When sourcing roll forming machines in Saudi Arabia, buyers should consider several critical factors to ensure they make a well-informed purchase that meets their specific manufacturing needs. Here are key considerations to keep in mind:

1. Technology Features

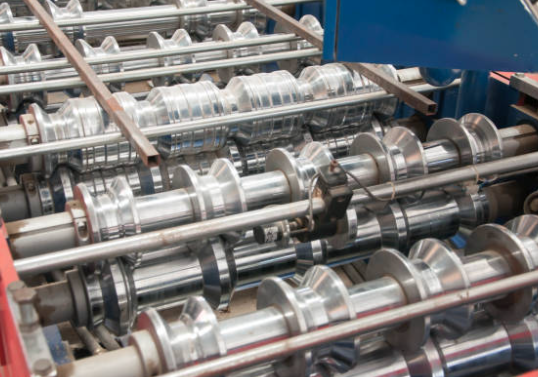

- Precision and Consistency: Look for machines that offer high precision in profile production. Features such as adjustable tooling and advanced control systems can significantly enhance consistency in the final products.

- Speed and Efficiency: Assess the machine's production speed and efficiency. High-speed machines can help meet tight deadlines, while energy-efficient models can reduce operating costs.

- Customization Options: Ensure that the machine can be customized for various profiles. Flexibility in design allows for a wider range of applications, accommodating the specific needs of your projects.

- Automation Capabilities: Advanced automation features, such as integrated cutting and stacking systems, can enhance productivity by reducing manual labor and minimizing errors.

2. Supplier Reputation

- Experience and Expertise: Research the supplier’s background, including their years in the industry, experience with roll forming technology, and expertise in the specific types of machines you are considering.

- Client References: Request references from previous customers. Positive feedback and case studies can provide insight into the supplier's reliability and product performance.

- Industry Presence: Evaluate the supplier's presence in the local and regional markets. A well-established supplier with a strong network can offer better support and service.

3. After-Sales Support

- Maintenance and Service: Confirm the availability of maintenance services and technical support. A responsive after-sales service can help minimize downtime and ensure smooth operation of the machinery.

- Training and Documentation: Ensure that the supplier provides comprehensive training for your staff on machine operation and maintenance, along with detailed manuals and documentation.

- Spare Parts Availability: Check the supplier’s ability to provide spare parts promptly. Quick access to replacement parts can significantly reduce potential production disruptions.

4. Compliance and Certifications

- Quality Standards: Verify that the machines meet international quality standards and certifications. Compliance with safety and environmental regulations is essential for ensuring operational safety and sustainability.

- Local Regulations: Familiarize yourself with any local regulations in Saudi Arabia regarding manufacturing and equipment. Ensuring compliance can prevent legal issues and fines.

5. Cost Considerations

- Budgeting for Total Cost of Ownership: Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, operational costs, and energy consumption over the machine's lifespan.

- Financing Options: Inquire about financing options or payment plans offered by the supplier to make the purchase more manageable.

Conclusion

Sourcing roll forming machines in Saudi Arabia requires careful consideration of various factors, from technology features to supplier reputation and after-sales support. By thoroughly evaluating these aspects, buyers can ensure they invest in reliable, high-quality equipment that meets their manufacturing needs, ultimately contributing to the success of their operations in the competitive market.