To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

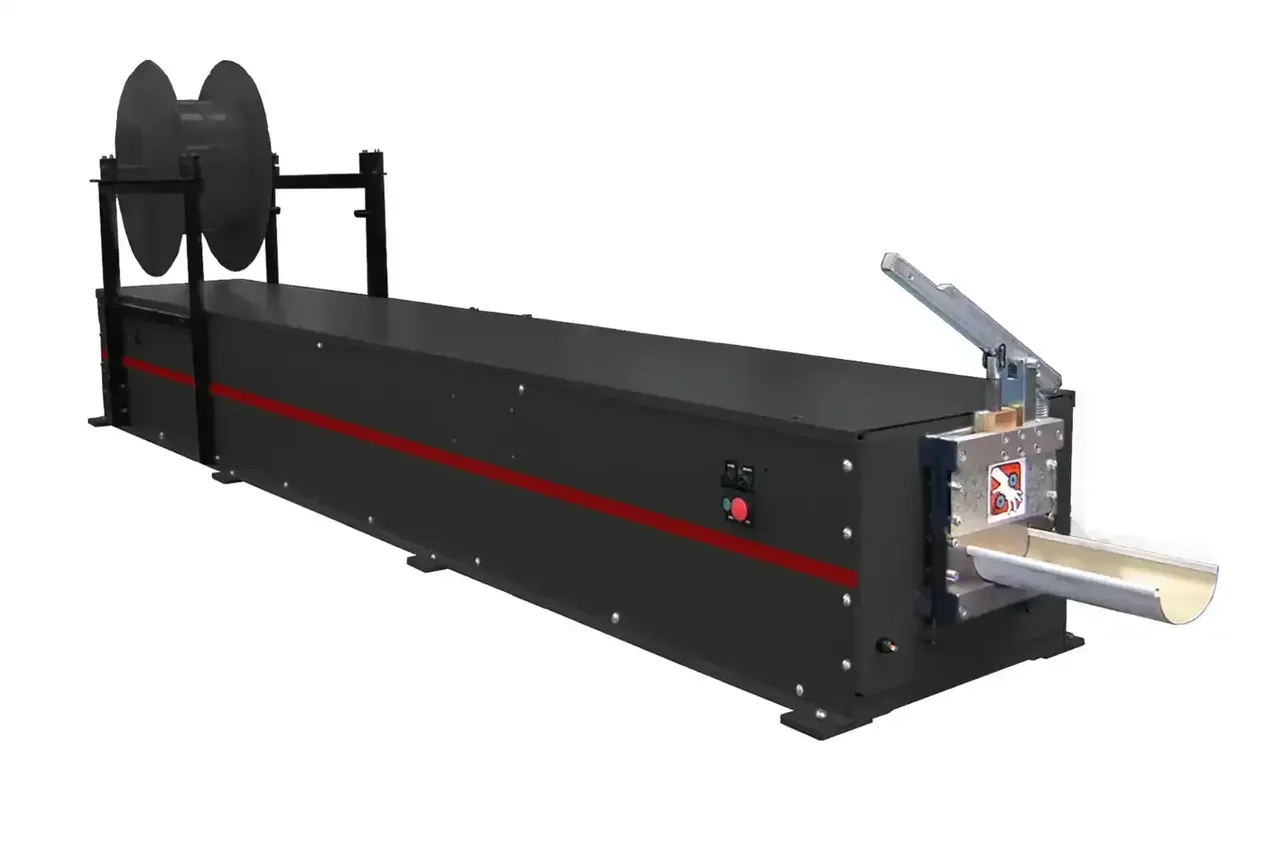

A gutter roll forming machine transforms flat metal sheets into finished gutter profiles through a series of rollers. The process is fully automated, ensuring consistent quality and high efficiency. The machine supports various materials such as aluminum, galvanized steel, copper, and stainless steel, which are widely used in the US due to their durability and corrosion resistance.

| Parameter | Details |

|---|---|

| Roller Material | GCr15 steel with hard chrome plating |

| Frame Construction | Heavy-duty steel |

| Control System | PLC control with touch screen interface |

| Drive System | Chain or gearbox-driven rollers |

| Power Supply | 220V/380V/440V, 50Hz/60Hz |

| Motor | 5-10 HP depending on machine capacity |

| Cutting System | Hydraulic cutting with high-precision steel blades |

| Machine Speed | 15-30 meters per minute |

| Material Thickness | 0.3mm - 1.2mm |

| Profiles Supported | K-style, half-round, box gutters |

| Optional Features | Decoilers, automatic stackers, embossing, punching |

| Dimensions | 7m (L) x 1.5m (W) x 1.4m (H) |

| Weight | 3,500 - 5,000 kg depending on configuration |

The most popular profiles include:

The machine is compatible with aluminum, galvanized steel, copper, stainless steel, and pre-painted steel, which are common in the US market.

The machine can be customized to produce specific profiles, sizes, and materials as per customer requirements. Additional features like embossing, punching, or curved gutter production can also be integrated.

Production speed ranges from 15 to 30 meters per minute, depending on the material thickness and profile complexity.

The machine is user-friendly with a PLC touch screen interface for easy operation. Regular maintenance includes lubrication, roller cleaning, and periodic inspections of the hydraulic and cutting systems.

Yes, optional accessories like decoilers, automatic stackers, and leveling systems can be added for enhanced efficiency.

Prices vary based on specifications and customizations but generally range from $25,000 to $100,000.

Yes, machines are typically shipped with detailed setup and installation guides. Many manufacturers also provide on-site installation and training.

Yes, the machine complies with US safety and quality standards, ensuring reliability and efficiency.

Most manufacturers provide after-sales support, including training, spare parts supply, and technical assistance via phone or online platforms.

Copyright 2026 © Machine Matcher.