To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

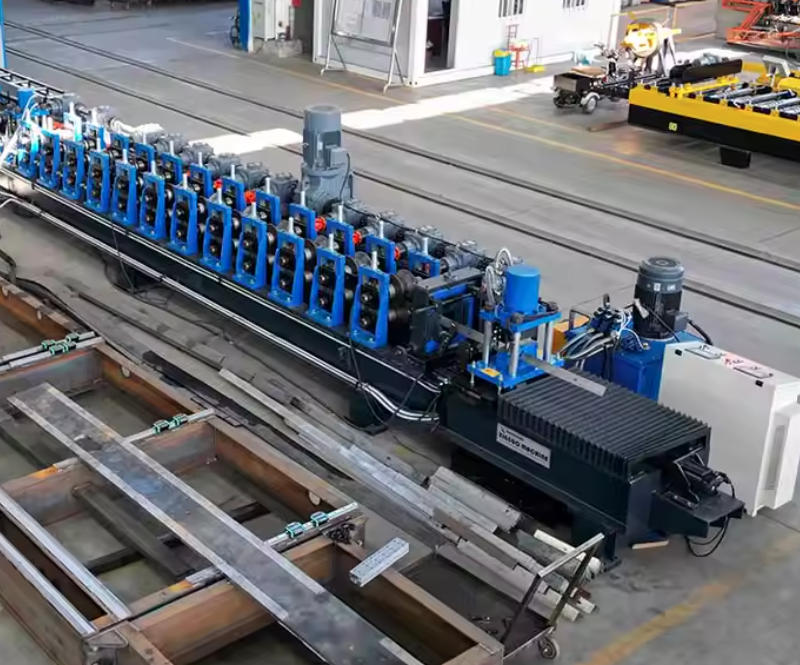

Triangle Angle Bead Channel Roll Forming Machine – Available in the UAE

Machine Matcher proudly offers the Triangle Angle Bead Channel Roll Forming Machine, engineered for precision and efficiency in producing high-quality angle bead profiles. This machine is tailored to meet the demands of the construction and interior finishing industries across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

This machine caters to various industries, including:

Construction: For creating angle beads used in reinforcing drywall corners.

Interior Finishing: Producing profiles for aesthetic and protective purposes in interiors.

Metal Fabrication: Manufacturing custom metal profiles for diverse applications.

Utilization Examples:

Producing angle beads for drywall installations.

Creating custom metal profiles for architectural designs.

Machine Type: Triangle Angle Bead Channel Roll Forming Machine

Production Speed: 15–25 meters per minute (adjustable)

Material Thickness Range: 0.3 mm to 1.0 mm

Material Width Range: 50 mm to 200 mm

Material Types: Galvanized steel, aluminum, stainless steel

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 steel with hard chrome plating

Roller Surface Treatment: Hard chrome plating

Number of Forming Stations: 12–20 stations (depending on profile complexity)

Roller Shaft Diameter: 60 mm

Shaft Material: 45# steel with tempering

Main Drive Type: Chain or gear drive

Power: Customized to UAE standards (e.g., 380V/50Hz)

Motor Power: 7.5 kW to 11 kW

Cutting Method: Hydraulic cutting or servo motor-controlled cutting

Blade Material: Cr12MOV steel, heat-treated

Control Type: PLC (Programmable Logic Controller) with touch screen

Operating Mode: Automatic

De-coiling System: Manual or hydraulic (5-ton or 10-ton capacity)

Punching/Notching System: Optional in-line punching or perforation dies

Machine Frame: Heavy-duty steel frame

Thickness of Frame Steel: 18 mm

Profile Shape: Triangle angle bead

Profile Width and Depth: Customizable as per requirements

Length Tolerance: ±0.5 mm

Safety Features:

Protective covers/guards

Emergency stop button

Overload protection system

Q: Can the machine be customized for our profile?

A: Yes, Machine Matcher offers customization to match your specific profile requirements.

Q: Is remote installation support available?

A: Yes, we provide remote video guidance, and on-site installation is available upon request.

Q: What is the lead time for manufacturing and shipping?

A: Production typically takes 30–60 days, and shipping time depends on the destination port.

Q: What type of material is normally used with this type of machine, and what are the material gauge and ksi?

A: Common materials include galvanized steel, aluminum, and stainless steel, with thickness ranging from 0.3 mm to 1.0 mm and yield strength up to 550 MPa.

Prices start from: $30,000 USD

What affects the final price: Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

All machines are new and custom-built to meet customers' specific profile and machine requirements. This machine can be delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah, directly from our manufacturing partner.

Customization: Tailored to meet specific profile requirements.

Efficiency: High production speed with precise cutting.

Durability: Robust construction ensures long-term reliability.

Support: Comprehensive after-sales service and technical support.

How these benefits translate to cost savings or improved output:

Reduced Downtime: Reliable performance minimizes production interruptions.

Lower Maintenance Costs: Durable components reduce the need for frequent repairs.

Increased Productivity: High-speed operation boosts output.

Profile Dimensions: Adjustable to meet specific design requirements.

Material Compatibility: Configured to handle various materials and thicknesses.

Additional Features: Optional punching, notching, and stacking systems.

All machines are covered by a one-year warranty from the date of dispatch, along with durable maintenance and repair support.

For inquiries or to receive a tailored quote, please email your profile drawings or any other relevant information to [email protected].

All machines described are supplied exclusively by Machine Matcher.

Copyright 2026 © Machine Matcher.