To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

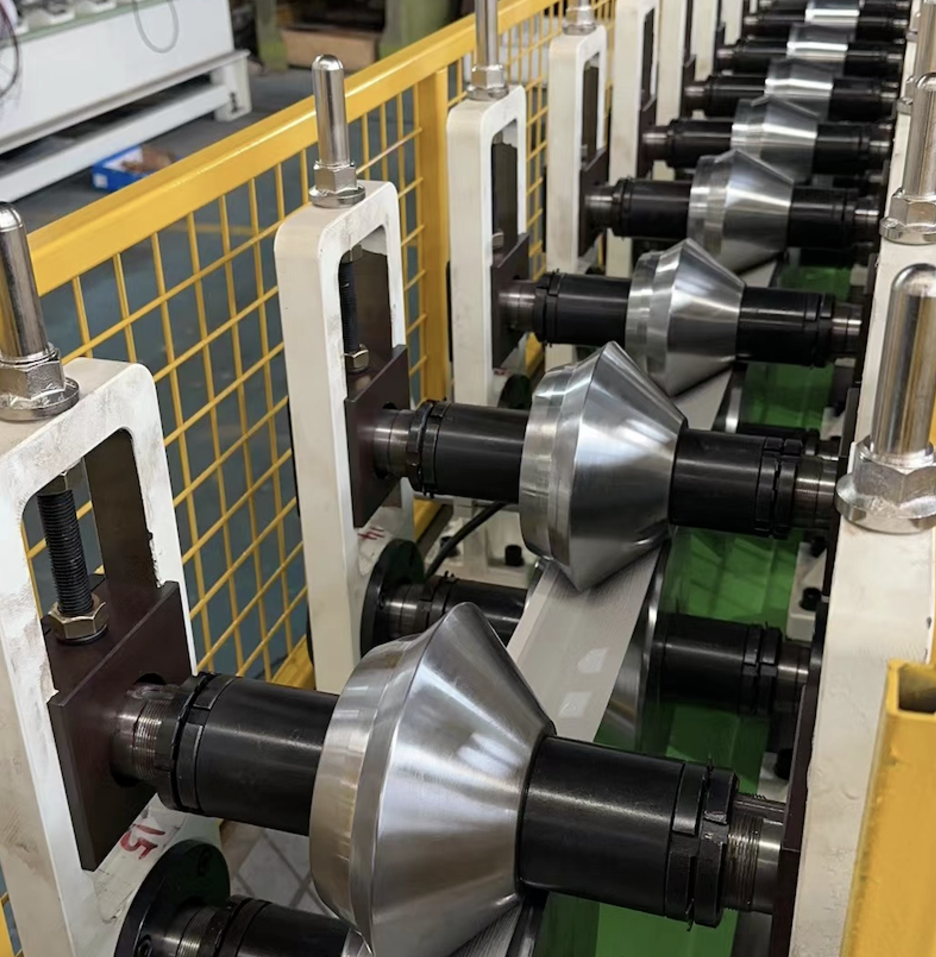

The C6 Drip Edge Cold Roll Forming Machine is a highly specialized piece of equipment designed for the production of C6 drip edge profiles. These profiles are essential components in roofing and siding applications, helping to direct water away from underlying structures and prevent water damage. This machine offers precision, durability, and efficiency, making it a top choice for manufacturers aiming to produce high-quality drip edge products consistently.

Built with cutting-edge technology, the C6 Drip Edge Roll Forming Machine is equipped with advanced automation systems, ensuring minimal manual intervention and reduced errors during operation. Its robust frame and efficient roll-forming stations make it capable of handling various materials while maintaining accuracy and speed.

The machine is designed to handle galvanized steel, aluminum, and copper with thicknesses ranging from 0.3 mm to 0.8 mm.

Yes, the machine can be customized to produce various widths and profile designs according to customer requirements.

The standard production speed is 15-20 meters per minute, with optional upgrades available to achieve up to 30 meters per minute.

The hydraulic cutting system is servo-driven, ensuring a cutting tolerance of ±0.5 mm for precise and clean cuts.

Yes, the machine is equipped with a user-friendly PLC touchscreen interface, allowing operators to set parameters, monitor production, and troubleshoot issues easily.

Safety guards are installed around the forming and cutting stations, and emergency stop buttons are strategically placed for immediate halting of operations in case of an emergency.

The machine is shipped in standard containers and requires professional installation, which can be completed in 1-2 days by trained technicians.

Regular lubrication, inspection of critical components like rollers and cutting blades, and periodic cleaning are essential for optimal performance and longevity.

Yes, the machine typically comes with a 1-year warranty covering manufacturing defects and support.

Optional add-ons include automatic stackers, remote PLC systems, coil car tippers, and advanced speed upgrades for higher productivity.

Copyright 2026 © Machine Matcher.