To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

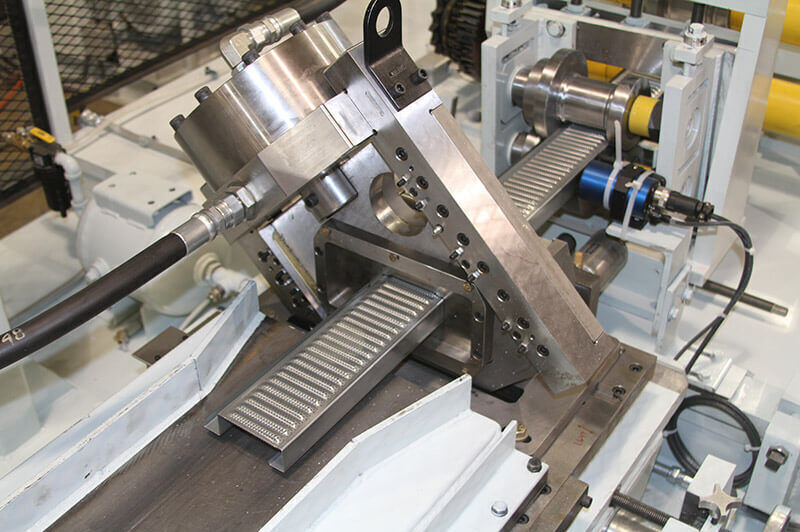

A Grain Bin Floor Roll Forming Machine is a specialized piece of equipment designed to produce corrugated panels used in grain bins or silos. These panels are crucial for grain storage facilities, providing a durable, ventilated floor to ensure proper aeration and prevent spoilage of stored grains.

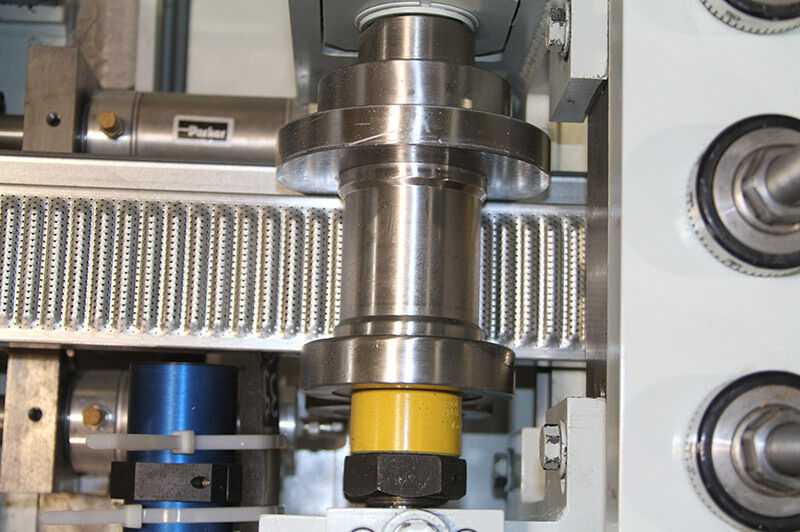

The Grain Bin Floor Roll Forming Machine is engineered to fabricate high-strength, precise corrugated floor panels. These panels are typically perforated or have airflow gaps for effective grain aeration. The machine operates with advanced automation, ensuring consistency and accuracy in production. It is suitable for manufacturing panels from galvanized steel or other corrosion-resistant materials.

This roll forming system includes several stages: feeding, roll forming, punching (optional), cutting, and stacking. The machine is equipped with user-friendly controls, ensuring efficient operation even for less experienced operators.

1. What materials can the Grain Bin Floor Roll Forming Machine process?

The machine can process galvanized steel, stainless steel, and aluminum, with thicknesses ranging from 0.5 mm to 1.5 mm.

2. Is it possible to customize the perforation patterns?

Yes, the hydraulic punching system allows for customizable perforation patterns, controlled through the PLC system.

3. What is the production speed of the machine?

The standard production speed is 15–25 m/min, with high-speed options available up to 40 m/min.

4. How is the machine controlled?

The machine is controlled via a PLC system with a touchscreen interface, providing easy operation and real-time monitoring.

5. Can the machine operate on different power supplies?

Yes, the power system can be customized to meet regional requirements, such as 380V/50Hz or other standards.

6. What safety features does the machine have?

The machine includes safety guards, emergency stop buttons, and optional enclosures to ensure operator safety.

7. How long does it take to set up the machine?

Initial setup and calibration typically take 2–3 days, depending on the configuration and site conditions.

Copyright 2026 © Machine Matcher.