To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

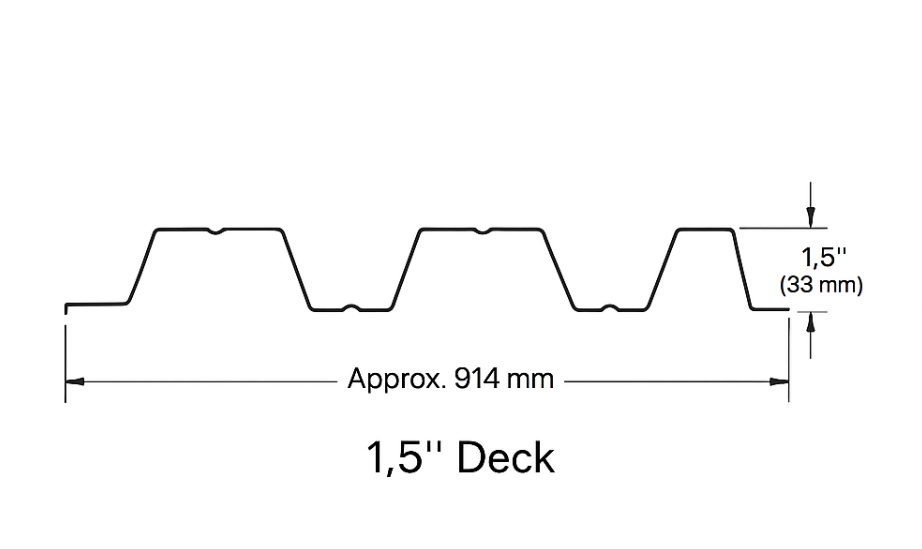

1.5” Deck Roll Forming Machine – UAE Market

The 1.5" Deck Roll Forming Machine is a high-performance, precision-engineered industrial solution designed for producing structural floor decking panels with a profile depth of 1.5 inches (38mm). It is ideally suited for construction and infrastructure projects across the UAE, including high-rise buildings, commercial developments, and industrial warehouses that require efficient floor support systems. This machine transforms high-tensile steel coils into uniform, high-strength deck panels ready for on-site installation or further processing.

Manufactured for the demanding conditions of the UAE construction sector, the 1.5" deck roll forming machine combines speed, durability, and flexibility. Its rugged frame, high-speed operation, and customization capabilities make it suitable for contractors and manufacturers working under tight timelines and with varying profile requirements.

This machine is widely used in the following industries:

Commercial Construction: For multistory office buildings, malls, and mixed-use complexes requiring composite slab systems.

Industrial Warehousing & Logistics: For mezzanine flooring and heavy-load floor structures.

Infrastructure Projects: Such as airports, seaports, and government buildings requiring rapid deployment of large flooring sections.

Residential Projects: Especially in villas and apartment blocks with steel-concrete composite floors.

The demand for metal decking in the UAE continues to grow, particularly in rapidly expanding cities like Dubai, Abu Dhabi, and Sharjah, making this machine a vital asset for local manufacturers and fabricators.

Machine Type: 1.5" Deck Roll Forming Machine

Production Speed: 15–30 meters per minute (adjustable based on material and profile)

Material Thickness Range: 0.7 mm – 1.5 mm

Material Width Range: 900 mm – 1250 mm (depending on final profile design)

Material Types: Galvanized steel, Galvalume, Cold-rolled steel

Material Yield Strength: Up to 550 MPa (suitable for structural applications)

Roller Material: GCr15 high-grade steel, quenched and hardened

Roller Surface Treatment: Hard chrome plated for corrosion resistance and durability

Number of Forming Stations: 24–28 stations (customized based on design)

Roller Shaft Diameter: 80 mm

Shaft Material: 40Cr precision machined and heat treated

Main Drive Type: Chain or Gear Drive (as required)

Power (UAE voltage): 380V / 3 Phase / 50Hz

Motor Power: Approx. 15–22 kW (depending on design and punching requirements)

Cutting Method: Hydraulic post-cutting

Blade Material: Cr12Mov steel, heat treated and ground

Control Type: PLC with HMI touchscreen (Siemens, Delta, or Mitsubishi)

Operating Mode: Automatic + Manual for setup and testing

De-coiling System: Hydraulic or manual uncoiler, 5–10 ton capacity

Punching/Notching System: Optional (as per customer drawing)

Machine Frame: Welded steel frame, CNC machined for alignment

Thickness of Frame Steel: 20 mm

Profile Shape: Trapezoidal deck profile, 1.5" (38mm) rib depth

Profile Width and Depth: Effective width ~914 mm, depth 38 mm (adjustable)

Length Tolerance: ±2.0 mm per 6000 mm length

Protective Covers/Guards over moving parts

Emergency Stop Buttons at critical points

Overload Protection System integrated into main drive

CE-compliant electrical and control system on request

Prices Start From: USD $65,000 (depending on configuration, automation, and options)

What Affects Final Price:

Addition of automatic stacker, servo feeding, hydraulic punchers

Uncoiler type (manual vs hydraulic)

Profile width customization

Material thickness requirements

Branded vs generic electronic components

All machines are new and custom-built to meet your specific profile and production requirements. This machine can be delivered anywhere in the United Arab Emirates, including:

Abu Dhabi

Dubai

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Machines are supplied directly from our international manufacturing partners, and every machine includes a one-year warranty from the dispatch date, along with robust maintenance and technical support.

To ensure you receive the most accurate quote tailored to your needs, we encourage you to send:

Profile drawing or sketch (PDF/DWG)

Material specifications (type, thickness, yield strength)

Required machine speed

Coil width

Power requirements

Send all quote details to: [email protected]Frequently Asked Questions (FAQ)

Q: Can this machine handle high-strength steel coils common in UAE?

A: Yes. It supports up to 550 MPa yield strength, ideal for structural floor decking.

Q: What kind of maintenance does the machine require?

A: Standard lubrication, roller cleaning, and occasional alignment checks. Machine Matcher offers annual maintenance packages on request.

Q: Can you customize the profile according to our UAE consultant’s drawings?

A: Absolutely. Each machine is built-to-order based on your technical drawings and job site needs.

Q: How long is the lead time for delivery in the UAE?

A: Typical production time is 45–60 days. Delivery to the UAE usually adds another 15–20 days depending on customs and shipping arrangements.

Q: Are installation and training services available in the UAE?

A: Yes. We provide remote setup support, and on-site commissioning and training can also be arranged at additional cost.

Q: Is this machine compliant with UAE safety and electrical standards?

A: Yes. All machines can be configured to meet local safety codes and electrical standards (380V / 50Hz / 3 Phase).

The 1.5" Deck Roll Forming Machine is a powerful, customizable solution for companies in the UAE that need to produce structural steel decking panels efficiently and accurately. Whether for infrastructure expansion in Dubai or residential builds in Abu Dhabi, this machine ensures consistency, reliability, and low long-term operational cost. Backed by Machine Matcher’s global sourcing and regional support, it’s an essential investment for modern construction and fabrication businesses in the Gulf region.

Copyright 2026 © Machine Matcher.