To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

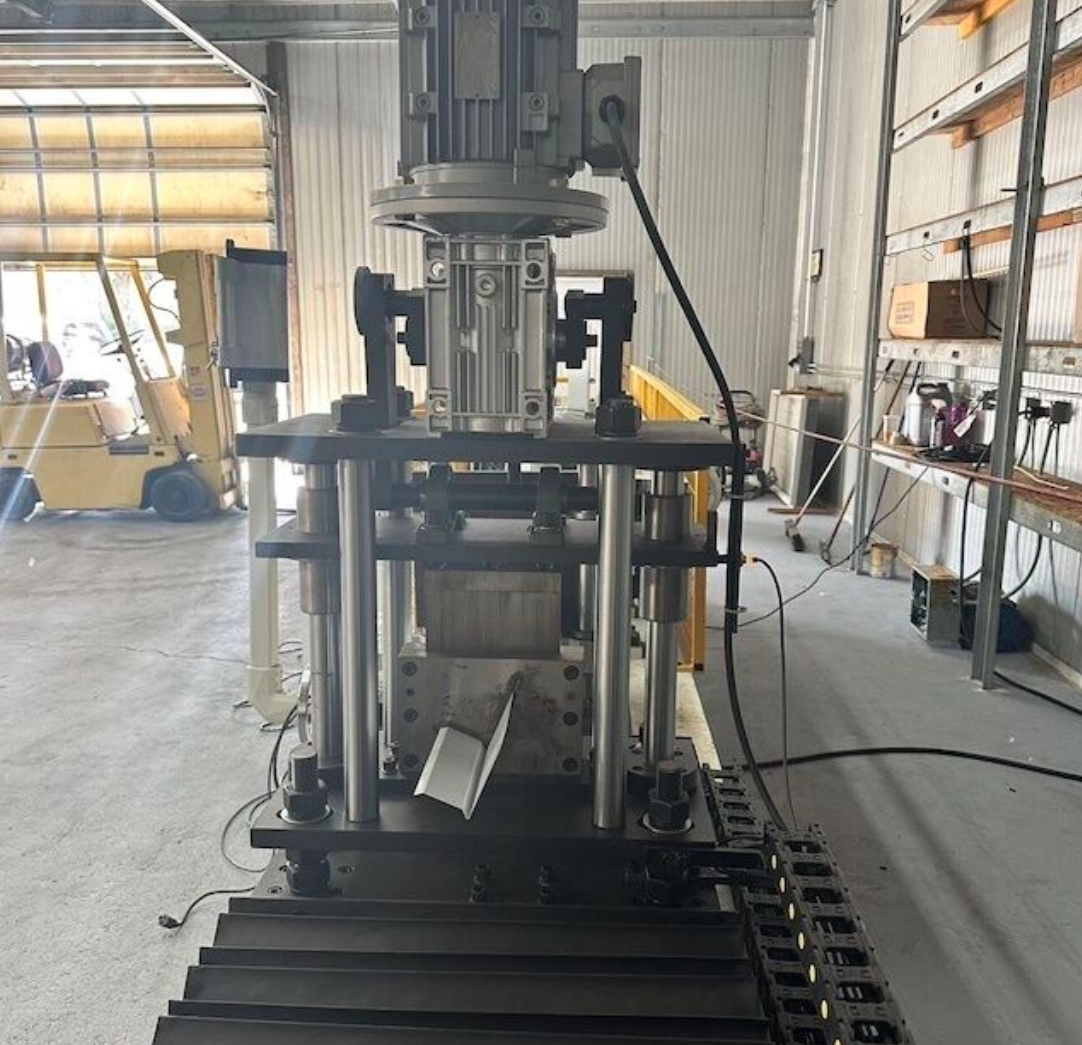

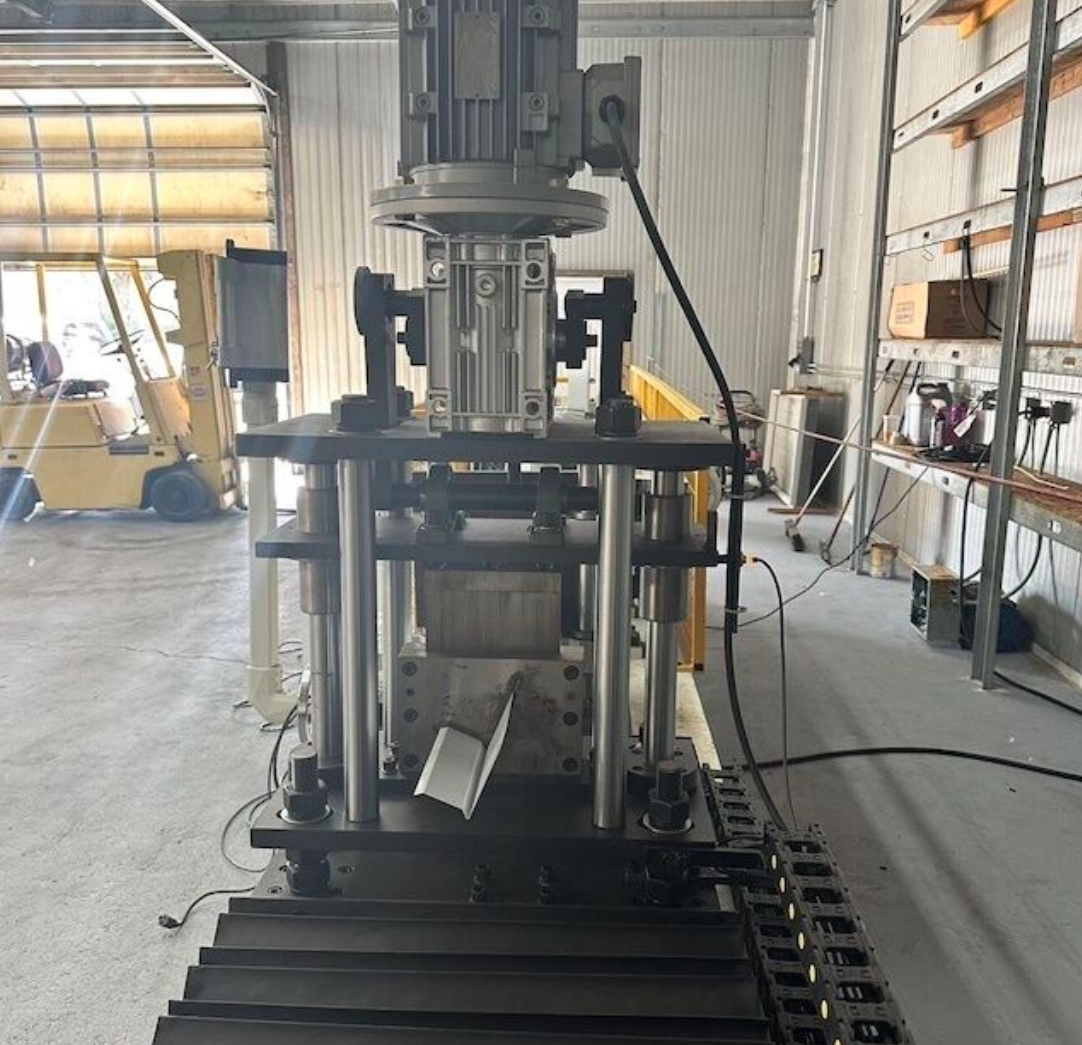

The Aluminum Drip Edge Roll Forming Machine is a high-performance, precision-engineered solution designed to meet the needs of roofing and construction businesses in Alabama, USA. Known for its durability and efficiency, this machine is capable of producing a wide range of drip edge profiles to suit various applications. Whether you need standard or custom profiles, this machine delivers consistent quality with every run, ensuring your projects are completed on time and to specification.

The Aluminum Drip Edge Roll Forming Machine is built to deliver precision with every profile it forms. With a production speed of 80 feet per minute, this machine is ideal for manufacturers and contractors who need efficiency without compromising quality. The 10-stand design ensures that each profile is formed accurately and consistently, maintaining the integrity and dimensions of the drip edges.

This machine supports a wide range of profiles, including C5, C6, F4, 90 Degree, D Style, and FHA, with the flexibility to create custom profiles based on specific project requirements. This versatility makes it an excellent choice for contractors handling various roofing projects.

Equipped with a 240V, three-phase, 60 Hz power system, this roll forming machine is designed to handle continuous production with minimal downtime. The electric shear cutting system provides clean, precise cuts for every profile, reducing material waste and enhancing overall productivity.

The machine’s footprint of 18 ft x 3 ft x 5 ft allows for easy integration into most production spaces, making it suitable for both large-scale manufacturers and smaller workshops. With a weight of 2,500 lbs, it remains stable during high-speed operations.

We offer a range of optional extras to enhance the performance and versatility of the Aluminum Drip Edge Roll Forming Machine:

These options can be tailored to fit your production requirements, ensuring you get the most out of your investment.

The demand for high-quality drip edges in Alabama’s roofing industry is significant, driven by the state’s variable climate conditions. This machine’s ability to produce durable and weather-resistant aluminum profiles makes it a valuable asset for manufacturers and contractors across the state.

Common applications include:

Pricing for the Aluminum Drip Edge Roll Forming Machine is determined based on the optional extras and customization requirements you select. To receive a tailored quote that meets your specific needs, please contact us directly.

1. What types of profiles can this machine produce?

The machine can produce C5, C6, F4, 90 Degree, D Style, FHA, and custom profiles based on your requirements.

2. How fast can the machine produce drip edges?

The machine operates at a speed of 80 feet per minute, ensuring high productivity for both large and small-scale projects.

3. Is it possible to customize the machine based on specific needs?

Yes, we offer a range of optional extras such as remote PLC systems, stackers, and custom profile capabilities to fit your production needs.

4. What power requirements does this machine have?

The machine operates on a 240V, three-phase, 60 Hz power supply, which is standard for industrial-grade equipment.

5. How can I get a price quote for this machine?

Pricing is based on the optional extras and customization you require. Please contact us with your specifications to receive a detailed quote.

6. Is technical support available for this machine?

Yes, we provide comprehensive technical support and maintenance services to ensure your machine operates smoothly.

7. Can the machine handle other materials besides aluminum?

While it is optimized for aluminum, the machine can be customized to handle other materials upon request. Contact us for more details.

For more information or to request a quote, please contact us today!

Copyright 2026 © Machine Matcher.