To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

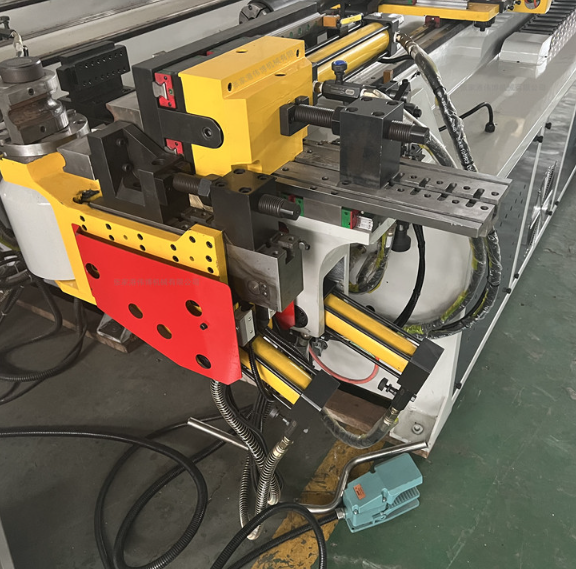

The WEIBO DW-130CNC Automatic Pipe Bending Machine is a high-performance industrial-grade bending solution designed to deliver precision, productivity, and consistency in pipe and tube fabrication. Manufactured in 2022 by WEIBO Machinery, this model offers a modern blend of CNC automation and heavy-duty mechanical construction, making it suitable for a wide range of industrial applications.

Currently in 90% new condition, this machine represents an excellent value opportunity for businesses looking to boost production without the cost of a brand-new unit. Built to the highest standards, the DW-130CNC has been engineered to withstand rigorous use while delivering repeatable accuracy in every bend.

Whether you operate in automotive, construction, shipbuilding, HVAC, furniture, or general fabrication, this machine can help you achieve fast, accurate, and reliable results across a wide array of pipe and tube materials.

Brand: WEIBO

Model: DW-130CNC

Year of Manufacture: 2022

Condition: 90% New

Machine Location: China

Function: CNC Pipe Bending (Automatic and Semi-Automatic Options)

Delivery Time:

By air: Approx. 7–10 days

By sea: Approx. 30–45 days

Equipped with a modern CNC (Computer Numerical Control) system, this machine allows operators to program and execute complex multi-angle bends with remarkable precision. The interface is user-friendly and allows for the easy storage and retrieval of bending programs, making it ideal for repeat jobs and high-volume production.

The machine is capable of handling pipes with a maximum outside diameter of 89mm (approximately 3.5 inches). The model name “DW-130CNC” indicates the series classification, supporting substantial bending strength and torque across different pipe types and wall thicknesses.

The bending radius is fully adjustable to meet diverse project requirements. This flexibility is essential for custom fabrication and specialized production tasks, such as tight-radius bends or large-radius curves, depending on tooling setup.

The DW-130CNC is compatible with a broad range of pipe and tube materials, including:

Mild Steel

Stainless Steel

Copper

Aluminum

Brass

And more, depending on tooling and material specifications.

This versatility makes the machine suitable for a wide variety of industries and bending applications.

This machine is engineered with a sturdy frame and robust structural components to handle demanding industrial use. The high-quality construction ensures minimal vibration during operation and maintains consistent output even in long production cycles.

The DW-130CNC supports both automatic and semi-automatic modes, offering the operator flexibility in terms of production style. Automatic mode is ideal for high-speed, repetitive jobs, while semi-automatic operation provides manual oversight when needed for complex or low-volume bending tasks.

The CNC programming system is designed with ease of use in mind. Operators can input precise bending angles, lengths, sequences, and material specifications via a visual interface that supports both metric and imperial measurements.

The machine is capable of bending pipes to a wide range of angles, providing the flexibility needed for diverse fabrication tasks—from sharp, small-radius turns to smooth sweeping curves.

Precision-engineered mechanical and control systems ensure tight tolerances and high repeatability, even in demanding production environments. This results in consistently accurate parts and reduced scrap material.

The machine includes a comprehensive set of safety features to protect operators and minimize the risk of accidents:

Emergency stop buttons

Safety guards

Interlock systems

Power failure protection

Compliance with safety standards makes this machine suitable for factory-floor integration in any region.

Depending on configuration and customer requirements, the DW-130CNC can be customized with additional options to enhance productivity and functionality, such as:

Mandrel Bending Attachments – For tight-radius bending with reduced deformation

Automatic Tube Loaders – For higher throughput

Advanced Control Software – For more complex geometries and offline programming

Extended Memory Storage – For storing large numbers of part programs

Cooling and Lubrication Systems – To extend tooling life and reduce wear

The WEIBO DW-130CNC is widely used in various industries, including:

Automotive – Exhaust pipes, fuel lines, roll cages

Furniture – Chair frames, table legs, metal structures

Construction – Structural tubing, handrails, piping systems

Shipbuilding – Hydraulic systems, railings, support structures

HVAC – Refrigeration and ventilation tubing

Aerospace and Rail – Lightweight tube bending for systems and framework

A cost-effective, nearly-new model from a reliable manufacturer

High productivity through automatic CNC operation

Wide material and pipe size compatibility

Suitable for medium to large-scale manufacturing operations

Backed by expert support and a global delivery network

We ship globally, directly from China. Two primary delivery options are available:

By Air Freight: Typically takes 7–10 days and is ideal for urgent delivery requirements.

By Sea Freight: Most economical for large machinery; standard delivery time is approximately 30–45 days.

Customs handling, export documentation, and packing are all managed by our logistics team to ensure smooth delivery from factory to your facility.

A: The DW-130CNC can bend pipes up to a maximum outside diameter of 89mm (3.5 inches).

A: Yes. With the correct tooling setup, it can bend stainless steel, as well as mild steel, aluminum, copper, and other materials.

A: It supports both automatic and semi-automatic operation, offering flexibility depending on your production needs.

A: The DW-130CNC can bend to a variety of angles, programmable via its CNC control system. Exact limits depend on tooling and material.

A: Yes, it includes multiple safety mechanisms such as emergency stop buttons, interlocks, and protective guards.

A: Delivery by air takes 7–10 days; by sea, it typically takes 30–45 days, depending on your location.

A: Absolutely. The CNC system allows you to input and save multiple bend profiles for quick recall and automated processing.

A: Contact us with your specifications. We’ll use our global network to find exactly what you need—new or used.

If you’re interested in the WEIBO DW-130CNC Automatic Pipe Bending Machine, or you're looking for a different model or specification, we’re here to help. Our international team can source machines, arrange inspections, and coordinate delivery to your site—anywhere in the world.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Copyright 2026 © Machine Matcher.