To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

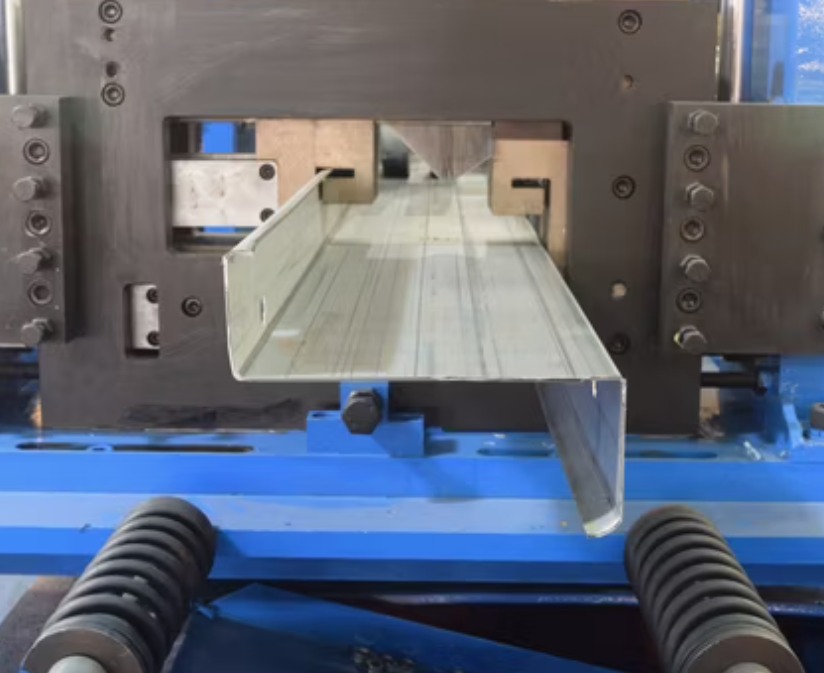

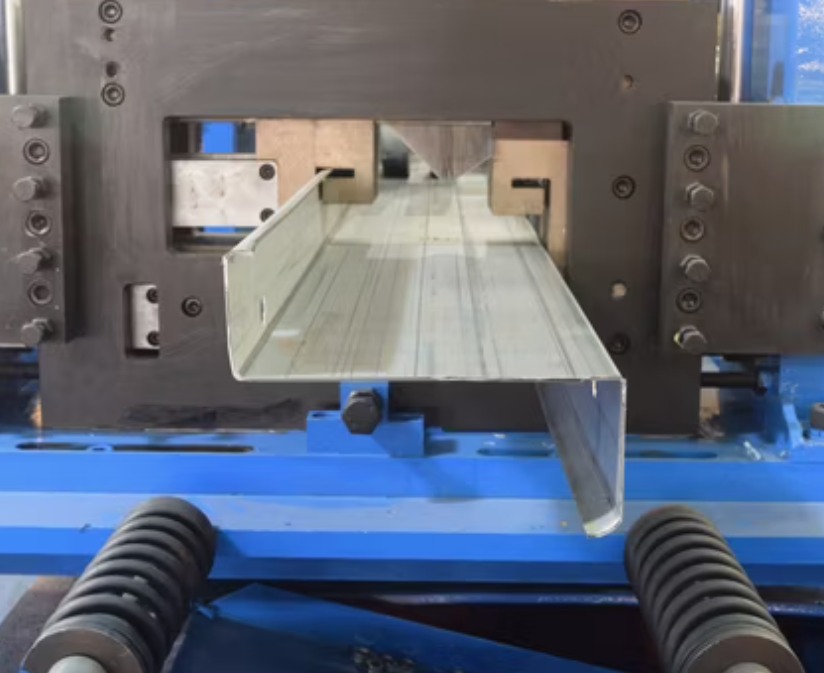

Z Purlin Roll Forming Machine – UAE Supply

Product Overview:

The Z Purlin Roll Forming Machine is a high-performance, precision-engineered solution designed for the efficient production of Z-shaped structural steel profiles commonly used in pre-engineered buildings (PEBs), warehouses, factories, solar mounting structures, carports, and various steel construction frameworks across the UAE. This machine is capable of producing purlins in various sizes and thicknesses, ensuring structural integrity and uniformity across all outputs.

Built for demanding industrial applications, this roll forming system is fully automatic, customizable to your specific profile dimensions, and capable of operating under the unique power and environmental conditions found in the UAE. From Abu Dhabi to Dubai, Sharjah, and across the Emirates, this machine supports local steel construction growth with rapid production and reliable automation.

Machine Technical Specifications:

Machine Type: Fully Automatic Z Purlin Roll Forming Machine

Production Speed: 10–20 meters/min (adjustable depending on profile and punching needs)

Material Thickness Range: 1.5 – 3.2 mm

Material Width Range: 100 – 600 mm (customizable based on profile)

Material Types: Galvanized steel, cold-rolled steel, HR steel, high-tensile steel

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 (hardened and tempered steel)

Roller Surface Treatment: Hard chrome plated for wear resistance and extended service life

Number of Forming Stations: 16–24 stations (depending on profile complexity)

Roller Shaft Diameter: 75 mm

Shaft Material: High-grade 45# steel, precision ground

Main Drive Type: Gearbox or chain drive (based on requirement)

Power (UAE-compatible): 380V / 50Hz / 3-Phase

Motor Power: 15–22 kW (depending on configuration and punching load)

Cutting Method: Hydraulic cutting system with post-cutting technology

Blade Material: Cr12MoV, heat-treated for high durability

Control Type: PLC control system (Siemens or Delta) with touch screen interface

Operating Mode: Fully automatic with manual override

De-coiling System: Hydraulic or manual uncoiler (3–10 tons capacity optional)

Punching/Notching System: Integrated hydraulic punching unit (optional; with pattern flexibility)

Machine Frame: Heavy-duty H-beam or steel plate welded structure

Thickness of Frame Steel: 20–30 mm

Profile Shape: Z-shaped purlins

Profile Width and Depth: Width 100–400 mm, Flange height 40–100 mm (customizable)

Length Tolerance: ±1 mm per 6 meters

Safety Features:

Full protective covers and guards

Emergency stop button

Overload protection system

Industries Served:

This machine is ideal for the following UAE-based industries and sectors:

Steel Building and Construction (PEBs, logistics warehouses, airport hangars)

Oil & Gas Support Infrastructure

Solar Energy Sector (mounting structures for solar farms)

Commercial and Industrial Roofing & Cladding Projects

Infrastructure Projects (metro stations, ports, bridges)

Delivery & Customization:

All machines are custom-built according to the customer’s profile requirements and specifications. The Z purlin roll forming machine is manufactured to order and delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and surrounding regions.

Our machines come with a 1-year warranty from dispatch and ongoing maintenance and repair support for long-term reliability. Optional extras like auto stackers, remote PLC support, and coil tippers can be included.

Pricing:

Machine pricing is based on the configuration, optional extras (punching unit, automatic stacker, etc.), and automation level.

Contact us for a tailored quote:

📧 [email protected]

Please share your profile drawing, size range, material type and gauge, and power requirements to help us recommend the best configuration.

Q1: Can this machine make different sizes of Z purlins?

A: Yes, the machine can be designed as adjustable (manual or automatic) to produce various Z purlin sizes by changing width and height settings without the need for separate tooling.

Q2: Does the machine include a punching unit?

A: Punching is optional. We can integrate a hydraulic punching station before forming, designed to your hole patterns.

Q3: What type of profiles can be made?

A: Custom Z purlins from 100 mm to 400 mm wide with flanges and lips based on your structural engineering needs.

Q4: Is this machine suitable for solar structure manufacturing in the UAE?

A: Absolutely. Many clients in Dubai, Abu Dhabi, and Sharjah use it to produce purlins for solar mounting frames and supports.

Q5: How long does it take to deliver the machine?

A: Delivery typically takes 8–14 weeks, depending on customization and factory production queue.

Q6: What maintenance support is available?

A: We offer spare parts, remote diagnostics, and on-site service in the UAE when needed.

Why Choose Machine Matcher for Your Z Purlin Machine in the UAE?

New machines, made to order

Tailored for UAE power and climate conditions

Local and international support

Flexible options for automation and punching

Fast response with full quotation support

Get in touch with our UAE-focused team at [email protected] for expert advice, machine drawings, and a no-obligation quote.

Copyright 2026 © Machine Matcher.