To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

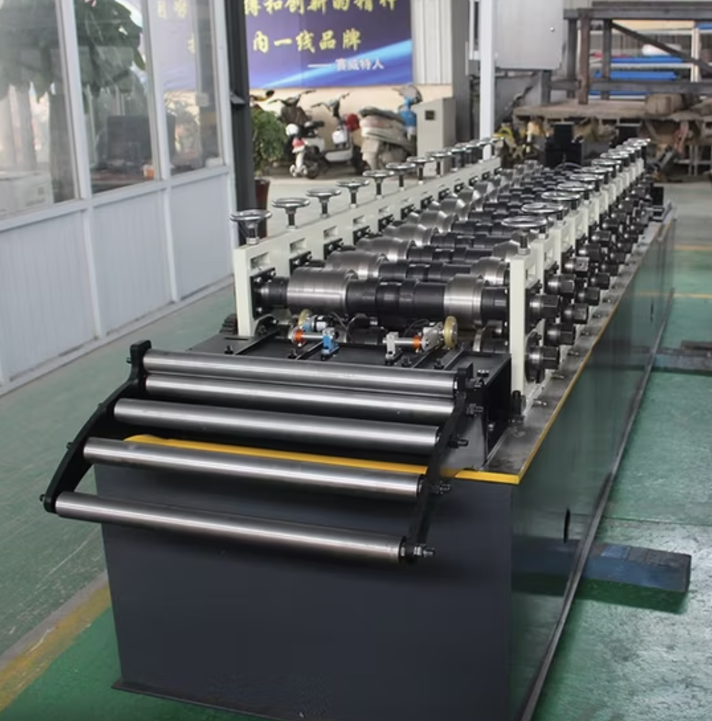

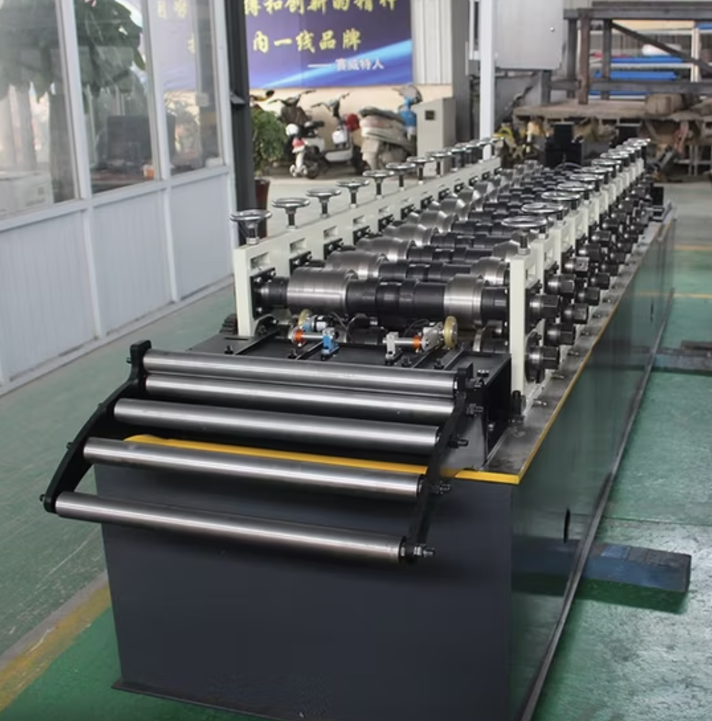

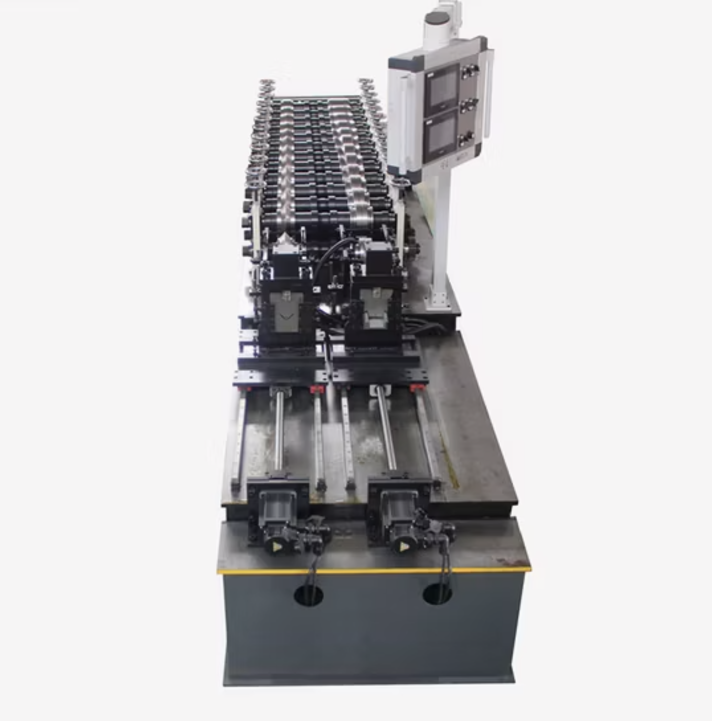

The 1-inch metal J-channel roll forming machine is a specialized piece of equipment designed to produce precise and consistent J-channel profiles, commonly used in construction, siding, drywall framing, and other industrial applications. Its robust design ensures efficiency, durability, and precision in forming metal into the J-channel shape.

The 1-inch metal J-channel roll forming machine is built with advanced engineering to meet the specific demands of the USA market. This machine processes coil stock into J-channel profiles with a width of 1 inch, suitable for various applications, including siding trim, drywall corner reinforcements, and more.

Key Features:

| Feature | Specification |

|---|---|

| Roller Material | GCr15 steel with heat treatment (hardness: 58-62 HRC) |

| Frame Structure | Welded steel frame |

| Roller Stations | 10–12 stations |

| Profile Width | 1 inch |

| Material Thickness | 0.3–0.8 mm (customizable) |

| Material Type | Galvanized steel, aluminum, stainless steel |

| Drive System | Chain drive or gear drive |

| Cutting System | Hydraulic cutting with carbide steel blade |

| Control System | PLC with touchscreen interface |

| Power Requirement | 220V/60Hz or 380V/50Hz |

| Motor Power | 5–7.5 kW |

| Machine Speed | 30–40 meters per minute |

| Safety Features | Emergency stop, protective guards |

| Optional Add-ons | Decoilers, recoilers, stackers, remote PLC |

Q1: What materials can be used with this machine?

A: The machine is compatible with galvanized steel, aluminum, and stainless steel, with material thicknesses ranging from 0.3–0.8 mm. It can be customized for other materials upon request.

Q2: Can the machine be adjusted for different profile sizes?

A: Yes, the machine can be adjusted to create custom widths or shapes based on client requirements.

Q3: What are the power requirements for operation?

A: Standard power requirements are 220V/60Hz or 380V/50Hz, suitable for USA industrial settings. Custom power configurations can be accommodated.

Q4: How fast can the machine produce J-channels?

A: The machine operates at speeds of 30–40 meters per minute, depending on material and thickness.

Q5: Is the machine compatible with automated production lines?

A: Yes, the machine can integrate with decoilers, stackers, and other automated systems for a streamlined production process.

Q6: What maintenance does the machine require?

A: Regular maintenance includes checking roller alignment, lubrication of moving parts, and cleaning to ensure consistent operation. A maintenance schedule will be provided.

Q7: Is there a warranty for the machine?

A: Typically, the machine comes with a 1–2 year warranty covering manufacturing defects. Extended warranties may be available upon request.

Q8: Can the machine be shipped and installed in the USA?

A: Yes, shipping and installation services are available for customers in the USA. A professional technician can assist with setup and training.

Copyright 2026 © Machine Matcher.