To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

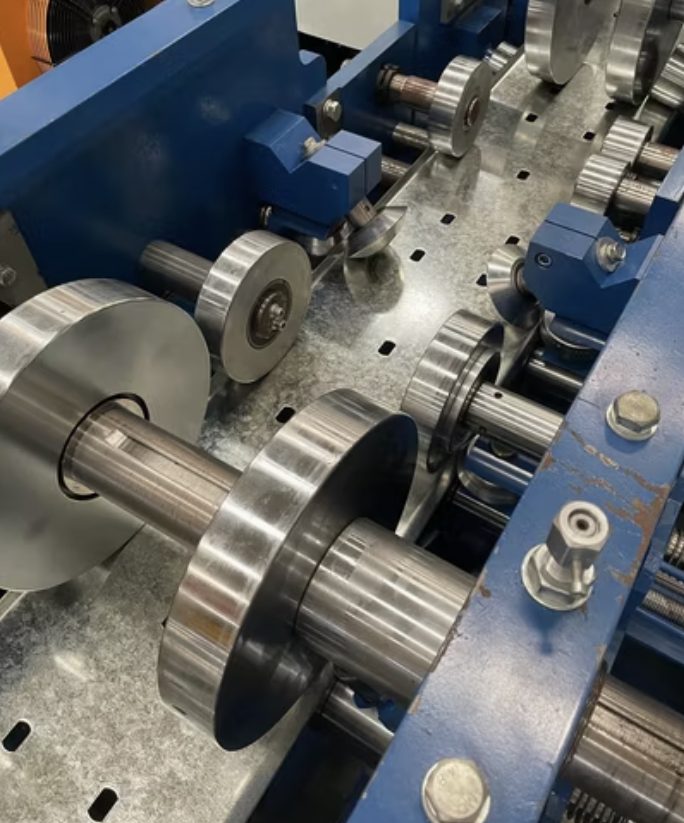

The Z purlin roll forming machine is a specialized equipment used to manufacture Z-shaped steel purlins, a critical component in modern construction and infrastructure projects. Z purlins provide support for roofs and walls in industrial, commercial, and residential buildings. This roll forming machine is designed for high-speed, precision production of Z purlins in various sizes and thicknesses, ensuring durability and conformity to industry standards.

| Specification | Details |

|---|---|

| Roller Material | High-grade chromium steel (Cr12), heat-treated for durability. |

| Frame Structure | Heavy-duty steel frame for stability and vibration reduction. |

| Thickness Range | 1.5 mm to 3.0 mm (customizable for specific applications). |

| Profile Sizes | Width: 80–300 mm; Height: 40–100 mm (adjustable) |

| Material Type | Galvanized steel, mild steel, stainless steel, and aluminum. |

| Motor Power | 11–15 kW main motor, 5.5 kW hydraulic motor for cutting. |

| PLC Control System | Mitsubishi, Siemens, or Delta PLC with a touch screen interface. |

| Cutting System | Hydraulic cutting with Cr12Mov steel blade for precise and burr-free cuts. |

| Machine Speed | Up to 20–30 meters per minute, depending on the profile size and material. |

| Voltage | Customizable (e.g., 380V, 50Hz; 440V, 60Hz) to match regional requirements. |

| Forming Stations | 14–20 forming stations for high precision. |

| Coil Width | 200–600 mm |

| Decoiler Capacity | 5–10 tons |

| Safety Features | Emergency stop, safety guards, and operational alarms. |

Q1: What materials can the Z purlin roll forming machine handle?

A: The machine is designed to process galvanized steel, mild steel, stainless steel, and aluminum in thicknesses ranging from 1.5 mm to 3.0 mm.

Q2: How do I adjust the machine for different Z purlin sizes?

A: The machine features an adjustable roller system and PLC-controlled settings, allowing quick changes to width, height, and thickness.

Q3: Can this machine operate in regions with different power specifications?

A: Yes, the machine’s voltage can be customized to match the regional power supply (e.g., 380V, 50Hz or 440V, 60Hz).

Q4: What is the typical production speed of the machine?

A: The machine can produce Z purlins at a speed of up to 20–30 meters per minute, depending on the material and profile dimensions.

Q5: What safety features are included?

A: The machine is equipped with emergency stops, safety guards, and operational alarms to ensure safe operation.

Q6: How often should maintenance be performed?

A: Basic cleaning and lubrication should be done after every production run, while a detailed inspection should occur monthly.

Q7: Is it possible to integrate additional features like remote monitoring?

A: Yes, optional extras like remote PLC systems and automated stackers can be integrated for enhanced functionality.

Q8: What is the delivery time for a Z purlin roll forming machine?

A: Delivery time varies but typically ranges from 45 to 60 days after order confirmation, depending on customization requirements.

Copyright 2026 © Machine Matcher.