To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

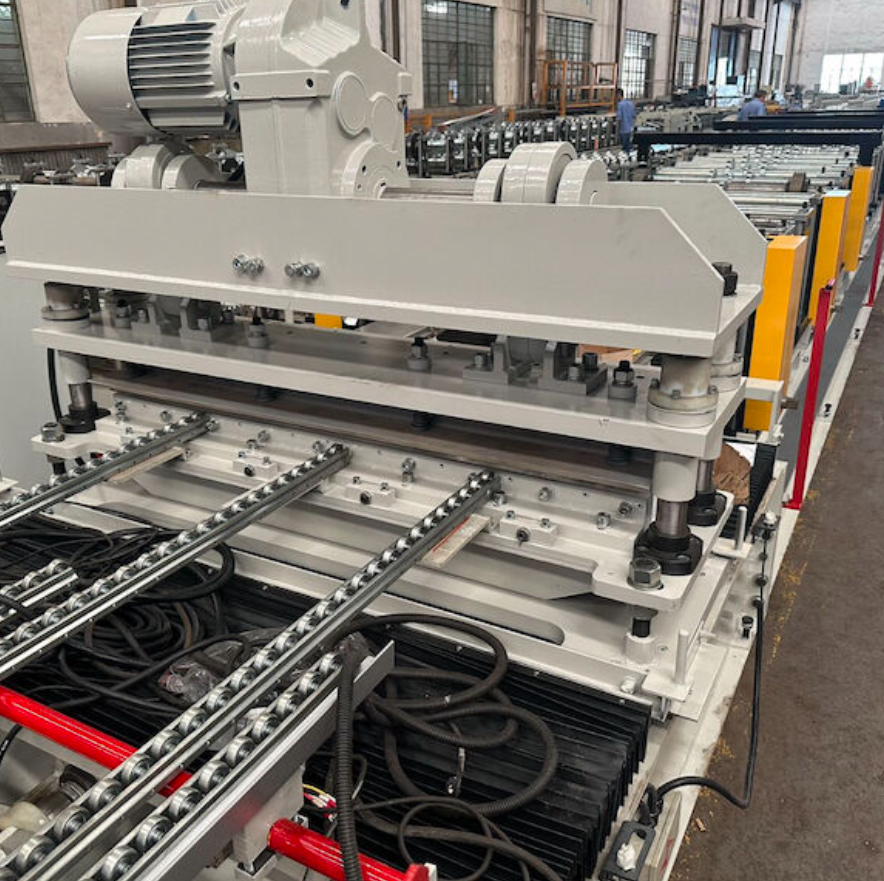

The 20 Ga Galvanized Decking Roll Forming Machine is a state-of-the-art solution for manufacturing high-quality metal decking profiles, designed to meet the demanding requirements of the construction and metal fabrication industries in Arkansas, USA. Built to last and engineered for precision, this roll forming machine is perfect for producing 20-gauge galvanized decking efficiently and consistently.

All our machines are new and custom-built to align with your specific profile and machine requirements, ensuring a seamless fit for your production line. Upon completion, the machine is shipped directly to your location from our trusted manufacturing partners.

Pricing: Custom pricing is available based on your specific requirements and optional extras. Contact us for a tailored quote.

Warranty: Includes a comprehensive one-year warranty from the dispatch date, along with reliable maintenance and repair support.

Support Services: Machine Matcher offers a complete range of services, including sales, maintenance, repair, setup, and adjustment for roll forming machines globally.

If you have profile drawings or additional details, please send them to [email protected] for an accurate quote.

The 20 Ga Galvanized Decking Roll Forming Machine is ideal for the following industries:

This machine is shipped directly to your location in Arkansas, USA, with full support for installation and setup.

Answer: Lead time varies based on customization and production schedules. Typically, delivery is completed within 12 to 16 weeks from the date of order confirmation.

Answer: Yes, we offer custom-built machines to produce various decking profiles including 1.5 inch B deck, 3 inch N deck, composite metal deck, and steel form deck. You can also send your profile drawings to [email protected] for a tailored quote.

Answer: Yes, on-site training is available for your operators to ensure efficient and safe machine operation.

Answer: You can add auto stackers, safety covers, and cassette systems to enhance the machine’s efficiency and safety.

Answer: The machine is carefully packaged and shipped directly to your location via trusted logistics partners, ensuring safe and timely delivery.

Answer: We provide durable maintenance and repair support under warranty, including spare parts and remote assistance if required.

Answer: Yes, the machine can process a range of materials within the specified 18g to 22g thickness. Contact us to discuss your material requirements.

For more information or to get a tailored quote, please contact us at [email protected] or visit our website.

Copyright 2026 © Machine Matcher.