To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

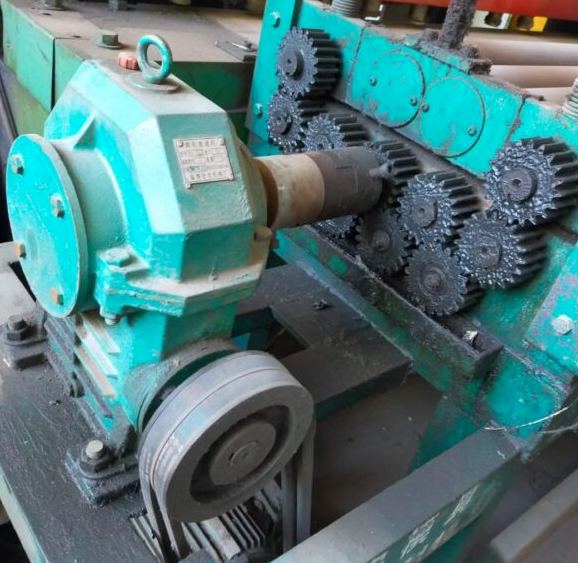

The Used VIGERT Cutting Line CL316 is a high-performance industrial cutting system engineered to process sheet metal coils with precision, speed, and reliability. Designed for heavy-duty environments, this machine is ideal for manufacturers seeking a dependable solution for coil processing across a range of materials, including steel, stainless steel, and aluminum. With a robust construction and an intelligent control system, it provides both versatility and productivity, making it a valuable asset for metalworking operations in diverse industries such as automotive, construction, HVAC, and general manufacturing.

Whether you’re producing components that require tight tolerances or managing large-scale coil cutting operations, the CL316 is built to deliver consistent results while minimizing material waste and downtime.

The “3×1600” designation refers to the machine’s cutting capacity:

Maximum Thickness: 3 mm

Maximum Coil Width: 1600 mm

This allows the CL316 to handle a wide range of sheet metal coils with varying sizes and thicknesses, offering flexibility to accommodate different customer requirements and material types. It is especially useful for operations that process medium to heavy gauge material on a regular basis.

Manufactured with durability in mind, the Used VIGERT Cutting Line CL316 is constructed from high-grade components that can withstand continuous operation under demanding industrial conditions. The frame and structural elements are designed to handle the mechanical stresses of coil handling, leveling, and cutting, ensuring long-term stability and reduced maintenance needs.

This machine is suitable for both high-throughput production lines and smaller batch operations where reliability is essential.

A critical component of this cutting line is its automated coil feeding system, which ensures a steady and uninterrupted flow of sheet metal into the cutting section. By automating this process, the system:

Reduces manual handling

Improves safety

Increases overall productivity

Minimizes coil feeding errors

This feature is especially beneficial in high-volume operations where speed and consistency are crucial to meeting delivery deadlines.

The cutting unit is equipped with precision-engineered blades and mechanisms that guarantee clean, accurate cuts every time. This high level of accuracy is vital for producing finished sheet sizes that meet strict dimensional requirements, especially in industries where quality and consistency are paramount.

The CL316 enables manufacturers to achieve tight tolerances with minimal rework, reducing scrap and enhancing product quality.

Before cutting, it’s essential that sheet metal is flat and defect-free. The CL316 features an integrated straightening and leveling mechanism that prepares the coil material for cutting by removing imperfections such as coil set, camber, or crossbow. This step:

Improves the quality of the final product

Prevents warping during cutting

Reduces material waste

Ensures better stacking and handling downstream

This feature is especially important when working with thicker gauges or coils that have been in storage and may have developed irregularities.

The cutting line is operated via a user-friendly control panel, which allows operators to:

Set cutting dimensions

Program multiple cut lengths

Monitor real-time production data

Adjust parameters on-the-fly

Store and recall cutting programs

This level of automation enhances efficiency and helps reduce setup times between jobs. It also improves accuracy and repeatability, especially in multi-batch operations.

The system’s interface is designed to be intuitive, reducing the training time required for new operators and increasing uptime.

The Used VIGERT Cutting Line CL316 supports a wide range of materials, including:

Mild steel

Galvanized steel

Aluminum

Stainless steel

This versatility makes it suitable for various applications, such as:

Roofing and cladding panel production

HVAC ducting

Metal furniture

Electrical enclosures

Structural components

Its ability to process different materials with varying gauges ensures the machine can be integrated into many production lines without needing significant modifications.

Max Coil Thickness: 3.0 mm

Max Coil Width: 1600 mm

Construction: Industrial heavy-duty frame and structure

Material Compatibility: Steel, stainless steel, aluminum

Key Systems: Coil feeding, straightening/leveling, cutting

Controls: Touchscreen PLC system with programmable settings

Condition: Used – Excellent operational status

Location: China

Depending on the location and chosen delivery method, the shipping timeline for the Used VIGERT Cutting Line CL316 is as follows:

Air Freight: Approximately 7–10 days

Sea Freight: Typically 30–45 days for most international destinations

We recommend discussing delivery options based on your project timeline and budget. Our team can assist you with logistics and customs clearance documentation if needed.

Cost-effective: As a high-performance used machine, it offers significant savings compared to new equipment while maintaining excellent cutting performance.

Industrial reliability: Designed to meet the needs of continuous production environments.

Ready-to-ship: The machine is located in China and can be prepared for dispatch promptly.

Global Support: We offer assistance with sourcing spare parts, technical questions, and inspections.

Q: What kind of materials can the CL316 handle?

A: The machine is capable of processing steel, stainless steel, and aluminum coils with a thickness of up to 3 mm and width of up to 1600 mm.

Q: Is this machine suitable for high-volume production?

A: Yes. With automated coil feeding, leveling, and precision cutting, the CL316 is built for industrial-scale operations that require consistency and speed.

Q: Can I inspect the machine before buying?

A: Yes. We can arrange an inspection either virtually or in-person, depending on your location and availability.

Q: Does the machine come with training or support?

A: While the machine is sold used, our team can assist you with operational guidance, installation coordination, and supplier contacts for any parts or service needs.

Q: Can the machine be integrated into an existing production line?

A: Absolutely. The CL316’s design and programmable control system make it compatible with a variety of production environments. We can help assess compatibility with your current setup.

Q: What kind of maintenance is required?

A: Like any industrial cutting line, regular maintenance such as lubrication, blade inspections, and software checks is recommended. We can provide a basic maintenance checklist upon request.

Q: How soon can the machine be delivered?

A: Delivery by air takes approximately 7–10 days, while shipping by sea typically takes 30–45 days depending on your location.

If you are looking for a specific machine or want more details about the Used VIGERT Cutting Line CL316, get in touch with our team. We specialize in sourcing machines globally and can help you find the right solution for your production needs.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

We’re ready to help you match with the right machine, whether you’re looking to expand your operations or improve production efficiency.

Copyright 2026 © Machine Matcher.