To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

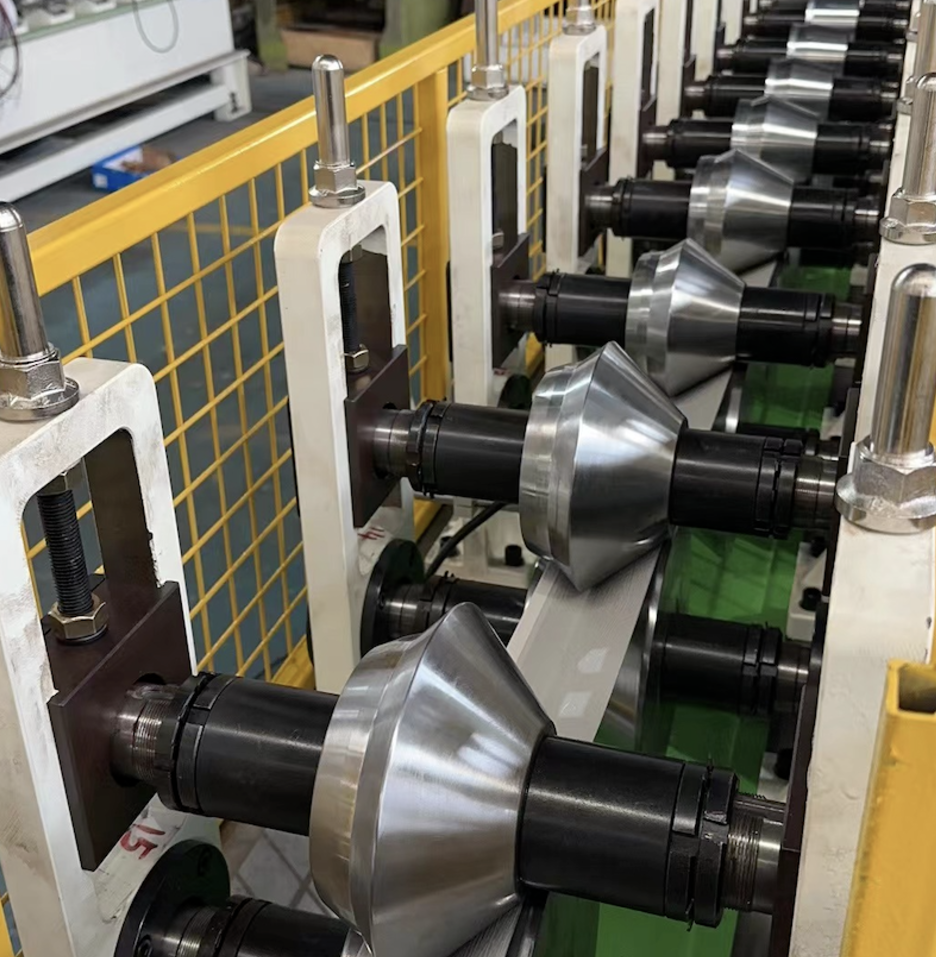

The 90-degree drip edge cold roll forming machine is a high-performance industrial tool designed to produce precise drip edge profiles used in roofing and construction. The machine is engineered to shape metal coils into a 90-degree drip edge profile with consistent accuracy, catering to the demands of roofing manufacturers, contractors, and metal fabricators. Its advanced automation and robust construction make it ideal for large-scale production while maintaining superior quality standards.

1. What materials can the 90-degree drip edge roll forming machine process?

The machine can process galvanized steel, aluminum, copper, and other coated steel materials with a thickness range of 0.3-0.8 mm.

2. Is this machine suitable for Florida’s construction industry?

Yes, the machine is ideal for Florida’s climate as it produces corrosion-resistant drip edges, essential for buildings facing high humidity and frequent rainfall.

3. Can the machine be customized for specific profiles?

Absolutely. The machine supports customization for different widths, heights, and material specifications to meet unique project requirements.

4. What are the energy requirements for this machine?

The machine operates on a standard industrial power supply of 380V, 3-phase, 50/60Hz. However, it can be configured for 220V if required.

5. How easy is the machine to operate?

The machine is user-friendly with a touchscreen PLC system that simplifies setup and operation. Training and manuals are also provided.

6. What kind of maintenance does the machine require?

Routine maintenance includes lubrication of moving parts, inspection of the hydraulic system, and periodic checks of the cutting blades and rollers.

7. Can the machine be used for high-volume production?

Yes, its durable design and high-speed production capability make it perfect for large-scale manufacturing.

8. Are there warranties and after-sales support?

Most suppliers offer a one-year warranty and lifetime technical support. Always confirm with your vendor.

9. How much space is required to install the machine?

The machine typically requires a workspace of 10m x 3m. Ensure enough clearance for material feeding and finished profile stacking.

10. How is the machine delivered to Florida?

The machine is shipped in a standard container, fully secured and tested. Installation and training services can be arranged upon delivery.

Copyright 2026 © Machine Matcher.