To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

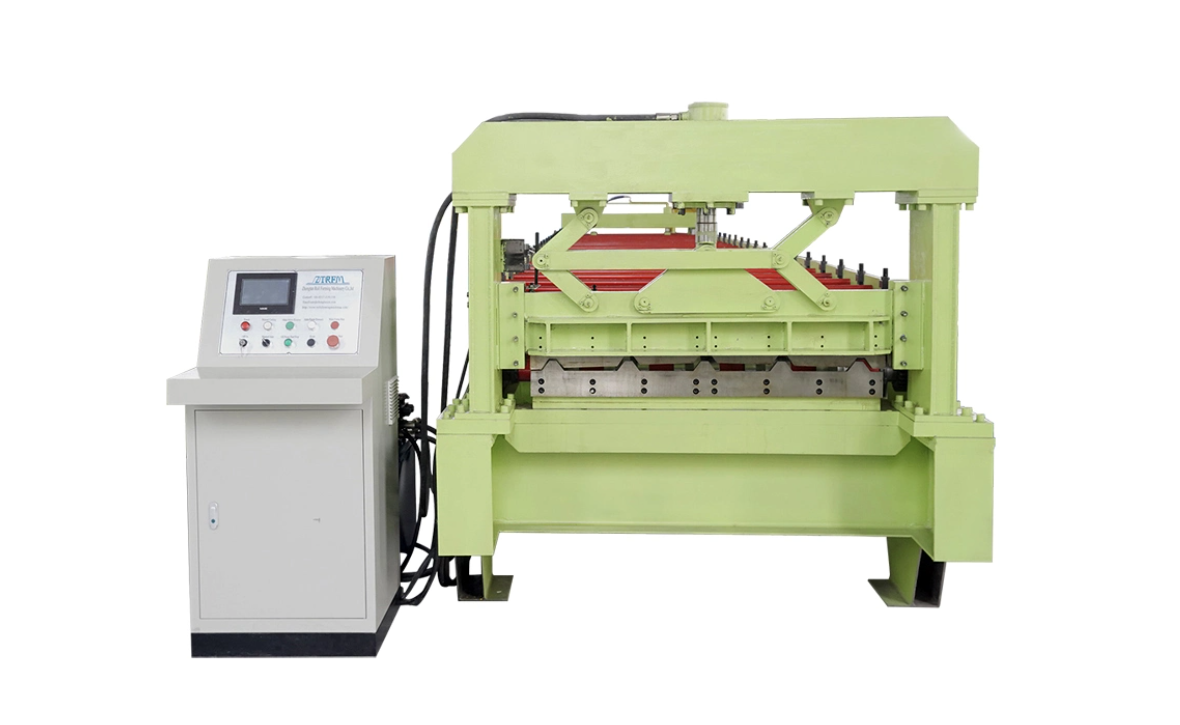

The AG Classic Rib Roll Forming Machine offers the versatility to handle a wide range of materials and project specifications, making it ideal for steel erectors and roofing contractors who need to produce high-quality roofing panels efficiently.

The AG Classic Rib Roll Forming Machine is designed to produce classic ribbed panels, commonly used in agricultural, residential, and commercial roofing applications. This machine delivers high-quality, precision-formed metal roofing panels with enhanced durability and weather resistance.

The AG Classic Rib Roll Forming Machine provides a reliable solution for contractors and manufacturers involved in roofing projects, ensuring high productivity with minimal maintenance.

Copyright 2026 © Machine Matcher.