To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

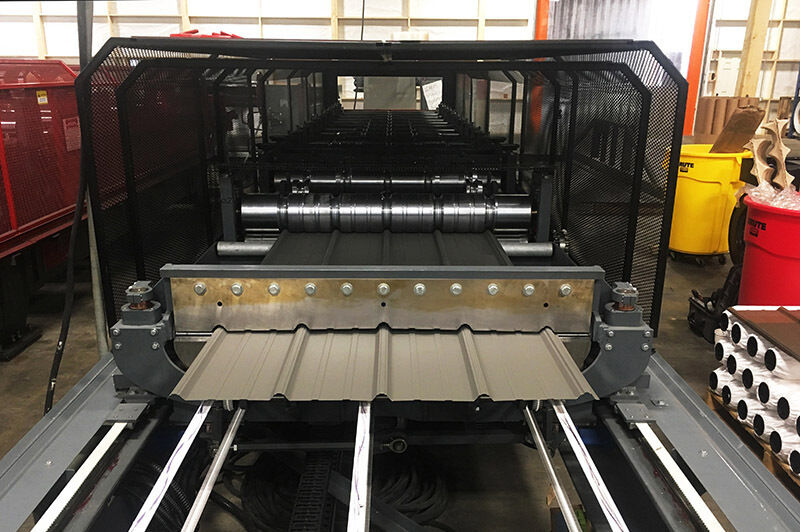

The Roof Panel with Flying Shear Roll Forming Machine is a state-of-the-art solution for producing high-quality roof panels with precise dimensions and smooth edges. The integration of a flying shear system ensures continuous operation without the need to stop for cutting, which significantly increases production speed and efficiency. This machine is ideal for manufacturers who prioritize high throughput and consistent panel quality.

Designed for various profile designs, including corrugated, trapezoidal, and other roofing shapes, this roll forming machine accommodates a wide range of material gauges and panel lengths. The advanced PLC control system allows easy customization and automated operation, making it user-friendly and efficient.

The setup of the Roof Panel with Flying Shear Roll Forming Machine involves:

Q1: What is the benefit of a flying shear system compared to a conventional cutting system?

A: A flying shear system cuts panels while the machine is still running, reducing downtime and increasing production efficiency.

Q2: Can this machine produce multiple profiles?

A: Yes, the machine can be configured to produce various profiles, but switching between profiles may require additional tooling or adjustments.

Q3: What materials are compatible with this machine?

A: The machine works with galvanized steel, pre-painted steel, aluminum, and other coated materials within the specified thickness range.

Q4: How accurate is the cutting with the flying shear?

A: The flying shear system ensures high cutting accuracy, typically within ±1mm.

Q5: What is the average lifespan of the rollers?

A: With proper maintenance, the rollers can last for several years, even in high-production environments.

Q6: Is the machine suitable for small-scale operations?

A: While designed for high production, it can also cater to small-scale operations due to its flexible control system.

Q7: What safety measures are included?

A: The machine is equipped with safety guards, emergency stop buttons, and overload protection to ensure operator safety.

Q8: Can the machine be integrated into an existing production line?

A: Yes, it can be integrated with other equipment such as uncoilers, stackers, and recoilers for a seamless production line.

Copyright 2026 © Machine Matcher.