To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Aluminum metal roofing roll forming machines are designed to create high-quality, durable, and aesthetically appealing aluminum roofing panels. These machines are ideal for the U.S. market, where aluminum roofs are favored for their lightweight, corrosion resistance, and energy efficiency. Industries ranging from residential to commercial and agricultural sectors use these machines to produce panels that suit the diverse climatic conditions across the United States.

The aluminum metal roofing roll forming machine automates the production of roofing panels from aluminum coils. It offers precision-engineered solutions that ensure consistency in profiles, sizes, and finishes.

Key Features:

The machine can produce various profiles, including standing seam panels, corrugated sheets, and other custom designs suitable for different roofing applications.

Yes, while optimized for aluminum, the machine can process other materials like galvanized steel, copper, or pre-painted sheets, with slight adjustments.

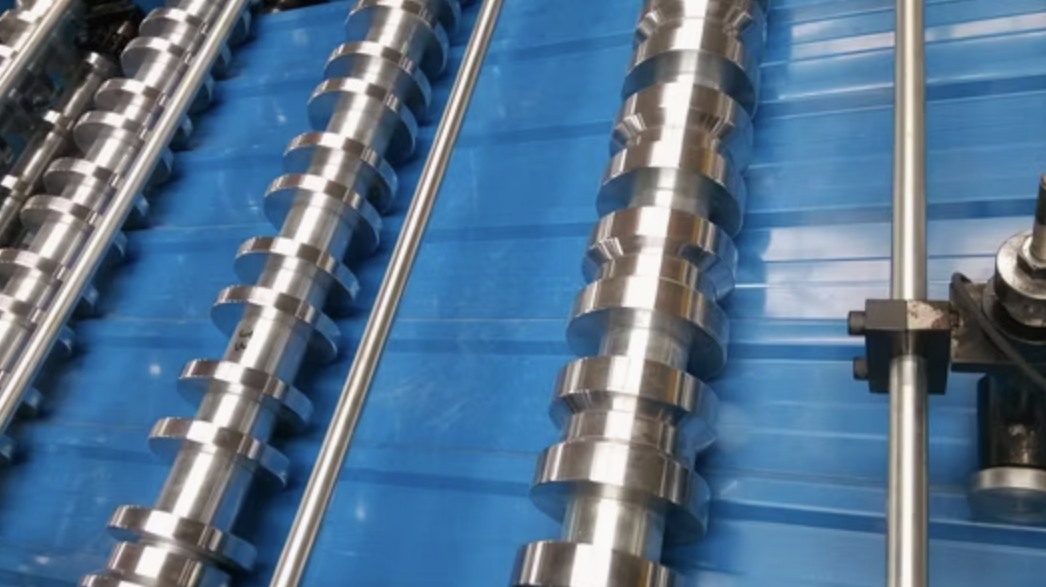

The machine features precision-engineered rollers, servo motors, and an advanced PLC system that ensures uniformity in every profile.

Yes, the machine is customizable to work with standard U.S. power specifications (220V/380V, 3-phase, 60 Hz).

The machine is user-friendly, equipped with a touchscreen interface and intuitive controls. Training is usually minimal, and remote assistance can be provided.

Regular maintenance includes lubrication of moving parts, periodic inspection of rollers and cutting blades, and software updates for the PLC system.

Absolutely. Manufacturers offer customization options, including unique profile designs, additional features, and enhanced automation.

The machine typically produces at 15–30 meters per minute, depending on the material and profile. Speed can be adjusted via the control panel.

The machine includes safety guards, emergency stop buttons, and enclosed cutting areas to minimize the risk of accidents.

Yes, you can include options like stackers, coil car tippers, embossing rollers, or even custom feeders.

Copyright 2026 © Machine Matcher.