To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

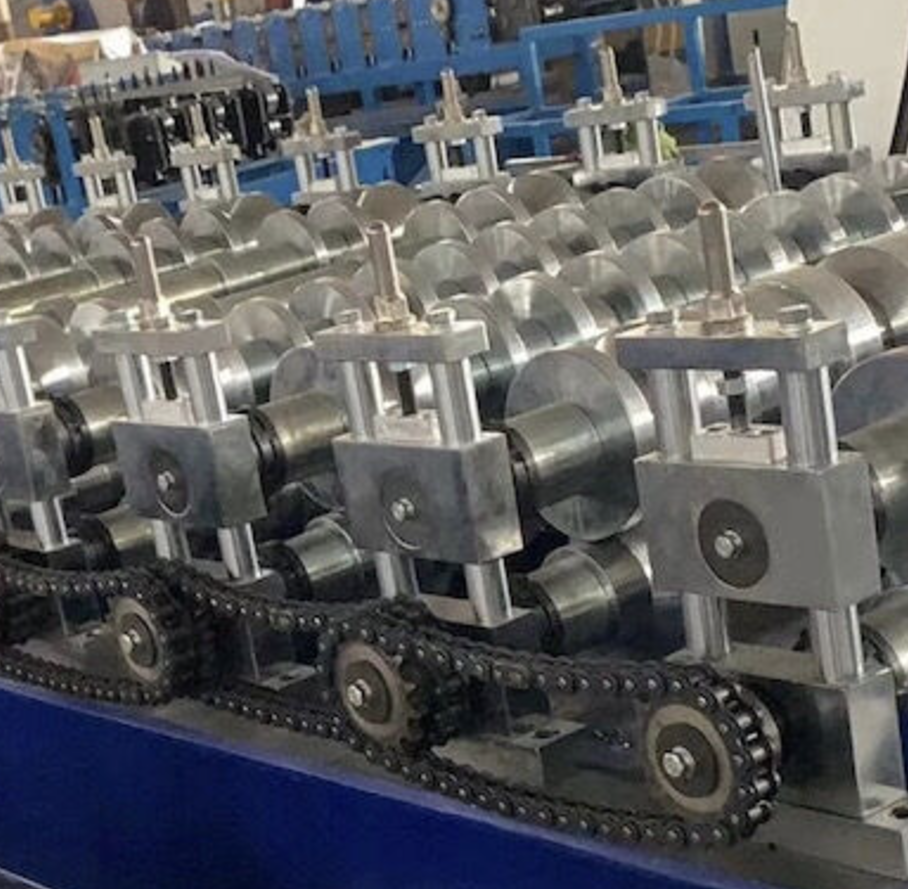

The 20-station PBR Roof Panel Cold Roll Forming Machine is a highly efficient and robust piece of equipment designed to manufacture precision-engineered PBR (Purlin Bearing Rib) roof panels. This machine caters to the growing demand for high-quality roofing solutions in Florida's construction and building industries, where durability and weather resistance are critical.

With its advanced roll forming technology, the machine transforms steel coils into PBR roof panels through a continuous process of forming, cutting, and stacking. This ensures uniformity, accuracy, and speed, making it a reliable solution for large-scale projects.

Q1: What is the forming speed of the machine?

A1: The machine operates at a speed of 15-20 meters per minute, depending on material thickness and profile requirements.

Q2: Can this machine be customized for different profiles?

A2: Yes, it supports customization to produce variations in panel designs, widths, and rib patterns.

Q3: Is the machine suitable for Florida's climate?

A3: Absolutely. It processes materials like Galvalume and painted steel that are corrosion-resistant, ideal for Florida’s humid and coastal climate.

Q4: What is the power requirement for this machine?

A4: It typically operates on 380V, 60Hz, 3-phase power, but voltage can be customized based on your facility.

Q5: How is quality ensured during production?

A5: The PLC system ensures precision control, and the hydraulic cutting system maintains consistency in panel dimensions.

Q6: What safety features are included?

A6: Safety guards, emergency stops, and overload protection are standard features to ensure operator safety.

Q7: How do I maintain the machine for long-term use?

A7: Regular cleaning, lubrication, and timely replacement of worn-out parts are essential for optimal performance.

Q8: Can the machine handle high production demands?

A8: Yes, the machine is designed for large-scale production with consistent output quality, making it suitable for industrial-scale projects.

Copyright 2026 © Machine Matcher.