To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

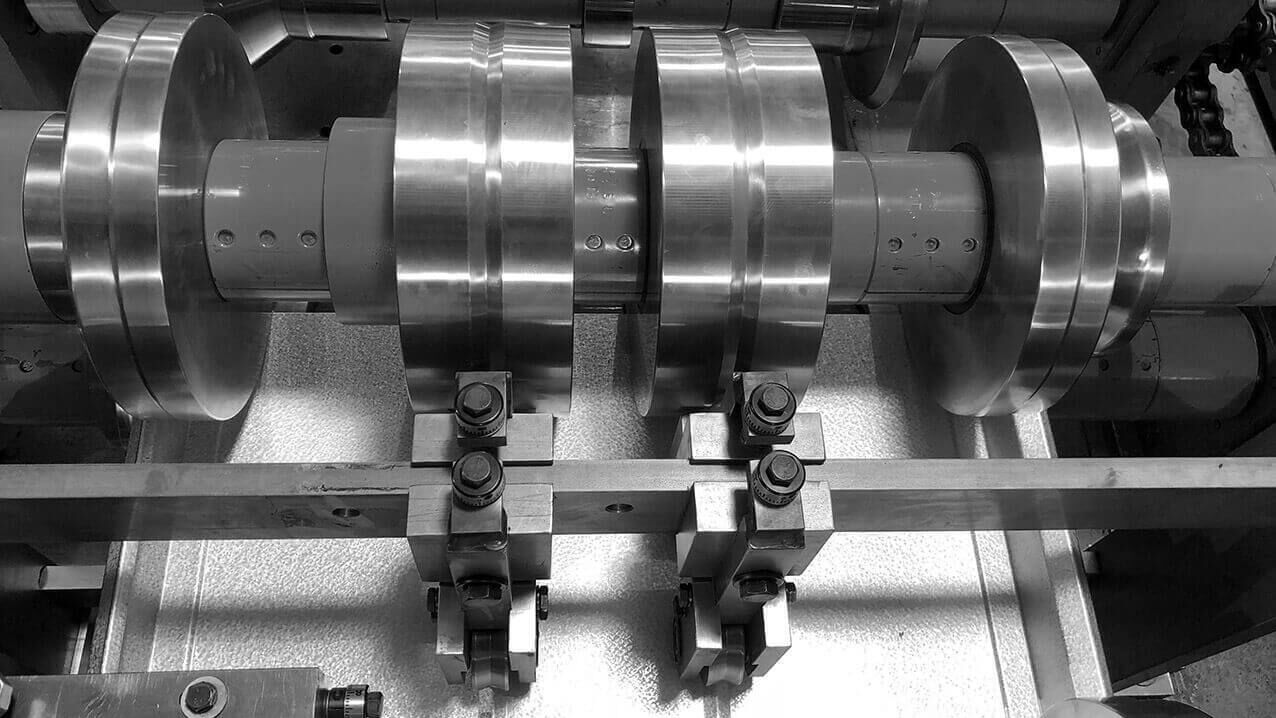

A Standing Seam Roll Forming Machine is a specialized equipment designed to produce standing seam metal panels used in roofing and cladding applications. These panels interlock seamlessly, providing superior waterproofing and aesthetic appeal. The machine transforms metal coils into precise profiles with a consistent, high-quality finish, catering to the demands of the construction and metal roofing industries in the USA.

Standing seam panels are highly valued for their durability, modern appearance, and ability to withstand harsh weather conditions, making them popular in residential, commercial, and industrial buildings.

Copyright 2026 © Machine Matcher.