To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

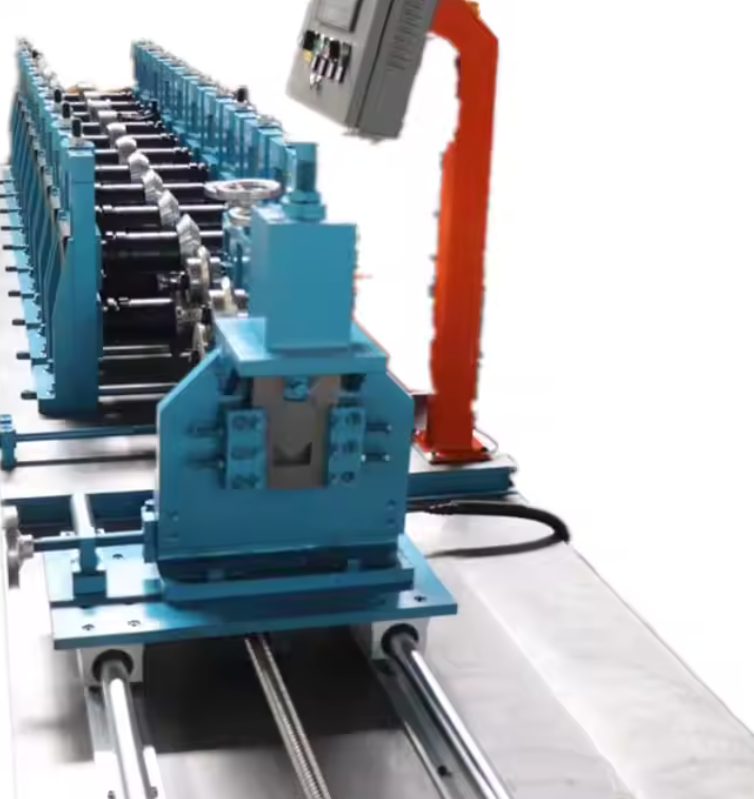

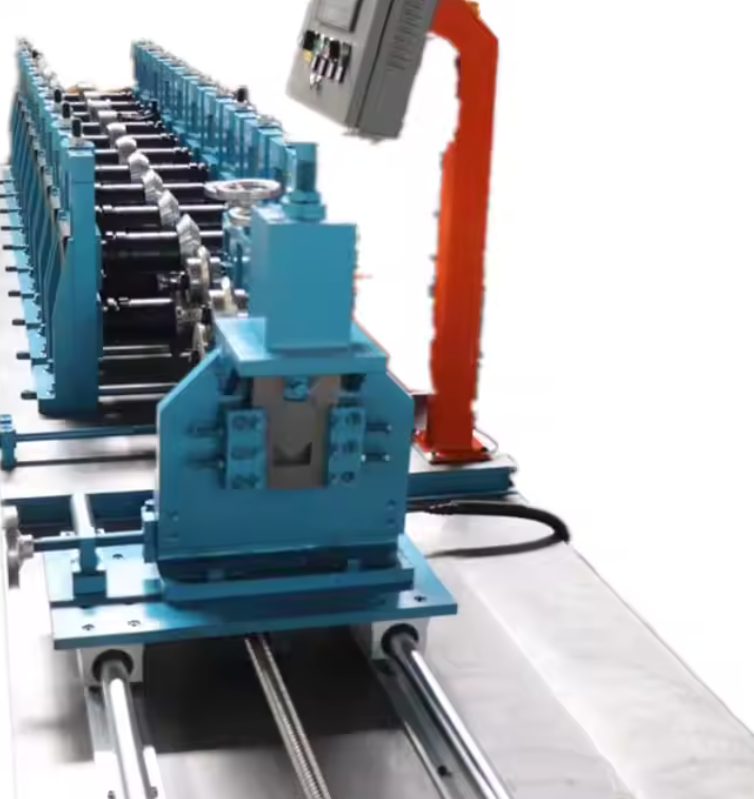

Wall Angle Roll Forming Machine – Supplied by Machine Matcher in the UAE

Machine Matcher is proud to offer precision-engineered Wall Angle Roll Forming Machines, tailored for the United Arab Emirates market, including Abu Dhabi, Dubai, and Sharjah. These machines are designed to produce high-quality L-shaped wall angle profiles, essential for suspended ceiling systems and interior framing applications.

Our Wall Angle Roll Forming Machines cater to various sectors:

Construction & Building Materials: Manufacturing components for suspended ceilings and partition systems.

Interior Fit-Out & Drywall Systems: Producing precise wall angle profiles for aesthetic and structural purposes.

HVAC & MEP Contractors: Creating support structures for ductwork and piping installations.

Architectural Finishing: Fabricating decorative trims and edge protections.

These machines are integral in producing consistent and accurate profiles, ensuring efficiency and quality in various construction and interior applications.

Machine Type: Fully Automatic Wall Angle Roll Forming Machine

Production Speed: Up to 40 meters per minute, depending on material and profile specifications

Material Thickness Range: 0.3 mm to 0.6 mm

Material Width Range: Customized based on profile requirements

Material Types: Galvanized Steel (GI), Hot Rolled Steel (HRC), Stainless Steel

Material Yield Strength: 235–390 MPa

Roller Material: Cr12 or Cr12MoV, heat-treated for durability

Roller Surface Treatment: Chromed for corrosion resistance

Number of Forming Stations: Typically 10–14 stations

Roller Shaft Diameter: 40 mm to 50 mm

Shaft Material: 45# or 40Cr Steel, heat-treated and chrome-coated

Main Drive Type: Gear Transmission

Motor Power: 5.5 kW to 7.5 kW, depending on machine configuration

Cutting Method: Hydraulic cutting with non-stop operation

Blade Material: Cr12MoV, quenched to HRC 58–62

Control Type: PLC Control System (e.g., Delta, Siemens)

Operating Mode: Fully Automatic with Touch Screen Interface

De-coiling System: Manual or Hydraulic Decoiler, capacity up to 2.5 tons

Punching/Notching System: Optional high-speed rotary punching available

Machine Frame: Welded Steel Structure with 20 mm thick side panels

Thickness of Frame Steel: 20 mm

Profile Shape: L-shaped wall angle profiles

Profile Width and Depth: Customized as per client specifications

Length Tolerance: ±0.5 mm per 3 meters

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Machine Matcher offers extensive customization to meet specific production needs:

Profile Dimensions: Tailored to exact width and depth requirements.

Material Compatibility: Adaptable to various material types and thicknesses.

Automation Level: Options for semi-automatic or fully automatic operations.

Additional Features: Integration of punching, notching, or embossing units as needed.

Clients are encouraged to provide profile drawings or specifications to ensure the machine is built to exact requirements.

Location: All machines are new and custom-built, delivered directly to any location within the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

Installation Support: Remote video guidance is available, with on-site installation support upon request.

Lead Time: Production typically takes 30–60 days. Shipping time varies based on the destination port.

Warranty: All machines come with a one-year warranty from the date of dispatch, including durable maintenance and repair support.

Starting Price: Prices for a standard Wall Angle Roll Forming Machine start at approximately $30,000 USD.

Factors Affecting Final Price:

Level of customization

Additional features (e.g., punching units, automation level)

Material specifications

Shipping and installation requirements

For a tailored quote based on specific needs, please contact Machine Matcher directly.

Q: Can the machine be customized for our specific wall angle profile?

A: Yes, Machine Matcher specializes in custom-built machines tailored to your exact profile specifications.

Q: What materials are compatible with this machine?

A: The machine is designed to work with galvanized steel, hot rolled steel, and stainless steel, typically within a thickness range of 0.3 mm to 0.6 mm.

Q: Is remote installation support available?

A: Yes, we offer remote video guidance, and on-site installation is available upon request.

Q: What is the lead time for manufacturing and shipping?

A: Production typically takes 30–60 days, and shipping time depends on the destination port.

Q: What is the warranty period for the machine?

A: All machines come with a one-year warranty from the date of dispatch, including maintenance and repair support.

Precision Engineering: Ensures consistent and accurate profile production, reducing material waste.

High Efficiency: Fast production speeds up to 40 meters per minute increase throughput.

Customization: Machines are tailored to meet specific profile and material requirements.

Comprehensive Support: From design consultation to after-sales service, Machine Matcher provides end-to-end support.

Competitive Pricing: Offers high-quality machines at competitive prices, ensuring value for investment.

These advantages translate to cost savings, improved productivity, and enhanced product quality for buyers.

For inquiries or to receive a customized quote, please email your profile drawings and specifications to:

All machines are exclusively supplied by Machine Matcher, ensuring quality and reliability.

Copyright 2026 © Machine Matcher.