To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

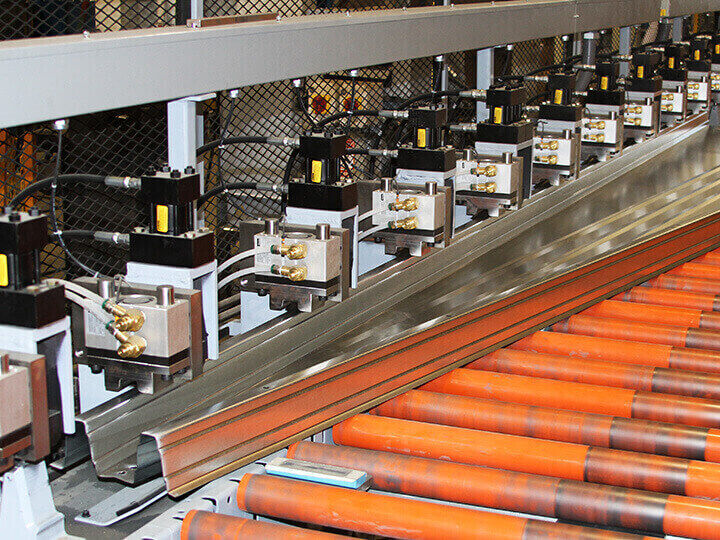

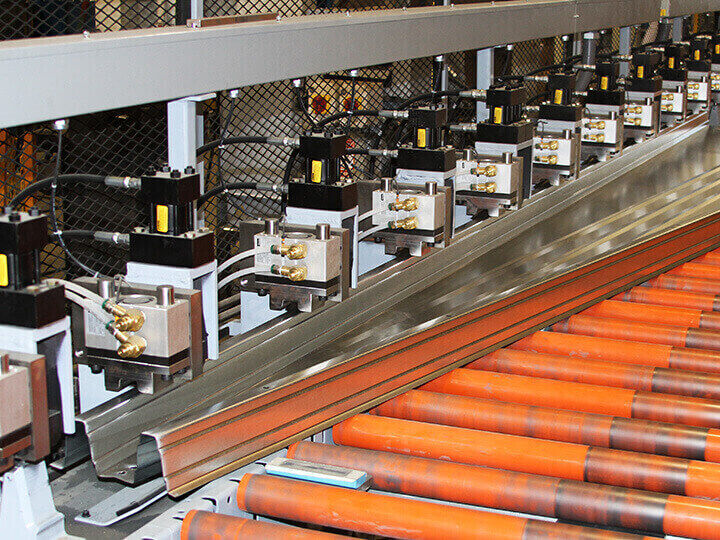

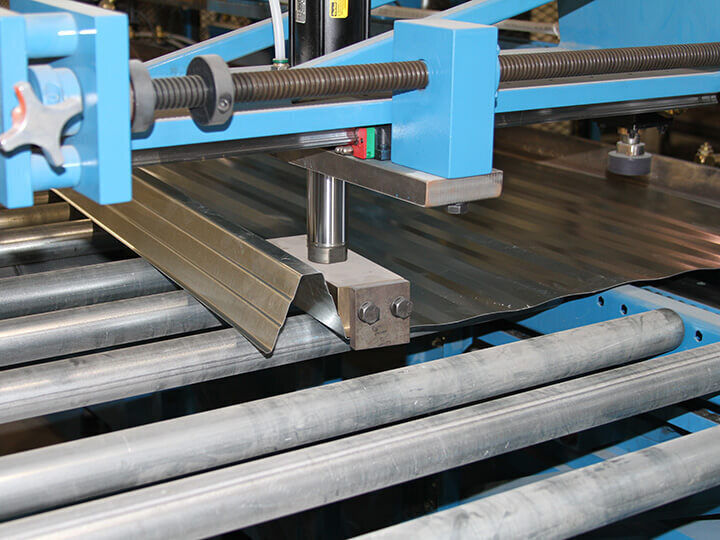

The Grain Bin Roof Roll Forming Machine is a specialized equipment designed for the production of roof panels used in grain bins. These panels are essential for agricultural and storage applications, ensuring durability, precision, and optimal protection of stored materials. The machine is engineered to meet high standards of efficiency and quality, catering to the specific needs of the agricultural industry in the USA.

The Grain Bin Roof Roll Forming Machine is a robust and highly efficient system capable of producing high-quality grain bin roof panels with precision. This machine offers advanced features such as automated controls, customizable panel dimensions, and optional add-ons for enhanced productivity. It is designed to work with a variety of materials, providing flexibility and catering to diverse agricultural storage needs.

Key Features:

Here are the detailed technical specifications of the Grain Bin Roof Roll Forming Machine:

Q1: What materials can be used with the Grain Bin Roof Roll Forming Machine? A1: The machine is compatible with galvanized steel, aluminum, and coated steel, with material thickness ranging from 0.5 mm to 1.2 mm.

Q2: How customizable are the roof panel profiles? A2: The machine allows for full customization of panel widths and lengths to match different grain bin designs.

Q3: What is the typical production speed? A3: The machine operates at a speed of 10-15 meters per minute, depending on the material and profile specifications.

Q4: Can the machine be monitored remotely? A4: Yes, with the optional remote PLC system, the machine can be monitored and controlled remotely for enhanced convenience.

Q5: What safety features are included? A5: The machine includes safety guards, emergency stop buttons, and overload protection systems to ensure operator safety.

Q6: How is the machine delivered and installed? A6: The machine is shipped in a secure container, with on-site installation and training provided by technical experts.

Q7: Is it suitable for small-scale operations? A7: While primarily designed for industrial use, the machine can be adjusted for smaller operations if required.

Copyright 2026 © Machine Matcher.