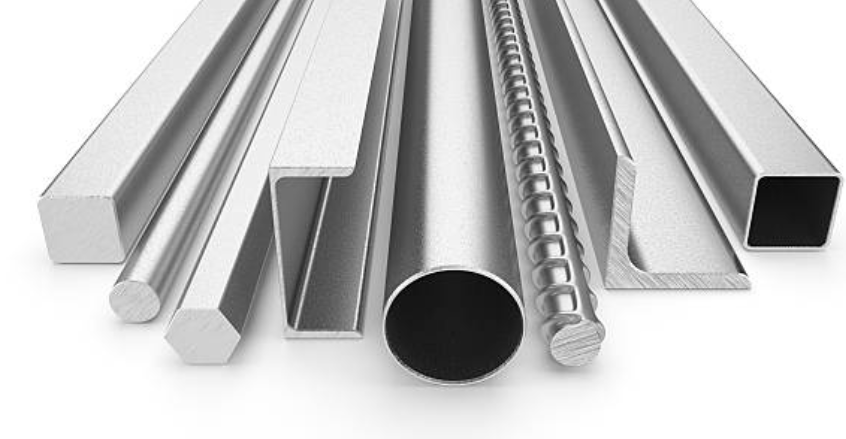

These profiles could include anything from roof panels, gutters, or structural components to more complex shapes required in industries like construction, automotive, and aerospace. The role involves a blend of engineering skills, creativity, and a deep understanding of materials and the roll forming process.

Job Title: Roll Forming Machine Profile Design Engineer

Job Description:

A Roll Forming Machine Profile Design Engineer is responsible for creating detailed designs of metal profiles that can be efficiently and accurately produced using roll forming machines. The engineer works closely with clients to understand their requirements, designing custom profiles and ensuring the machine tooling is optimized to produce these profiles.

Key Responsibilities:

- Profile Design:

- Create detailed profile designs based on client specifications or industry standards.

- Utilize CAD software (e.g., AutoCAD, SolidWorks) to develop 2D and 3D models of metal profiles.

- Ensure the designed profiles meet structural, aesthetic, and functional requirements for the intended application.

- Tooling Design:

- Design the required rollers and dies for producing the metal profile.

- Ensure that tooling aligns with the roll forming machine’s specifications to achieve precise and repeatable results.

- Optimize tooling geometry to minimize material waste and increase production efficiency.

- Engineering Calculations and Analysis:

- Perform calculations related to material stresses, bend radii, and springback in the roll forming process.

- Analyze the mechanical properties of materials used in profile designs (e.g., steel, aluminum).

- Ensure the design meets tolerances and can be manufactured efficiently without defects like warping or cracking.

- Client Interaction and Customization:

- Collaborate with clients to understand their specific profile requirements and provide technical solutions.

- Customize profiles for specialized applications, industries, or projects.

- Provide technical guidance on profile performance, material choices, and design optimizations.

- Prototyping and Testing:

- Work with manufacturing teams to create prototypes of new profiles.

- Test prototypes for accuracy, performance, and ease of production.

- Adjust designs as necessary based on prototype results and feedback from production teams.

- Documentation and Standards:

- Produce detailed technical documentation, including profile drawings, tooling designs, and production instructions.

- Ensure compliance with industry standards for profile design and production.

- Maintain records of all designs and associated revisions for future reference.

Skills Required:

- CAD Design: Strong proficiency in CAD software, especially in designing metal profiles and associated tooling.

- Materials Knowledge: Deep understanding of the properties of metals (e.g., steel, aluminum) and how they behave in the roll forming process.

- Roll Forming Process Expertise: Comprehensive knowledge of the roll forming process, including the stages of forming, material handling, and finishing operations.

- Problem-Solving: Strong analytical skills to troubleshoot design issues and optimize the production process.

- Attention to Detail: Ability to create highly detailed and precise profile designs that meet tight tolerances.

- Communication Skills: Excellent communication skills to collaborate with clients, manufacturers, and other engineers effectively.

Educational Requirements:

- Bachelor’s Degree in Mechanical Engineering, Manufacturing Engineering, or a related field.

- Additional certification or training in roll forming technology and metalworking would be an advantage.

Experience:

- Experience in designing profiles specifically for roll forming processes.

- Prior work with roll forming machines or related equipment in manufacturing is highly desirable.

- Familiarity with tooling design for metal forming processes is beneficial.

Career Growth:

- A Profile Design Engineer can progress to senior engineering roles, including Lead Design Engineer, Technical Manager, or Project Engineer within roll forming or manufacturing firms.

- Opportunities may also exist to move into product development or R&D roles focused on advanced roll forming technologies and materials.

Industry Applications:

- Construction: Designing profiles for roofing, wall cladding, structural beams, gutters, and other building components.

- Automotive: Creating profiles for vehicle frames, body components, and safety systems.

- Aerospace: Designing lightweight but strong profiles for aircraft structures.

- Energy: Developing profiles for solar panel mounts, wind turbine towers, and other energy infrastructure.

In this role, you play a pivotal part in bridging client needs with manufacturing capabilities, ensuring high-quality, precise, and cost-effective metal profiles are delivered.

4o