To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

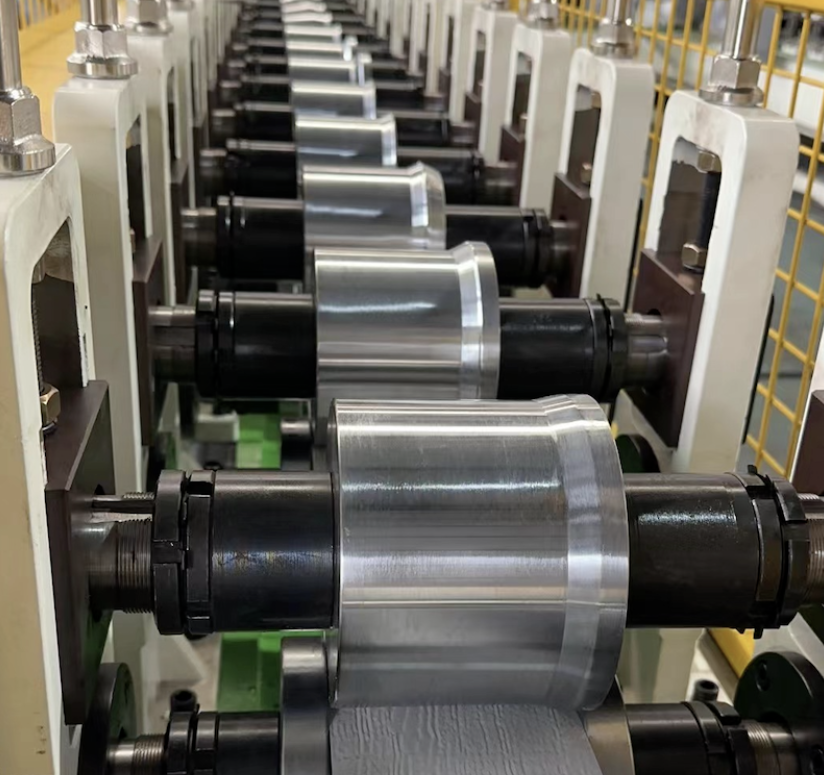

The aluminum drip edge roll forming machine is specifically designed to manufacture high-quality drip edge profiles used for roofing applications. These profiles play a vital role in directing water away from roofs, enhancing the durability and appearance of roofing systems. The machine offers precision and efficiency, enabling manufacturers to produce drip edges in large volumes with minimal waste.

Equipped with advanced automation systems, the aluminum drip edge roll forming machine is ideal for small to large-scale manufacturing units in the USA. The machine is robust, easy to operate, and tailored for consistent performance with various aluminum grades and thicknesses.

Q: What are the advantages of using aluminum for drip edges?

A: Aluminum is lightweight, corrosion-resistant, and easy to work with, making it a durable and cost-effective choice for drip edges.

Q: Can this machine handle materials other than aluminum?

A: Yes, the machine can be customized to handle materials like galvanized steel and copper, but adjustments to rollers and settings may be required.

Q: How can I ensure consistent profile quality?

A: Regular maintenance, proper calibration, and using high-quality aluminum coils will ensure consistent profile quality.

Q: What is the expected lifespan of the machine?

A: With proper maintenance, the machine can last 10–15 years or more, depending on usage intensity.

Q: Is operator training included with the purchase?

A: Many manufacturers provide operator training as part of the package or at an additional cost.

Q: What is the estimated production capacity?

A: The production capacity depends on the machine's speed and the length of the drip edge but typically ranges between 8,000–12,000 feet per day.

Q: Can the machine be relocated easily?

A: Yes, the machine is designed to be portable within the production facility, provided you have the right handling equipment.

Q: Are spare parts readily available in the USA?

A: Most suppliers stock spare parts locally or can arrange quick shipments from their warehouses.

Copyright 2026 © Machine Matcher.