To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

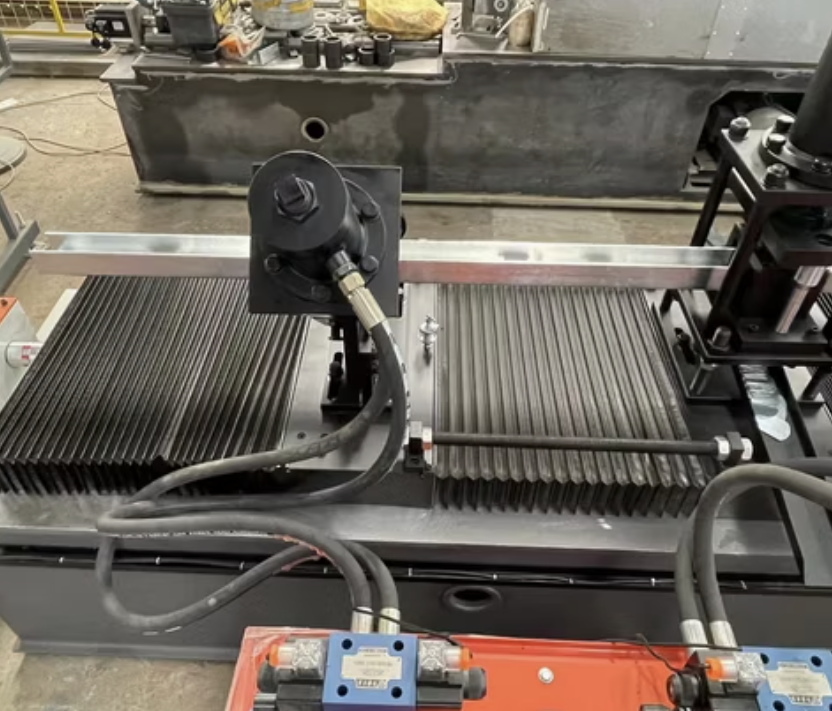

Beam roll forming machines are advanced manufacturing systems designed to produce structural beams used in construction, industrial, and engineering applications. These machines are engineered for precision, durability, and high production efficiency, meeting the stringent demands of modern construction and structural industries. They can produce a variety of beam profiles, including I-beams, H-beams, and other custom profiles.

Here’s a detailed breakdown of the specifications for a typical beam roll forming machine:

A: Beam roll forming machines can produce various profiles, including I-beams, H-beams, U-beams, C-channels, and Z-beams. Custom profiles can also be created based on specific design requirements.

A: The standard production speed ranges from 15 to 30 meters per minute. However, the speed can vary depending on the profile complexity and material type.

A: Yes, beam roll forming machines are designed to process materials up to 10 mm thick and with yield strengths up to 450 MPa, making them suitable for heavy-duty applications.

A: Safety guards, emergency stop buttons, and overload protection systems are standard features to ensure operator safety.

A: Absolutely. Machines can be configured for U.S. power requirements, typically 220V/440V at 60 Hz.

A: The space requirement varies depending on the machine size and configuration. A typical machine with 20 roller stations may require 20–30 feet in length and 5–8 feet in width.

A: Regular maintenance includes lubrication of moving parts, inspection of rollers for wear, and periodic checks of the PLC system and hydraulic components.

A: The construction, infrastructure, and industrial equipment sectors are the primary users in the U.S. market.

A: You can provide your required profile design, material specifications, and production volume to receive a customized quote.

Beam roll forming machines are integral to the structural and construction industries, providing efficiency, precision, and flexibility for manufacturing high-quality beams. Their robust design, advanced automation, and customization options make them a valuable asset for companies across the USA. Whether you're involved in large-scale infrastructure projects or specialized engineering applications, these machines are tailored to meet your needs.

Copyright 2026 © Machine Matcher.