To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

C channel roll forming machines are essential in the construction and industrial sectors, producing precise and durable C-shaped profiles used in framing, support structures, and various metal applications. These machines are efficient, versatile, and tailored to meet the stringent requirements of California’s diverse industries, including construction, automotive, and solar energy systems.

In California, with its booming construction and renewable energy projects, demand for high-quality C channels is on the rise. This blog highlights the machine's features, specifications, benefits, and frequently asked questions to help California-based businesses make informed decisions.

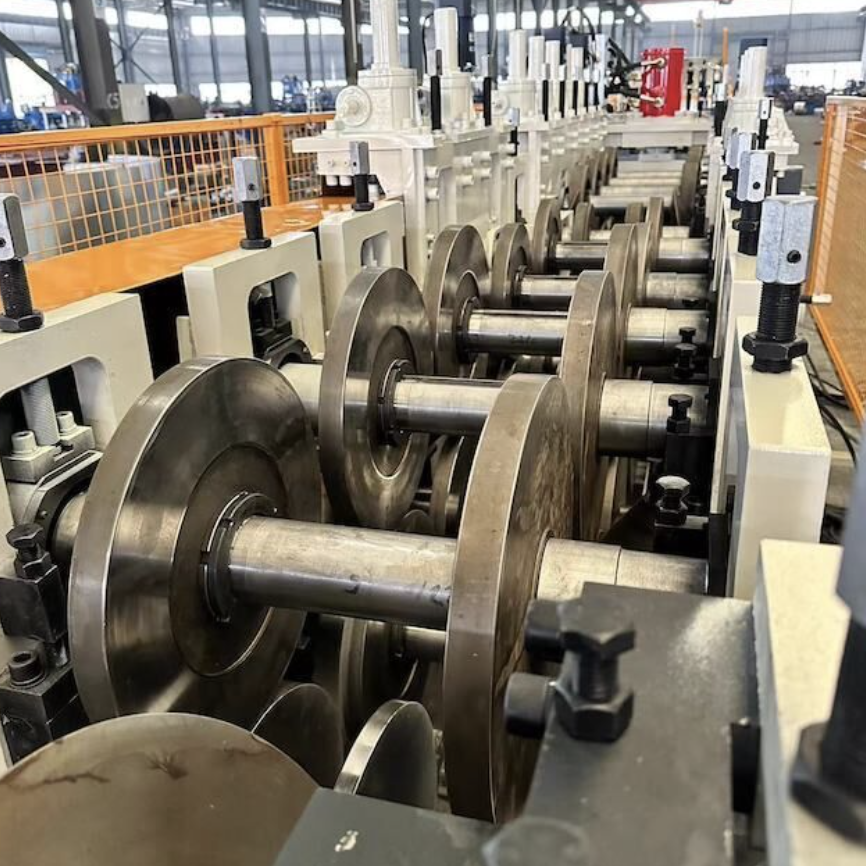

A C channel roll forming machine is designed to produce C-shaped metal channels by continuously bending a metal strip through a series of rollers. These machines are renowned for their high speed, precision, and ability to handle various materials, including galvanized steel, aluminum, and stainless steel.

Key features of the machine include:

Below are the general specifications for a standard C channel roll forming machine. Customizations are available to suit specific requirements:

The machine is delivered ready for assembly and installation. Our technicians provide comprehensive guidance or on-site assistance for California-based clients.

Q1: What types of materials can the machine process?

A: The machine can handle galvanized steel, stainless steel, aluminum, and cold-rolled steel. Material customization is available for specific needs.

Q2: Is the machine compliant with California energy standards?

A: Yes, the machine is optimized for energy efficiency and complies with California's energy regulations.

Q3: Can the machine produce custom C channel sizes?

A: Absolutely! The machine is equipped with adjustable settings to accommodate various widths, heights, and material gauges.

Q4: How long does it take to set up the machine?

A: Initial setup typically takes 1–2 days, including calibration and training for operators.

Q5: Do you offer post-sale support in California?

A: Yes, we provide after-sales support, including maintenance services, spare parts, and technical assistance.

Q6: What is the average lead time for delivery?

A: Standard machines are ready for shipment within 4–6 weeks. Custom machines may require additional time.

Copyright 2026 © Machine Matcher.