To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

When precision, reliability, and performance matter in metal sheet cutting, the ZYMT Used Cutline Shearing Machine 640 stands out as a valuable asset for fabrication shops, manufacturing plants, and metalworking facilities. Built to deliver clean, straight cuts across a variety of metal types, this machine combines industrial-grade durability with accurate shearing capabilities—making it a dependable choice for businesses seeking a cost-effective solution through used machinery.

The ZYMT 640 is a cutline shearing machine, specifically designed for shearing metal sheets and plates with precision. As part of the ZYMT lineup, which is well-regarded for its robust metal fabrication machines, the 640 model offers the performance you need to keep production flowing, while maintaining tight tolerances and minimizing material waste.

This machine is categorized under used industrial equipment and is currently located in China. It's available for international shipment with flexible delivery options to suit your schedule.

Whether you’re handling mild steel, stainless steel, or aluminum sheets, this machine is designed to offer consistent shearing performance, backed by a solid structure and intelligent control.

At its core, the ZYMT 640 is a mechanical or hydraulic shear, depending on the model variation, using a pair of high-strength blades to apply shear force to the metal sheet. The shearing process ensures clean, burr-free, straight cuts, which is essential for downstream operations such as welding, forming, or assembly.

The blades can be adjusted for optimal clearance depending on material type and thickness, allowing for versatility and customization across a range of metal applications.

The “640” designation often refers to a model-specific feature—commonly the maximum sheet width in millimeters (640mm) or material thickness it can handle. However, as this machine is listed as used and some details may vary, we recommend confirming these technical specs directly to ensure they match your operational requirements.

In general, ZYMT shearing machines in this category are built to cut low to medium-gauge metals efficiently, which makes them suitable for applications like HVAC ducting, electrical cabinets, enclosures, metal signage, roofing sheets, and other fabricated components.

Shearing is all about accuracy—and this machine is built to deliver. Equipped with adjustable back gauges and advanced blade positioning systems, it supports repeatable, high-precision cuts, helping you maintain consistency across large production runs.

Precision also extends to the blade angle and clearance control, which plays a critical role in avoiding edge deformation and ensuring high-quality output for each cut.

Most industrial shearing machines, including the ZYMT 640, are driven by either a hydraulic system (known for its smooth and powerful operation) or a mechanical drive system (known for speed and reliability). These systems are engineered to produce the necessary tonnage to shear thick or hard metals efficiently.

A well-maintained power system ensures not only effective shearing but also minimal wear on the cutting blades, reducing the need for frequent replacements and lowering operational costs.

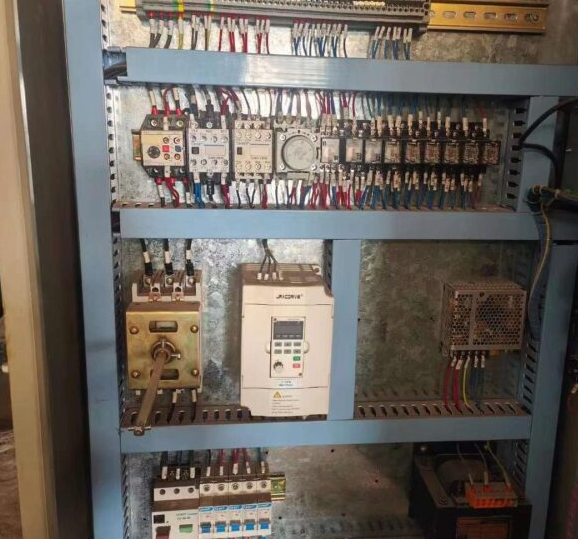

The machine is typically fitted with manual or semi-automatic control panels, offering settings for:

Blade gap adjustment

Cutting length and width

Cutting angle

Cycle times

Back gauge control

These controls enhance user flexibility, allowing operators to tailor the machine's operation based on the job at hand. This makes the machine suitable for batch production or custom cuts, depending on your workflow.

The ZYMT 640 is capable of cutting a variety of sheet materials, including:

Mild steel

Stainless steel

Galvanized sheets

Aluminum

This broad material range makes it ideal for fabricators serving industries such as automotive, construction, HVAC, consumer products, appliances, and general engineering.

Safety is a critical concern when it comes to metal cutting. This machine is expected to include essential safety features, such as:

Emergency stop button

Blade guards or protective enclosures

Interlock systems

Anti-slip foot switches

Overload protection

These features are designed to minimize risks during operation, helping ensure both safety and compliance with workplace regulations.

By automating the process of accurate sheet cutting, the ZYMT 640 helps you:

Increase throughput

Minimize material waste

Reduce manual labor

Shorten production lead times

Enhance cutting consistency

For metal fabricators looking to scale up or streamline operations, investing in a reliable used shearing machine like the ZYMT 640 can be a cost-effective way to boost productivity.

This machine is located in China and is ready for international delivery. Delivery time estimates are as follows:

By Air Freight: 7–10 days

By Sea Freight: 30–45 days (depending on your location)

We can assist in arranging logistics and customs clearance based on your delivery preferences.

Purchasing a used machine like the ZYMT Cutline Shearing Machine 640 gives you access to top-tier equipment at a fraction of the price of a new machine. It's especially beneficial for businesses that want:

Lower upfront capital investment

Immediate availability

Proven reliability

Faster ROI

Flexibility to test or scale operations

The ZYMT 640 finds use in multiple industries:

Metal fabrication workshops

Construction and roofing companies

Sheet metal contractors

Electrical and HVAC fabrication

OEM parts manufacturing

Steel service centers

Its precise cutting capabilities make it suitable for both mass production and custom orders.

While the exact specifications vary by configuration, the “640” likely refers to the maximum cutting width in millimeters. It’s best to verify with the seller for confirmation on the maximum material thickness it can cut.

Depending on the model variant, it may be hydraulic or mechanical. Hydraulic shears are smoother and quieter, while mechanical shears are faster and ideal for thinner materials.

Yes, the ZYMT 640 is suitable for cutting stainless steel, along with other metals like aluminum, mild steel, and galvanized sheet. Ensure the blade clearance and pressure settings are adjusted appropriately for stainless steel.

Air freight: 7–10 days

Sea freight: 30–45 days

We can provide a complete logistics solution depending on your preference.

Typical safety features include emergency stop buttons, blade guards, interlocks, and overload protection. Always confirm the installed safety systems when purchasing a used machine.

Yes. When you buy through Machine Matcher, we can help with setup guidance, remote support, or inspections, and even connect you with third-party service providers if needed.

Yes. You can schedule a remote video inspection or an in-person visit depending on the location and your preferences.

Depending on your region and the machine’s value, we may be able to help you explore third-party financing options or stage payments.

Just reach out to us. If you're looking for a specific machine model or specification, we’ll use our global network to source it for you.

If you're interested in the ZYMT Used Cutline Shearing Machine 640 or looking for a similar machine, get in touch with us today. We specialize in sourcing quality roll forming and metal fabrication machines across the globe.

Phone Support:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

At Machine Matcher, we connect you to machines that match your exact needs—faster, easier, and smarter.

Copyright 2026 © Machine Matcher.