To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

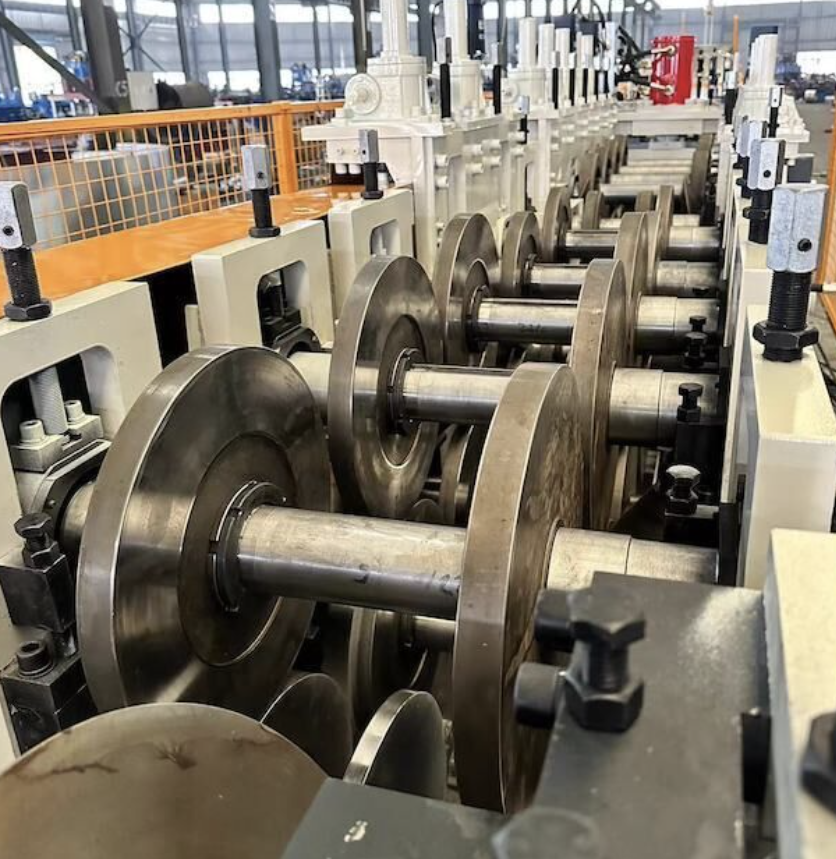

The C channel roll forming machine is a specialized industrial tool designed for the production of high-precision C channel profiles. These channels are widely used in construction, infrastructure, and industrial applications, offering structural support, framing, and reinforcement. The machine transforms metal coils into durable C channels with consistent dimensions, using advanced roll forming technology.

Ideal for industries in Georgia, USA, this machine supports local demands for construction materials, particularly in sectors like residential, commercial, and industrial building projects. Its ability to produce uniform profiles ensures quality and compliance with stringent U.S. standards.

Q1: What industries commonly use C channels in Georgia?

A1: Industries such as construction, solar power, industrial shelving, and transportation use C channels for their durability and structural strength.

Q2: Can the machine produce custom sizes for specific projects?

A2: Yes, the machine can be programmed to produce custom sizes to meet project-specific requirements.

Q3: What is the production capacity of the machine?

A3: Depending on the material thickness and profile size, the machine can produce up to 15-30 meters of C channel per minute.

Q4: Does the machine comply with U.S. safety standards?

A4: Yes, the machine is designed to meet OSHA safety standards and includes safety guards, emergency stops, and enclosures.

Q5: Is financing available for buyers in Georgia?

A5: Financing options are often available through third-party providers or distributors, depending on the machine supplier.

Q6: What is the delivery time for the machine?

A6: Standard delivery time ranges from 4-6 weeks, depending on customization requirements.

Q7: Can the machine handle recycled materials?

A7: Yes, as long as the recycled material meets the specified thickness and strength requirements.

Investing in a C channel roll forming machine for the Georgia market offers businesses an efficient solution for high-quality production. Its robust design, user-friendly operation, and adaptability to local demands make it a vital asset for industries. With customization options, compliance with U.S. standards, and reliable support, this machine stands as a cornerstone for infrastructure development across Georgia.

Copyright 2026 © Machine Matcher.