To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

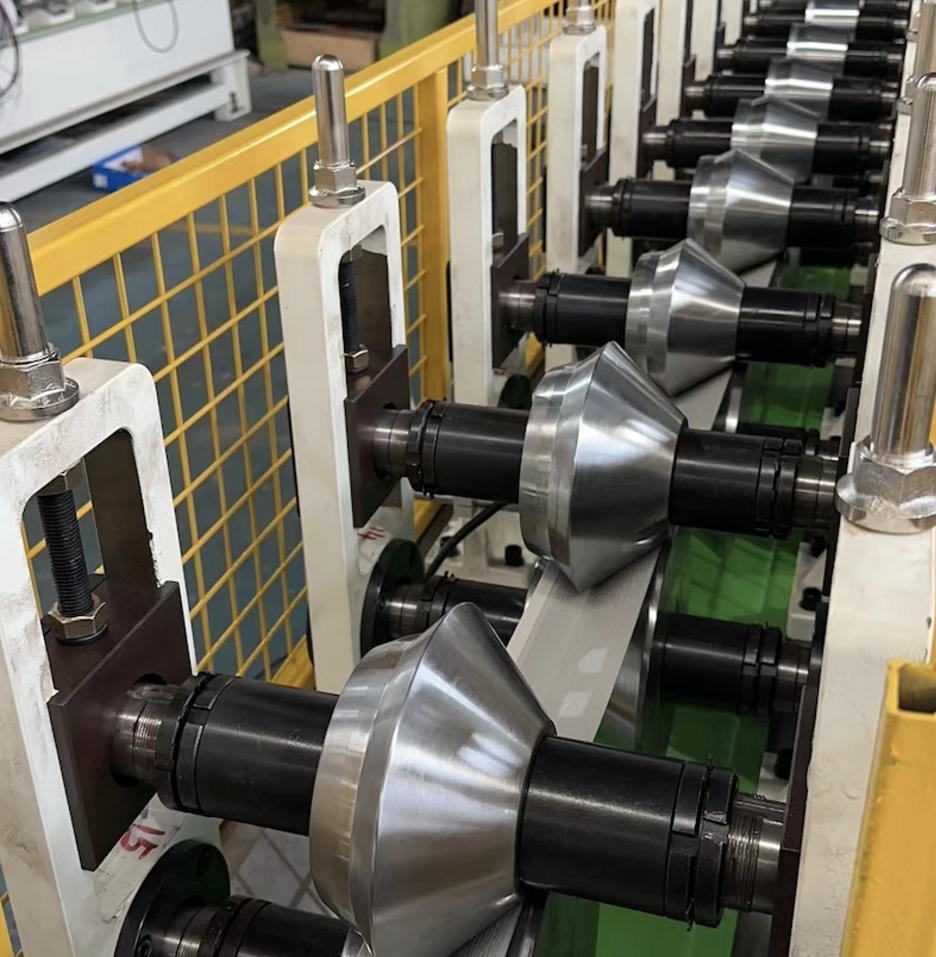

The 3-inch drip edge cold roll forming machine is designed to produce precision drip edge profiles commonly used in roofing applications for residential and commercial buildings. This specialized machine is highly efficient, delivering durable and accurately shaped drip edges that provide water runoff protection and aesthetic enhancement for roofs.

This cold roll forming machine is tailored for manufacturing 3-inch drip edges. Its design incorporates advanced technology to ensure consistent production quality. With its automated operation and robust components, the machine minimizes manual intervention, reduces production time, and ensures precision. The machine supports multiple material types, making it versatile for various applications and markets.

1. What materials can this machine process?

The machine can process aluminum, galvanized steel, stainless steel, and painted/coated steel within the specified gauge range (0.3mm to 0.8mm).

2. How much space is required for installation?

Typically, the machine requires an area of about 10m x 3m, with additional space for material handling equipment.

3. Is the machine compatible with Florida's power supply standards?

Yes, the machine's voltage and frequency can be customized to meet Florida's electrical standards.

4. Can custom drip edge profiles be produced?

Yes, the rollers can be customized to create non-standard drip edge profiles upon request.

5. What is the average production output?

The machine can produce up to 20 meters of drip edge profiles per minute, depending on the material and profile complexity.

6. What kind of training is provided?

Comprehensive training for operators is provided, including machine setup, operation, and basic troubleshooting.

7. How long is the warranty?

The machine comes with a one-year warranty, covering parts and labor for manufacturing defects.

8. Are spare parts readily available?

Yes, spare parts can be shipped directly to Florida within a short timeframe.

Copyright 2026 © Machine Matcher.