To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

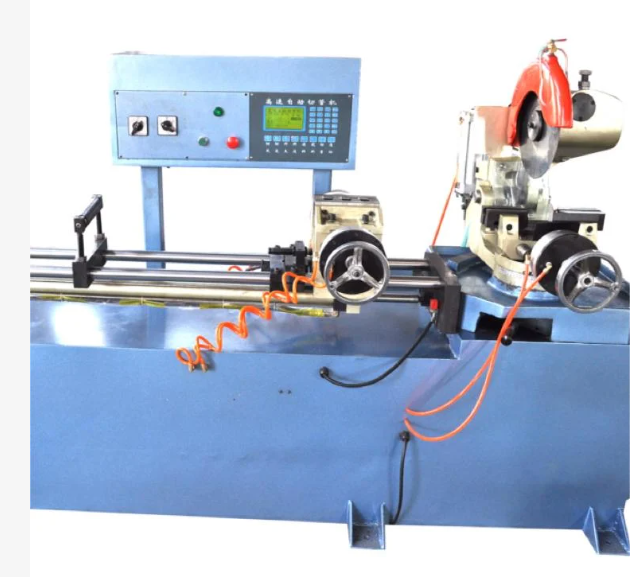

Brand: VIGERT

Condition: 100% New

Model: MC-315CNC

Manufacturing Year: 2024

Function: Pipe Cutting

Location: China

The VIGERT MC-315CNC Pipe Cutting Machine is a cutting-edge industrial solution engineered for the automated, high-precision cutting of a wide variety of pipe materials. Manufactured in 2024 and equipped with the latest CNC technology, this machine offers advanced capabilities for both standard and complex pipe cutting tasks across multiple industries.

Designed for manufacturers and fabricators who demand consistent results, high efficiency, and robust construction, the MC-315CNC brings together quality engineering and modern automation to meet today’s production standards.

Whether you are working in metal fabrication, plumbing systems, automotive production, construction, or any application involving round or shaped pipes, the VIGERT MC-315CNC is built to handle the workload with accuracy and reliability.

At the heart of the MC-315CNC is its computer numerical control (CNC) system, which allows for complete control of the cutting process. Operators can input exact cutting parameters such as:

Pipe length

Cut angle

Cutting speed

Repetition and pattern programming

This programmable logic ensures repeatable, consistent, and accurate cuts, drastically reducing human error and manual rework. Whether cutting a single piece or running batch jobs, the CNC control allows the machine to maintain precision across all operations.

Accuracy is a critical requirement for pipe cutting, especially in applications involving pressure systems or precision assemblies. The MC-315CNC is designed for clean and burr-free cuts, with precise dimensional tolerances. This precision significantly enhances the quality and functionality of the final product, reducing post-processing and improving the fit and function of fabricated assemblies.

One of the strengths of the MC-315CNC is its ability to work with a wide range of pipe materials. These include:

Carbon steel

Stainless steel

Aluminum

Copper

Brass

Plastic and PVC

This broad material compatibility makes the machine highly adaptable across various sectors, from light-duty workshop needs to heavy-duty industrial production lines. The machine is also capable of cutting different pipe diameters and wall thicknesses, offering flexibility for different project requirements.

The fully automated operation made possible by the CNC system allows for hands-off cutting. Once the pipe is loaded and the program is initiated, the machine performs cuts autonomously, which increases output and allows operators to manage multiple tasks simultaneously.

This automation translates into:

Reduced labor costs

Shorter production cycles

Minimal operator fatigue

Greater safety through reduced manual intervention

Industrial settings demand reliability and durability. The VIGERT MC-315CNC is constructed from heavy-duty steel, ensuring it can endure continuous operation under challenging conditions. Its components are precision-machined and tested to meet international standards for longevity and operational performance.

The robust structure minimizes vibration during cutting, ensuring even greater precision and extending the lifespan of both the machine and its cutting components.

Operator safety is a top priority in the design of the MC-315CNC. The machine includes:

Emergency stop buttons strategically located for quick shutdown

Interlock systems to prevent accidental operation

Guarding to shield users from moving parts

Secure clamping mechanisms to hold pipes in place during operation

These features reduce the risk of accidents and create a safer working environment, in compliance with modern occupational safety requirements.

Depending on the specific production needs, the machine can be equipped with optional accessories such as:

Pipe support rollers

Additional cutting heads for higher throughput

Integrated material handling systems

Cooling systems for high-speed or thermal-sensitive cuts

Dust or chip extraction setups

These upgrades allow users to customize the machine for increased productivity and efficiency, tailoring the setup to fit their workflow and scale of operations.

The VIGERT MC-315CNC Pipe Cutting Machine serves a wide variety of sectors including:

Metal fabrication workshops

Plumbing and HVAC systems manufacturing

Automotive frame and exhaust production

Construction and scaffolding systems

Aerospace and defense

Shipbuilding and marine infrastructure

Oil and gas pipeline preparation

Agricultural machinery production

From prototyping to mass production, this machine offers the consistency, speed, and precision demanded by these industries.

We offer worldwide delivery options for the VIGERT MC-315CNC. Depending on your preference and urgency:

Air freight: Estimated delivery in 7–10 days

Sea freight: Estimated delivery in 30–45 days for most global locations

Shipping timelines may vary depending on customs clearance and port accessibility in the destination country. All machines are packaged securely for international transport and include user documentation and setup instructions.

100% brand new unit manufactured in 2024

Backed by one of the industry’s leading names—VIGERT

Full CNC automation for high-volume or precision-demanding projects

Durable construction for industrial reliability

Worldwide shipping and support

Suitable for a wide range of industries and materials

Whether you’re upgrading an outdated cutting process or setting up a new line, the MC-315CNC provides both performance and peace of mind.

The VIGERT MC-315CNC can accommodate a wide range of pipe diameters and wall thicknesses. Please contact us with your specific requirements, and we’ll confirm the compatibility or recommend the right configuration.

Yes. While the machine is designed primarily for metals, it is fully capable of cutting plastic, PVC, and other non-metallic pipes with the appropriate settings and blades.

Basic installation and setup can be performed by a skilled technician with the provided manual. However, we recommend having a trained CNC operator or technician for calibration and full optimization. Support can be arranged upon request.

Yes, the CNC control system allows for multi-step cutting operations. You can predefine multiple lengths and angles, and the machine will execute them in sequence without manual intervention.

Standard models are typically configured for three-phase power. Voltage and frequency can be adjusted according to your local standards—please specify this at the time of order.

We offer a standard 12-month warranty on all new machines, covering manufacturing defects and essential components. Extended warranties and maintenance packages are also available.

Yes. Machine Matcher maintains a global network of suppliers and technicians. We can help source spare parts and provide service support as needed.

If you are looking for a specific machine or want to know if the VIGERT MC-315CNC Pipe Cutting Machine is the right fit for your project, contact us today. We will use our international network to match you with the best equipment.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Copyright 2026 © Machine Matcher.