To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

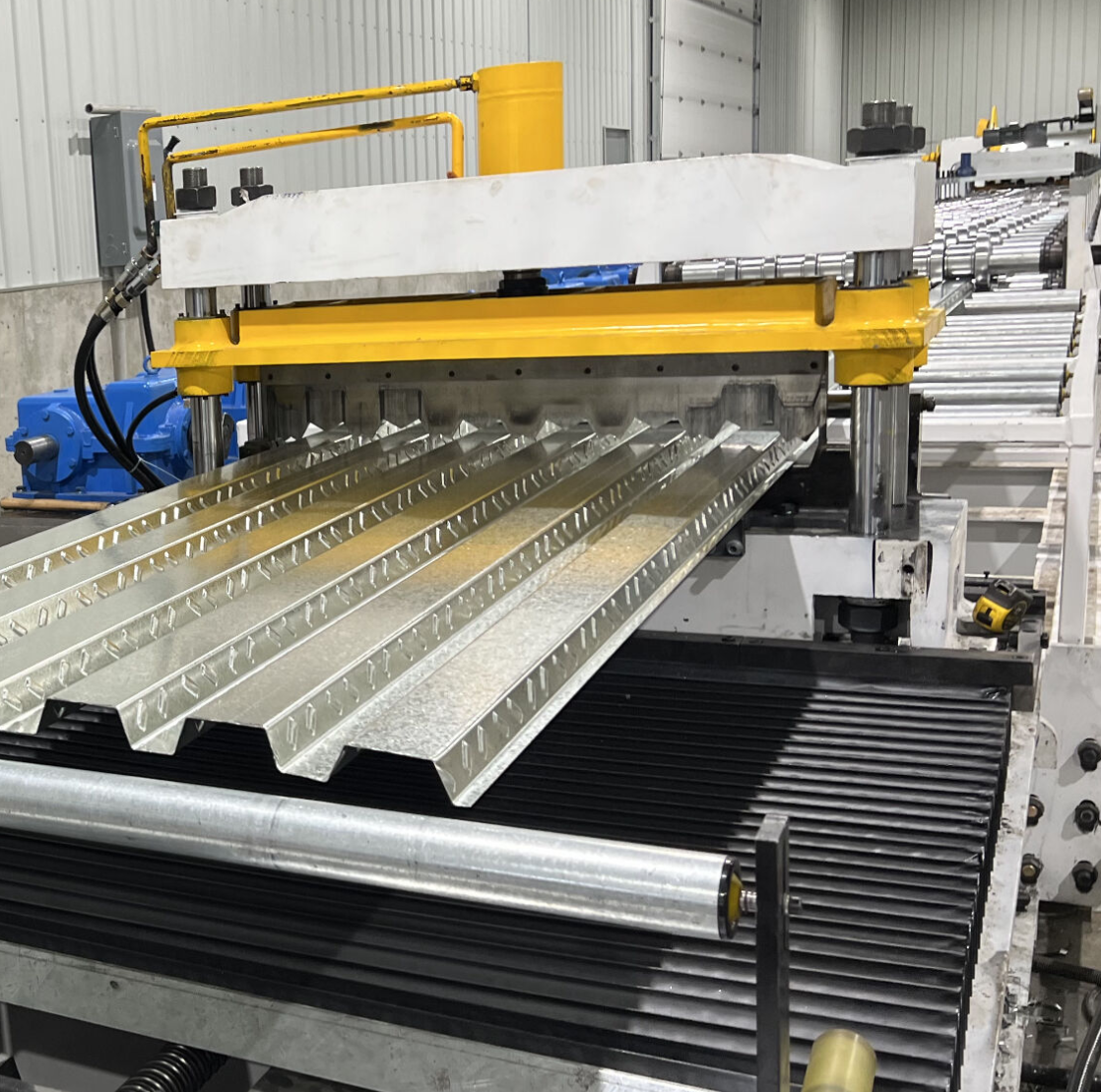

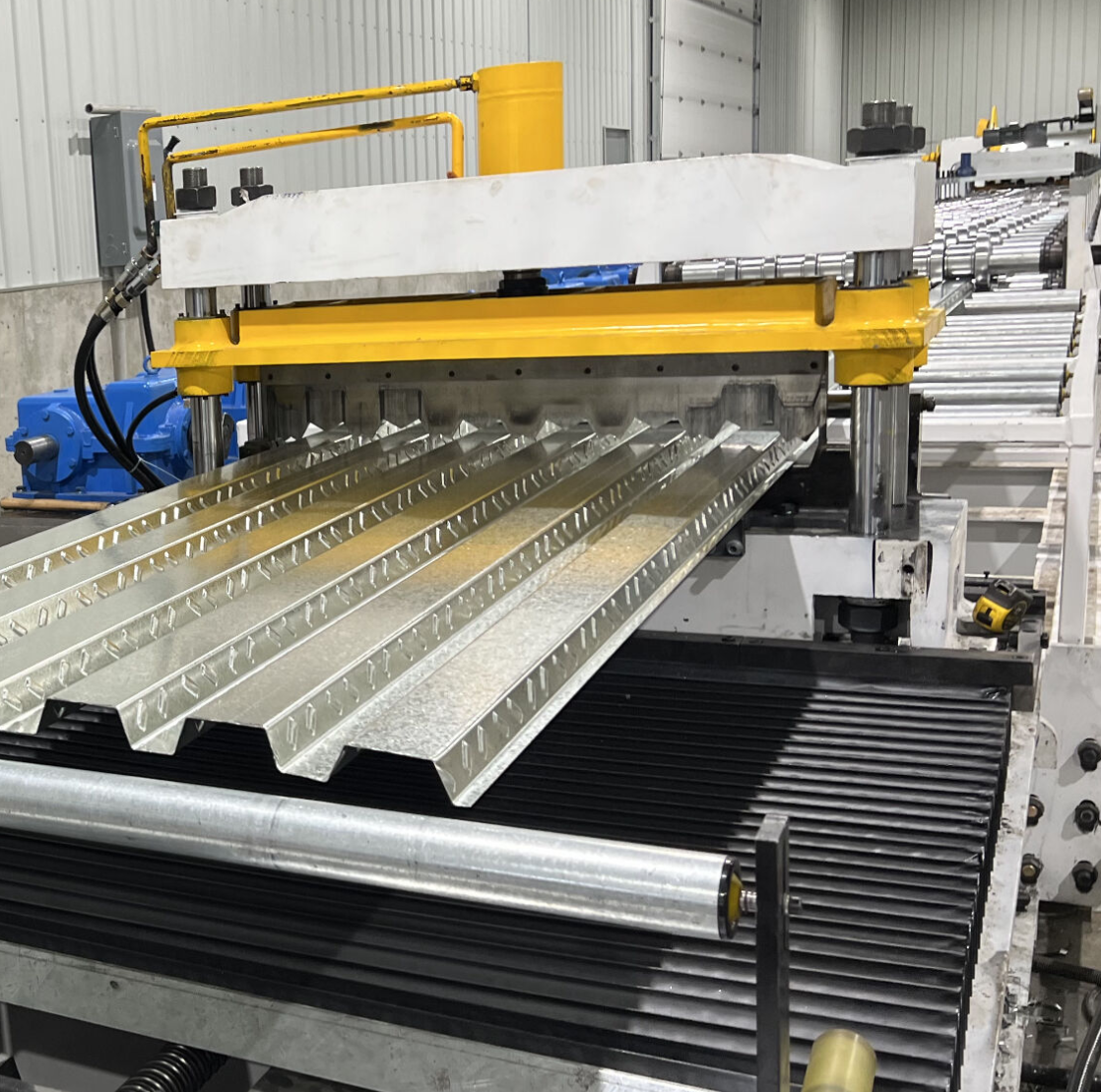

4.5" Cellular Metal Roof Deck Roll Forming Machine – Connecticut, USA

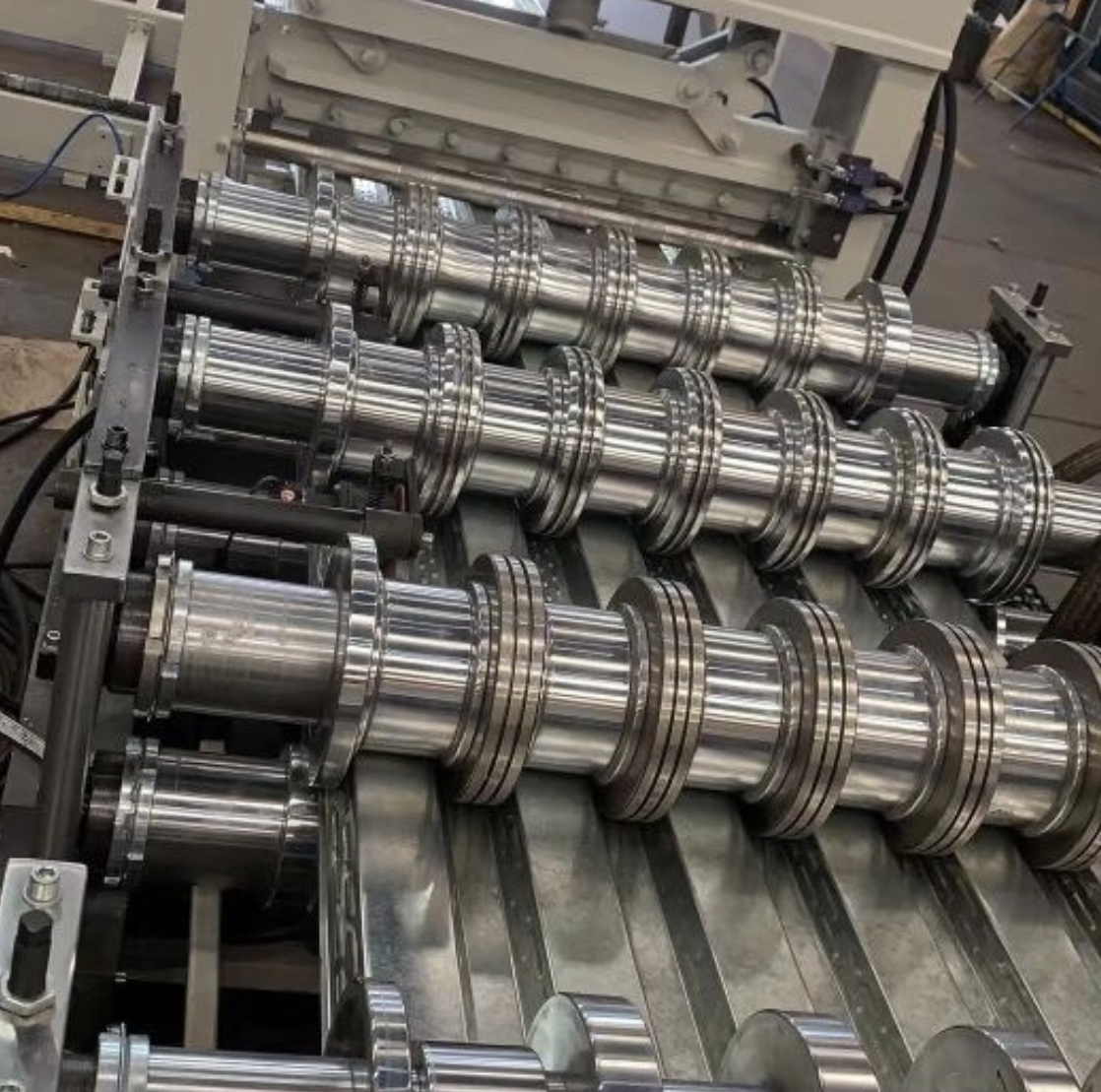

The 4.5" Cellular Metal Roof Deck Roll Forming Machine available in Connecticut, USA, is a high-capacity, precision-built roll forming machine engineered for producing structural metal roof decking used in commercial and industrial construction. This powerful equipment is designed to manufacture 4.5-inch deep cellular metal roof deck profiles with consistency, strength, and efficiency—meeting the needs of contractors, steel fabricators, and construction companies throughout the United States.

Industry Application: This machine is primarily used in the commercial and industrial construction industry, where metal roof decking is required for large-scale building projects such as high-rise offices, manufacturing facilities, warehouses, schools, and hospitals. The 4.5" cellular deck provides structural strength and is ideal for use in buildings where fire ratings, acoustic insulation, and additional utility space (through the cellular cavity) are required.

Key Features & Description:

Machine Specifications:

Customization & Delivery: All machines are custom-built to the customer's specific needs, including profile dimensions, power supply compatibility, and optional features. Machines are manufactured by our trusted international partners and shipped directly to the customer’s facility in Connecticut or other U.S. locations.

Warranty & Support: Each machine is backed by a 1-year warranty from the date of dispatch. Machine Matcher also provides ongoing maintenance, repair, setup, and adjustment services to ensure the machine performs reliably throughout its lifespan.

Contact & Ordering: To receive the most accurate quote tailored to your needs, please provide profile drawings, desired specifications, or application details to: [email protected]

Frequently Asked Questions (FAQs)

Q1: What material gauges can this machine process?

A: The machine can handle steel from 18 gauge to 22 gauge, ideal for structural roofing applications.

Q2: Is it possible to produce other profiles besides the 4.5” cellular deck?

A: Yes. The machine can also produce B deck, N deck, composite deck, and steel form deck. We also offer machines for custom profiles.

Q3: What is the power requirement for installation in the USA?

A: The machine is designed for 480V, 3-phase, 60Hz, which is standard for industrial facilities in the U.S.

Q4: Is the machine made in the USA?

A: The machine is manufactured by our global partners and shipped directly to your facility in Connecticut or other U.S. states.

Q5: How long is the machine?

A: The total footprint of the machine is approximately 85 feet.

Q6: What kind of cutting system does it use?

A: It comes with a Pre-Flying Shear, enabling high-speed cutting without stopping the line.

Q7: What services are available after purchase?

A: Machine Matcher provides setup, maintenance, repair, and adjustment services, ensuring you get the most out of your investment.

Q8: Do you provide auto stackers or material handling equipment?

A: Yes, we offer auto stackers, coil cars, and uncoilers as optional add-ons to streamline production.

About Machine Matcher:

Machine Matcher supplies customers worldwide with a complete line of roll forming machines, including metal roof panel machines, metal flashing machines, purlin machines, trim machines, slitting lines, metal tile machines, and coil handling systems. We also provide support services such as installation, maintenance, and customization to meet your project needs.

Let us help you match the right machine for your metal forming business. For inquiries or to request a quote, email [email protected].

Copyright 2026 © Machine Matcher.