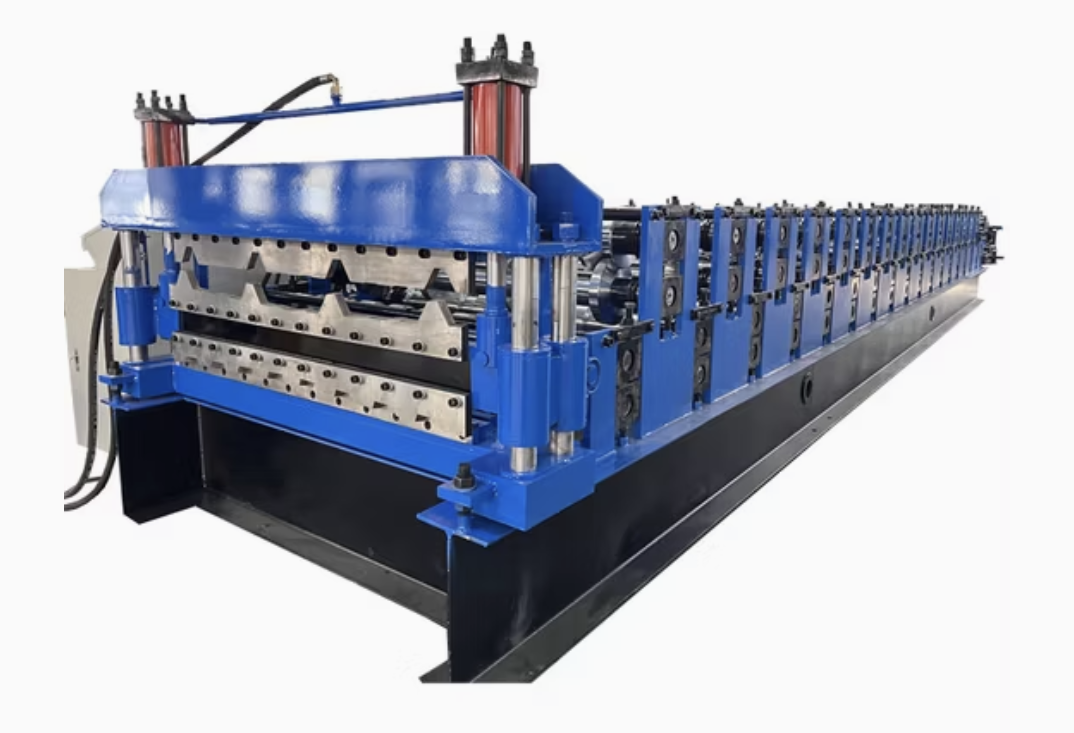

The Step Tile Roll Forming Machine is a specialized piece of equipment engineered to create metal roof tiles with a distinct step profile, widely used in residential and commercial roofing projects. Designed for durability and efficiency, this machine enables manufacturers to produce high-quality, precisely formed step tiles that mimic the appearance of traditional clay or stone tiles but with the lightweight advantages of metal. These tiles provide superior weather resistance and longevity, making them a preferred roofing solution across various regions and climates.

This roll forming machine typically processes materials such as galvanized steel, aluminum, or pre-painted steel, transforming flat metal coils into step-patterned tiles. The machine operates in a fully automated mode, controlled by a PLC (Programmable Logic Controller) system, ensuring consistent quality and speed throughout the production process.

Step Tile Roll Forming Machines require stable and level installation within a production facility. The machine typically comes with an installation guide, and some manufacturers provide on-site setup assistance. The installation generally involves connecting the machine to the power supply, configuring the PLC, and conducting a few trial runs to ensure smooth operation.

Routine maintenance is essential for the longevity and optimal performance of the Step Tile Roll Forming Machine. Key maintenance tasks include:

Q1: What materials can be used in a Step Tile Roll Forming Machine?

A1: The machine can process various metals like galvanized steel, aluminum, and pre-painted steel, typically within a thickness range of 0.3 mm - 0.6 mm.

Q2: How long does it take to form each tile?

A2: The forming speed averages around 8-12 meters per minute, which translates to quick production, but the exact time for each tile depends on the tile length and profile complexity.

Q3: Can the tile size and step height be adjusted?

A3: Yes, most Step Tile Roll Forming Machines allow for tile length adjustability and variable step heights, generally between 20 mm - 30 mm, enabling customization based on specific requirements.

Q4: Is there an option to emboss the tiles?

A4: Some models offer an embossing function, which adds texture to the tile surface, making it visually similar to traditional clay tiles. This feature may be available as an add-on or included in high-end models.

Q5: How complex is the installation process for this machine?

A5: Installation requires proper alignment and power connections. While the process is straightforward, it’s advisable to seek assistance from the manufacturer or a trained technician for optimal setup and calibration.

Q6: What safety features does this machine have?

A6: Safety features typically include an emergency stop button, overload protection, and protective guards around moving parts to ensure operator safety.

Q7: How often should I perform maintenance on the machine?

A7: Regular maintenance is essential for smooth operation. Key tasks like roller cleaning and lubrication should be done weekly, while the hydraulic system and PLC checks can be performed monthly.

Q8: Is this machine compatible with other roof tile profiles?

A8: The Step Tile Roll Forming Machine is specialized for step tile profiles, but some models may be versatile enough to accommodate minor adjustments. If multiple profiles are needed, consider consulting the manufacturer.

Copyright 2026 © Machine Matcher.