To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

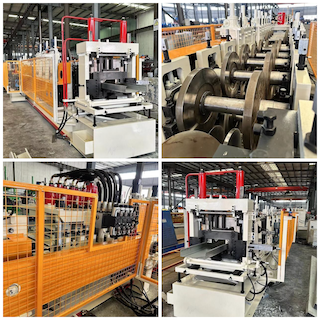

The Cee Purlin Roll Forming Machine is a highly efficient and versatile solution designed for manufacturing steel purlins in the construction and building industry. Located in Missouri, USA, this machine caters to local construction projects, delivering high-quality purlins used in metal buildings, roofing systems, and structural applications. Its robust construction, advanced automation, and flexibility make it ideal for manufacturing precision-engineered profiles that meet the demands of the U.S. market.

The machine produces Cee purlins commonly used in structural applications. Below are the key details:

Located in Missouri, USA, the machine is well-suited for local manufacturing industries, offering:

To ensure longevity and consistent performance:

Q: What is the forming speed of this machine?

A: The Cee Purlin Roll Forming Machine operates at a speed of 50-60 ft/min.

Q: Can the machine handle variable material thickness?

A: Yes, the machine is designed to process materials of varying thicknesses, making it versatile for different project needs.

Q: What are the power requirements for the machine?

A: The machine requires 32 Hp power with a 480V, 3-phase connection.

Q: Is this machine suitable for high-volume production?

A: Absolutely. With 21 forming stations and a forming speed of up to 60 ft/min, it is ideal for large-scale production.

Q: What kind of cutting system does it use?

A: The machine uses a hydraulic shear cutting system for precision and durability.

Q: Does it come with safety features?

A: Yes, the machine is equipped with safety covers to protect operators during operation.

Q: What industries commonly use Cee purlins?

A: Cee purlins are extensively used in construction for roofing systems, wall structures, and secondary framing.

Q: What support is available for setup and training in Missouri?

A: Local setup and training services are available in Missouri, along with technical support to ensure smooth operation.

Q: Can the profiles be customized beyond 5" to 12"?

A: While the standard range is 5" to 12", customizations may be possible depending on specific requirements. Please consult the manufacturer for details.

Copyright 2026 © Machine Matcher.