To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

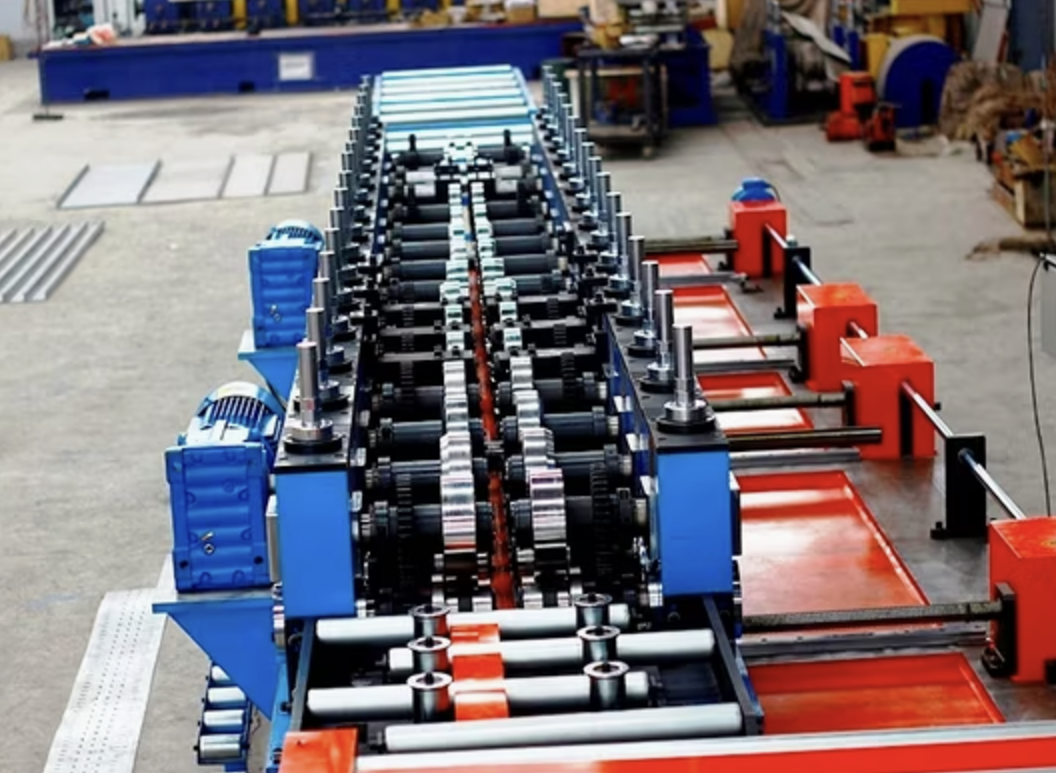

Cable tray roll forming machines are specialized equipment designed to produce high-quality cable trays efficiently and consistently. Cable trays are essential components in electrical and construction industries, offering organized and secure routing for cables in commercial, industrial, and residential installations. Germany's advanced industrial sector has a high demand for these machines, ensuring compliance with international quality standards and supporting large-scale infrastructure projects.

A cable tray roll forming machine is an automated system that transforms metal coils into finished cable trays through sequential roll forming stages. The machine integrates cutting, punching, and profiling operations, offering precision and customization for various cable tray designs such as perforated, ladder, or solid-bottom trays.

These machines cater to diverse requirements in terms of dimensions, load capacities, and material types, making them ideal for Germany's stringent construction and industrial needs.

Copyright 2026 © Machine Matcher.