To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Supplied exclusively by Machine Matcher

Machine Matcher proudly offers the T Profile Roll Forming Machine, custom-built and optimized for industrial operations across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and all other emirates. This high-performance machine is engineered for precision, speed, and versatility in forming T-shaped metal profiles from steel and other materials. It is ideal for manufacturers seeking robust production output with minimized downtime and superior profile quality.

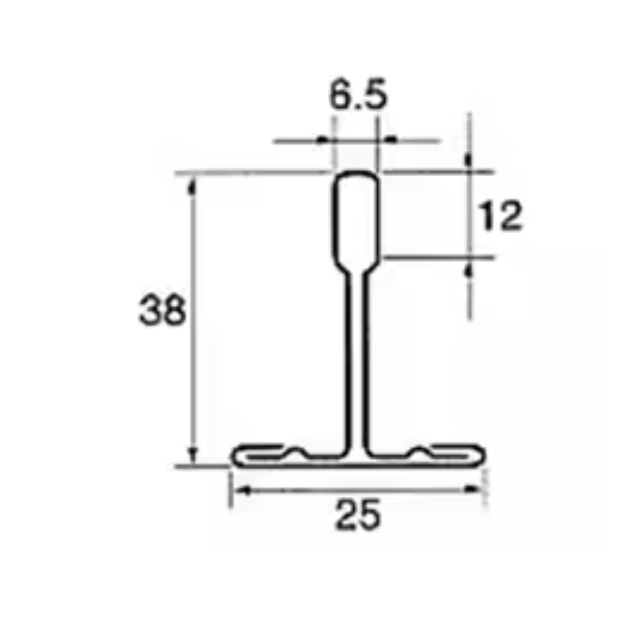

The T Profile Roll Forming Machine is designed to produce T-shaped metal profiles used in framing, ceiling grids, partitions, and structural reinforcements. With precise control systems and high-strength roller configurations, this machine guarantees excellent product consistency, even at high speeds.

Available exclusively from Machine Matcher, each machine is custom-built to suit your specific profile and material requirements, with support for varying widths, gauges, and profile depths. Whether you're manufacturing lightweight interior structures or load-bearing steel frameworks, this system delivers performance that aligns with your operational goals.

Machine Type: T Profile Roll Forming Machine

Production Speed: Up to 15–30 meters/min (adjustable)

Material Thickness Range: 0.3–1.2 mm

Material Width Range: 80–300 mm

Material Types: Galvanized steel, cold-rolled steel, stainless steel, aluminum

Material Yield Strength: Up to 350 MPa (50 ksi)

Roller Material: High-grade steel with heat treatment

Roller Surface Treatment: Chrome-plated for anti-rust and extended life

Number of Forming Stations: 12–18 stations (customizable based on profile)

Roller Shaft Diameter: 50 mm

Shaft Material: High-strength 45# steel, precision-ground

Main Drive Type: Chain or gearbox drive (customizable)

Motor Power: 5.5–11 kW (depending on machine configuration)

Power (for UAE): 380V, 50Hz, 3 Phase

Cutting Method: Hydraulic or flying cut-off system

Blade Material: Cr12Mov (heat-treated for extended lifespan)

Control Type: PLC automatic control system with touch screen interface

Operating Mode: Fully automatic with manual override option

De-coiling System: Manual or hydraulic de-coiler (capacity 3–5 tons)

Punching/Notching System: Optional – integrated hydraulic system

Machine Frame: Welded steel frame

Thickness of Frame Steel: 18–25 mm

Profile Shape: T profile

Profile Width and Depth: Width 20–60 mm / Depth 10–30 mm (customizable)

Length Tolerance: ±1 mm

Safety Features:

Protective covers/guards

Emergency stop button

Overload protection system

Remote Installation Support: Yes, we offer remote video guidance. On-site installation is available upon request.

This machine is utilized in a wide range of industries where light and medium-duty steel profiles are in demand:

Construction & Infrastructure

T profiles for framing, support systems, and drop ceilings.

Interior Fit-Out & Partitioning

Used in ceiling grids, wall framing, and modular room installations.

HVAC & MEP Contractors

For supporting ductwork and mechanical installations.

Logistics & Storage

Frame structures in racking systems and warehouse installations.

Steel Fabrication Companies

Volume production of consistent profile shapes for resale or in-house use.

Suspended ceilings

Metal framework systems

Drywall and partition support

Decorative structural profiles

Modular framing systems

Profile design (width, depth, thickness)

Additional punching and notching units

Motor and drive enhancements

Length and output speed tuning

Touch screen interface language

Custom roller designs for unique profile shapes

Q: Can the machine be customized for our profile?

A: Yes. Each machine is built to your specifications. Send your profile drawing to [email protected] for a detailed quote.

Q: What type of materials are used with this machine?

A: The machine is optimized for galvanized steel, aluminum, and cold-rolled steel with thickness from 0.3 mm to 1.2 mm and yield strength up to 350 MPa (50 ksi).

Q: Is remote support available?

A: Yes. We offer full remote installation support via video. On-site installation in the UAE is available on request.

Q: What is the lead time for manufacturing and shipping?

A: Standard production time is 30–60 days. Shipping time depends on your port location in the UAE.

Q: Is the machine ready to use once delivered?

A: Yes. Once installed and connected to power, it is ready for operation after initial calibration.

Prices start from: USD 38,000 (standard configuration)

What affects the final price:

Profile complexity

Automation level

Punching/notching options

Custom electrical components or drives

Special coatings or materials

All machines are new and built-to-order, delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and beyond.

✅ Custom-Built Profiles: Machines are tailored precisely to your dimensions and requirements.

✅ Heavy-Duty Frame Construction: Built for UAE climates and demanding operational conditions.

✅ High-Performance Output: Efficient roll forming with consistent quality across every batch.

✅ After-Sales Support: One-year warranty with remote diagnostics and spare part availability.

✅ Expertise You Can Trust: Machine Matcher provides technical guidance and support before, during, and after installation.

✅ Flexible Configurations: Available with punching, notching, and flying shear options for increased productivity.

Cost Savings: Faster production cycles, reduced material waste, and minimal maintenance downtime lead to greater ROI over time. Compared to imported standard machines, our T Profile machines offer superior adaptability and performance.

All machines are covered by a 1-year warranty from dispatch date, with durable service life, reliable operation, and spare part availability. Machine Matcher also provides ongoing maintenance and repair support.

To get the most accurate quote for your T Profile Roll Forming Machine, please send your profile drawings, material details, and any additional requirements to:

A technical advisor from Machine Matcher will follow up with a tailored proposal based on your production needs.

Copyright 2026 © Machine Matcher.