To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

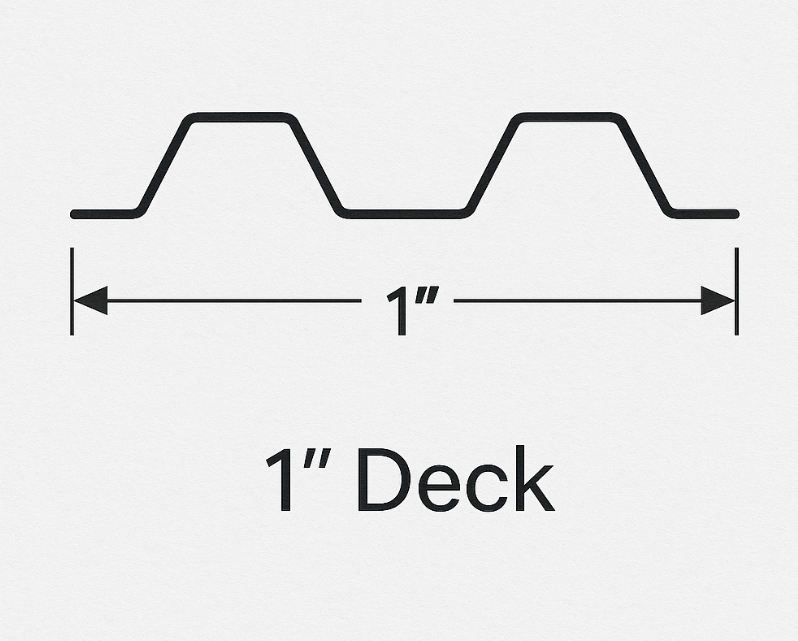

1" Deck Roll Forming Machine – United Arab Emirates

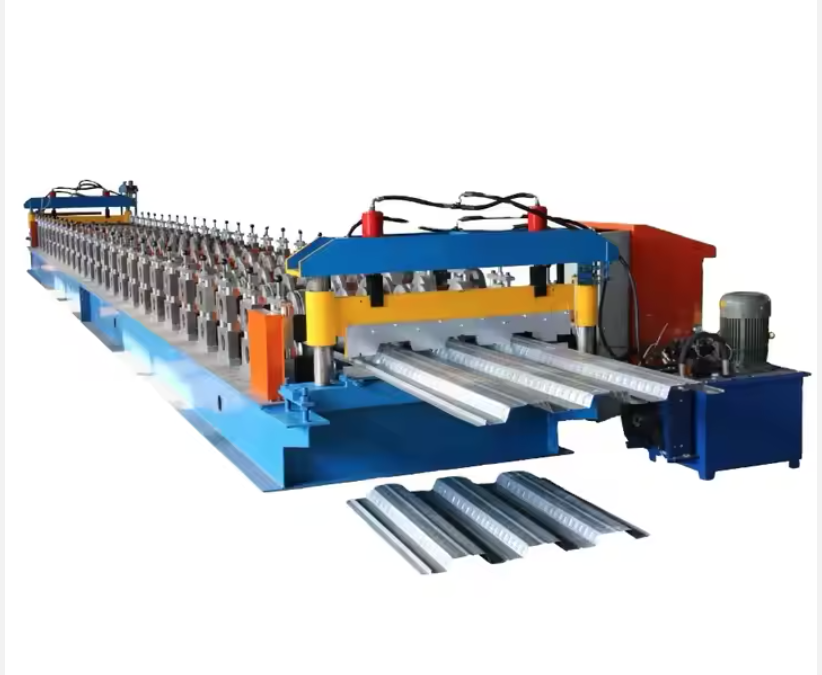

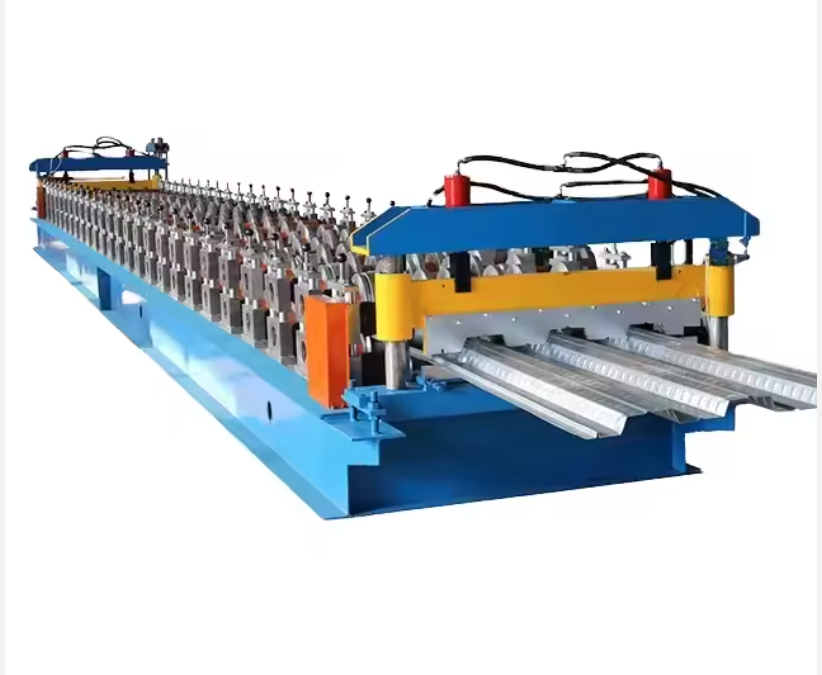

The 1" Deck Roll Forming Machine is a precision-engineered production solution designed to manufacture 1-inch floor and roof deck panels with speed, accuracy, and durability. Built for the rigorous demands of the UAE construction and infrastructure sectors, this machine supports large-scale commercial, industrial, and institutional building projects. Whether you're operating in Abu Dhabi, Dubai, Sharjah, or anywhere else in the Emirates, this fully customizable machine is engineered for seamless local operation and long-term performance in high-temperature and heavy-duty environments.

This machine is widely used across:

Commercial buildings – multi-story office towers and shopping malls

Industrial warehouses – logistics centers, free zone facilities

Public infrastructure – schools, hospitals, metro stations

Airport and port expansions – where lightweight, load-bearing decking is essential

Pre-engineered building (PEB) projects – especially those requiring fast-track timelines

The 1” deck profile offers a strong yet efficient flooring and roofing solution, acting as a permanent formwork during concrete pouring and providing excellent structural integrity.

Machine Type: 1" Deck Roll Forming Machine

Production Speed: 15–30 meters per minute (adjustable based on material and profile)

Material Thickness Range: 0.7mm – 1.2mm

Material Width Range: 1000mm – 1250mm (customizable based on coil size and profile design)

Material Types: Galvanized Steel, Galvalume, Aluminum (optional), PPGI

Material Yield Strength: 250 – 550 MPa

Roller Material: GCr15 (high-grade bearing steel)

Roller Surface Treatment: Hard chrome plated for corrosion resistance and surface wear reduction

Number of Forming Stations: 18–22 stations (based on profile complexity)

Roller Shaft Diameter: 70mm–90mm

Shaft Material: 45# Steel, quenched and tempered

Main Drive Type: Chain drive / gearbox drive (optional upgrade)

Power (UAE Compatible): 380V / 50Hz / 3 Phase

Motor Power: Approx. 15kW–22kW (depending on configuration and drive system)

Cutting Method: Hydraulic post-cutting system

Blade Material: Cr12Mov high-speed tool steel (heat-treated)

Control Type: PLC (Siemens or Mitsubishi-based systems)

Operating Mode: Fully automatic + manual mode for testing and maintenance

De-coiling System: Manual or hydraulic de-coiler (5–10 Ton capacity)

Punching/Notching System: Optional hydraulic punching unit for fixing holes or customized patterns

Machine Frame: Welded structure with tempered steel side panels

Thickness of Frame Steel: 18–25mm for enhanced rigidity

Profile Shape: 1” trapezoidal decking profile

Profile Width and Depth: Effective width 750–950mm / Depth 25mm

Length Tolerance: ±1.0mm per 6 meters

Protective Covers/Guards: Installed around forming rollers and cutting system

Emergency Stop Button: Strategically located on control panel and machine sides

Overload Protection System: Integrated in electrical and hydraulic circuits

Prices start from: $65,000 USD (depending on machine configuration and options)

What affects the final price:

Profile customization

Motor brand (Siemens, Delta, etc.)

Number of forming stations

Hydraulic punching or stacking system

Automation level (basic to fully automatic line)

All machines are new and custom-built to meet customer-specific profile and performance requirements.

Delivery available across the United Arab Emirates, including:

Abu Dhabi

Dubai

Sharjah

Ajman, Fujairah, Ras Al Khaimah, and Umm Al Quwain

Machines are shipped from our trusted manufacturing partners and come with:

One-year warranty from dispatch

Durable maintenance and technical support available regionally

If you already have profile drawings, material specs, or production targets, send your details to:

[email protected]

We’ll provide a tailored quotation and machine recommendation.

Q: What makes the 1” deck profile popular in the UAE?

A: It provides an optimal balance between material use and structural strength, making it ideal for lightweight slabs in multi-floor buildings and mezzanines.

Q: Can this machine produce different deck heights or widths?

A: Yes. We can customize the roll forming unit and tooling to meet your profile requirements. Send us your drawing for evaluation.

Q: Does the machine require a foundation?

A: A level concrete floor is typically sufficient. For high-speed production lines, a reinforced foundation may be recommended.

Q: What kind of maintenance is needed?

A: Regular greasing, roller cleaning, and electrical inspection are essential. We provide a full maintenance guide with each machine.

Q: Can I get operator training and installation support in the UAE?

A: Yes. Remote support is included, and on-site training can be arranged by our technical team.

Q: What coil specifications are compatible with this machine?

A: Up to 1250mm coil width, 0.7mm–1.2mm thickness, inner diameter 508mm, outer diameter up to 1300mm.

Hydraulic or motorized uncoiler

Automatic stacker

Servo feeding system

Remote PLC monitoring

Pre-punching units for embedment holes

Coil car for easy loading

Safety light curtain and enclosure upgrade

For the most reliable and project-ready 1" deck roll forming machine in the UAE, trust Machine Matcher to deliver performance, customization, and support—backed by expert service and a global supply network.

Copyright 2026 © Machine Matcher.