To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

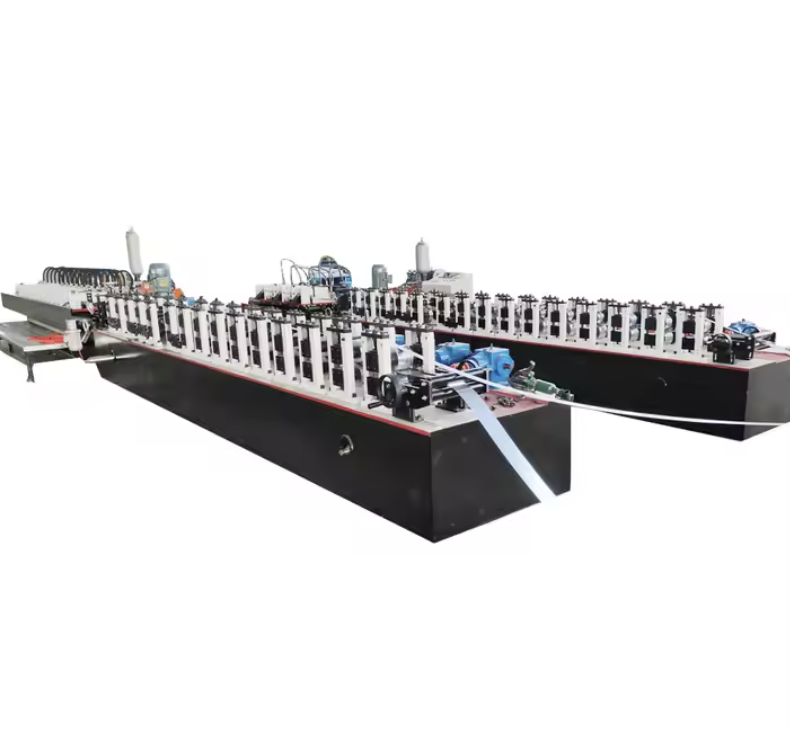

T-Bar Ceiling Grid Roll Forming Machine - United Arab Emirates

The T-Bar Ceiling Grid Roll Forming Machine is a specialized industrial machine designed for the production of T-bar ceiling grid systems. These grids are essential components in modern suspended ceiling installations, widely used in commercial and residential buildings, office spaces, retail outlets, and industrial facilities. This machine ensures high precision, efficiency, and ease of operation, making it an ideal choice for manufacturers and construction material suppliers in the United Arab Emirates (UAE) and the wider Middle Eastern market.

The T-Bar ceiling grid system is extensively used in various industries, including:

All machines are new and custom-built to meet customer-specific profile and machine requirements. The T-Bar Ceiling Grid Roll Forming Machine will be shipped directly to the customer's location in the UAE from our trusted manufacturing partner. Pricing depends on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

Machine Matcher is a leading supplier of roll forming machines worldwide. We offer a wide range of industrial equipment, including:

We provide a full suite of services, including machine sales, maintenance, repair, setup, and adjustment for the roll forming industry.

If you have profile drawings or specific details to help us provide the best quote, please email all details to [email protected].

We supply roll forming machines to a diverse range of industries across Europe, the Middle East, North and South America, Africa, and Asia.

The production speed varies based on the profile design and raw material thickness but generally ranges from 10 to 30 meters per minute.

Yes, all machines are custom-built to meet customer requirements, including different profile shapes and dimensions.

This machine is compatible with Steel, GI (Galvanized Steel), and PPGI (Pre-Painted Galvanized Steel).

The lead time depends on the level of customization but typically ranges from 45 to 90 days including manufacturing, testing, and shipping.

Yes, on-site training is available, and we provide video instructions and remote support as well.

Contact us with your profile drawings and specifications at [email protected], and we will provide a customized quote.

We offer installation support, maintenance, spare parts supply, and repair services, with engineers available for overseas servicing.

For further inquiries, feel free to reach out via email or visit our website!

Copyright 2026 © Machine Matcher.